Tire pressure monitoring sensor and mounting method

a technology for monitoring sensors and tires, applied in the direction of tire measurement, vehicle components, transportation and packaging, etc., can solve the problems of sensor lifting or moving outwardly from the rim, loss of retention to the wheel, leakage of air, etc., and achieve the effect of preventing undesired movement during operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

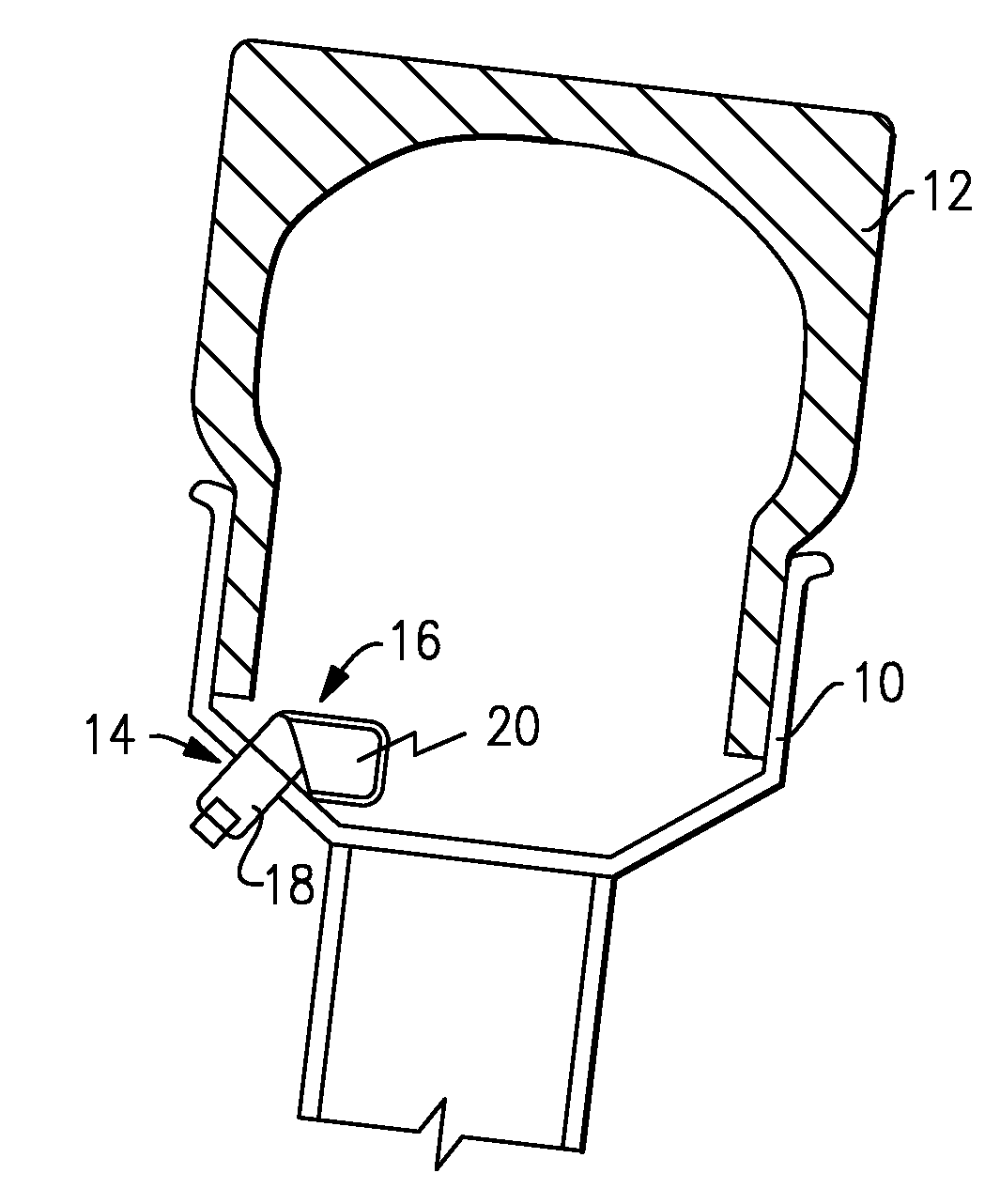

[0022]Referring to FIG. 1, a tire 12 is mounted to a wheel rim 10 and includes a tire pressure monitoring assembly 16. The tire pressure monitoring assembly 16 includes a valve stem 18 that extends through an opening 14 in the wheel rim 10 and a tire pressure sensor 20 that is attached to the valve stem 18. The sensor 20 is supported by the valve stem 18 that is in turn received and secured to the wheel rim 10 within the opening 14. The sensor 20 includes devices for monitoring and communicating conditions within the tire 12, such as pressure and temperature.

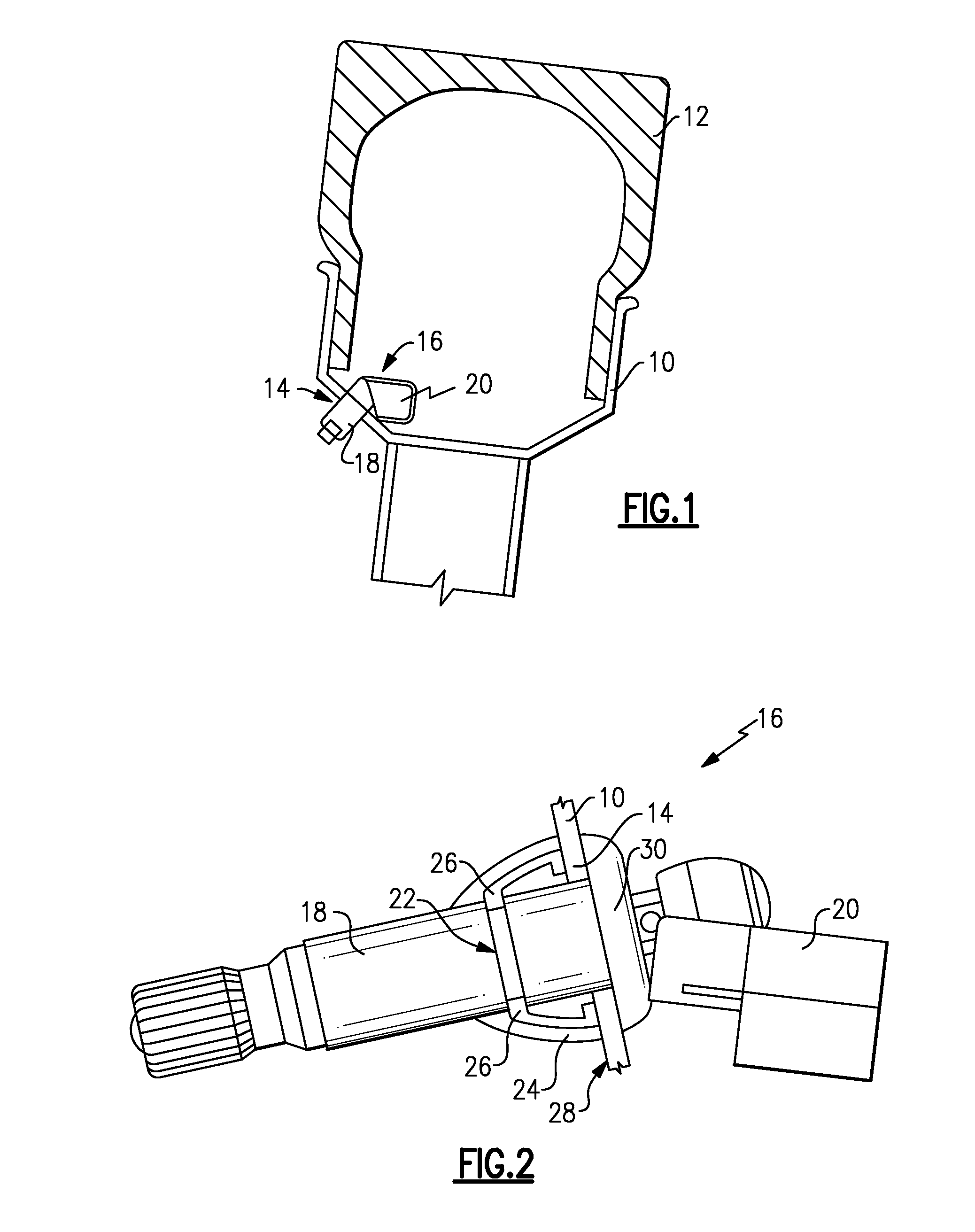

[0023]Referring to FIG. 2, the example tire pressure sensor assembly 16 includes a spring clip 26 that provides a biasing force against an outer surface 28 of the wheel rim 10. The valve stem 18 is disposed at least partially within a rubber housing 24. The rubber housing 24 is mounted to the opening 14 in the wheel rim 10 and remains in place due to the biasing force exerted by the spring clip 26. The rubber housing 24 also ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com