Quick assembly furniture

a technology for furniture and case goods, applied in the field of furniture case goods, can solve the problems of difficult management of fully assembled case goods, relatively high shipping and delivery costs, and inability to easily deliver fully assembled case goods to a customer's home, and achieve the effect of easy logistics and high level of fit and finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

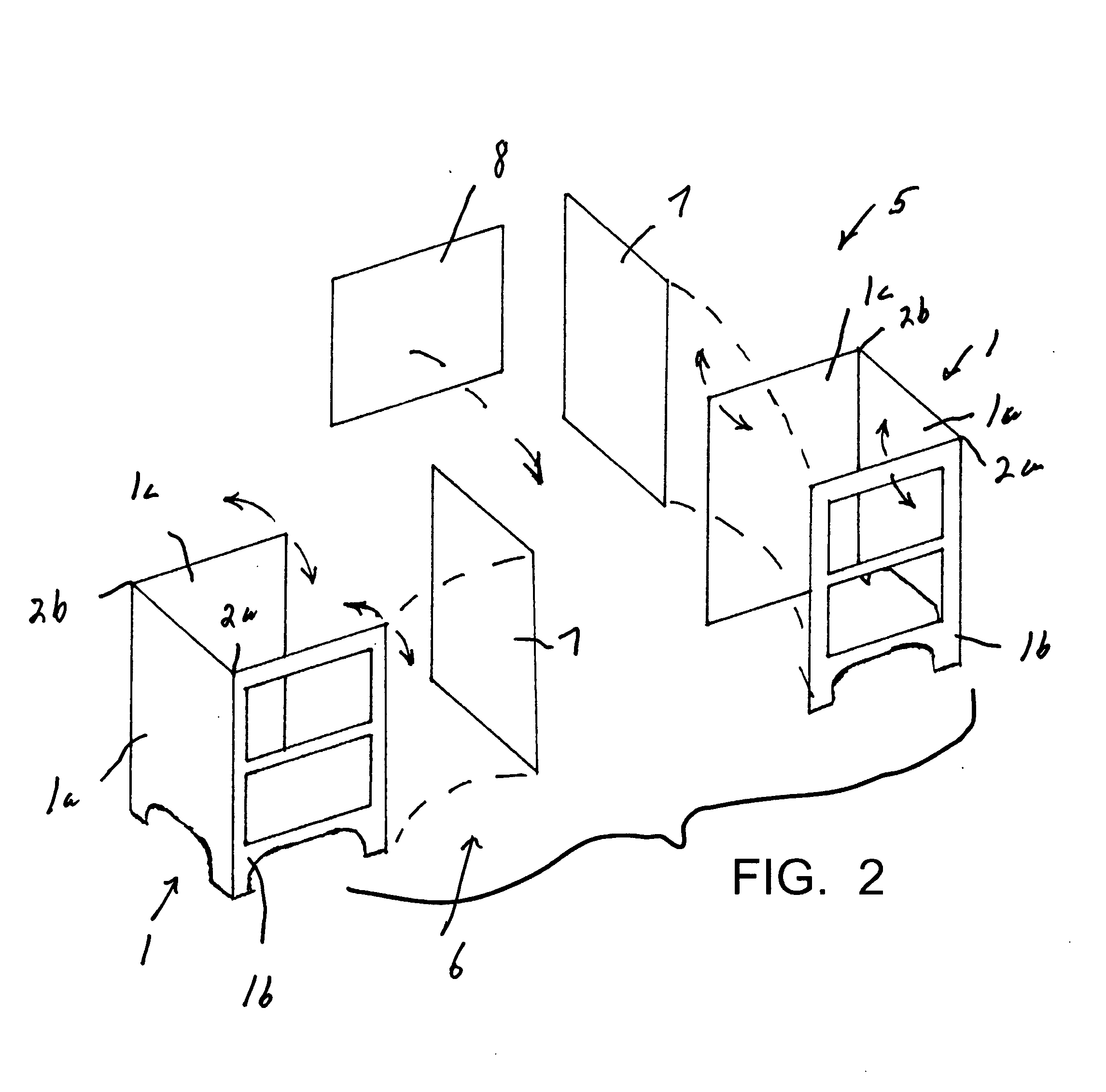

[0025]A preferred embodiment of quick assembly furniture according to the invention is generally shown in the drawing figures and discussed below. Generally, the inventive concept is premised on hinging multiple panels together sub-assemblies, configuring the sub-assemblies as desired in a partial finished case good configuration, and completing the case good with further panels or sub-assemblies.

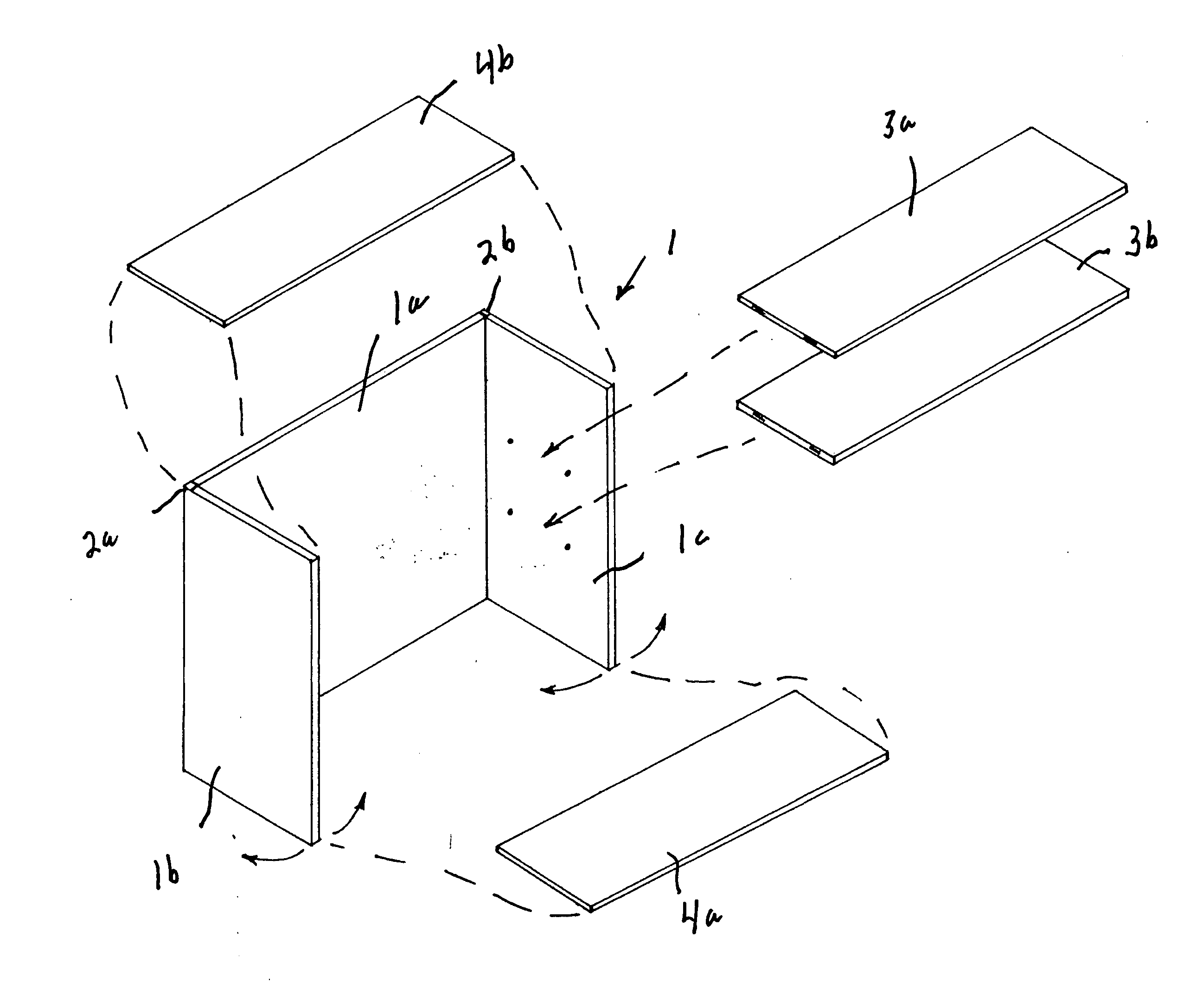

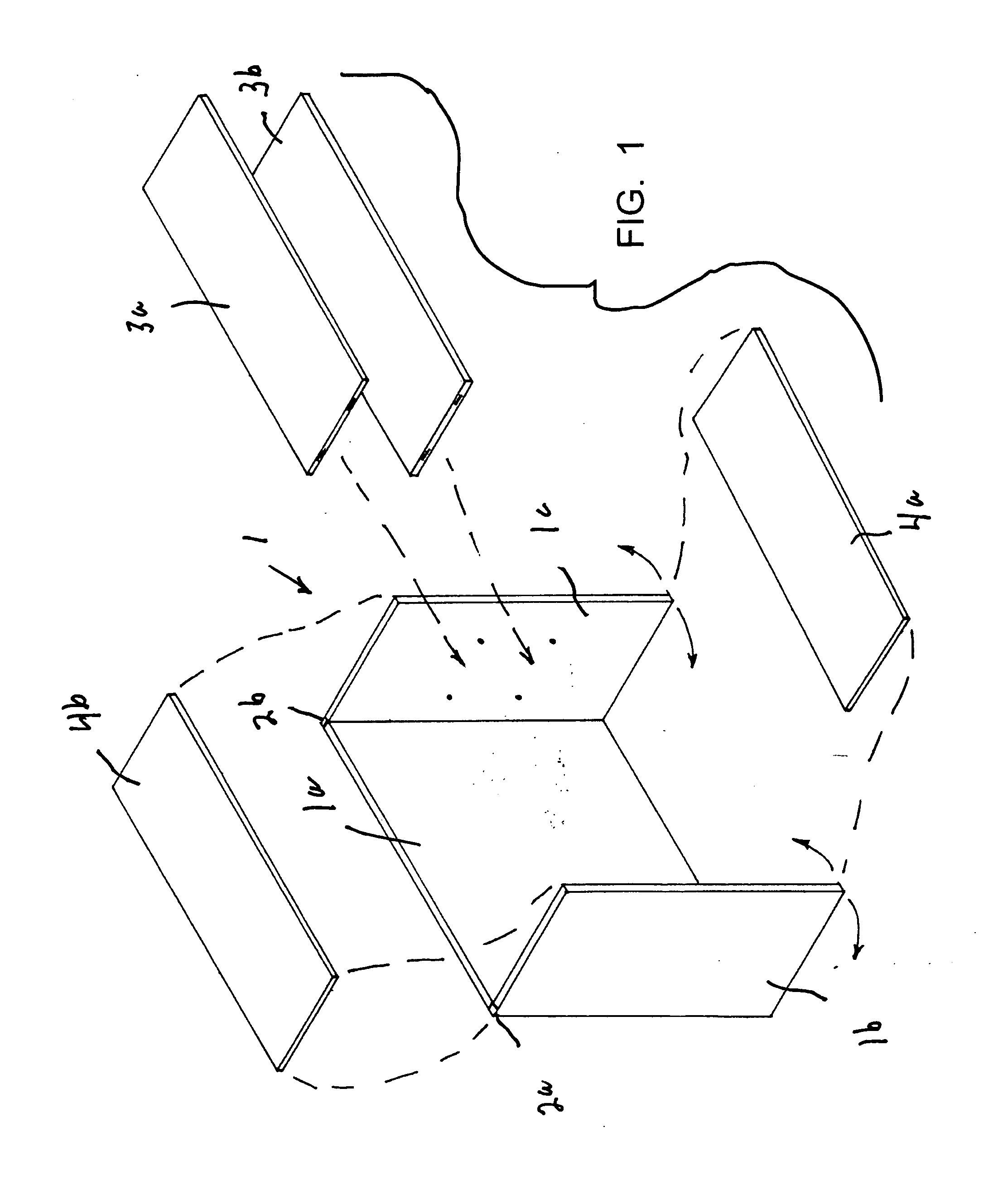

[0026]Thus, a bookcase of the invention may have a basic sub-assembly of a three sided furniture carcass 1 with a bight panel 1a and two wing panels 1b, 1c (FIG. 1). The bight panel 1a may have two opposing hinge edges 2a, 2b, and one of the wing panels 1b, 1c may be hinged with each of the hinge edges 2a, 2b. In assembly, the wing panels 1b, 1c hinge relative to the bight panel 1a to a generally U-shaped open sided case configuration as shown in FIG. 1. The wing panels 1b, 1c are noted to be generally parallel with one another and generally perpendicular to the bight panel 1a. Alternativel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com