Flat roof tile with integrated photovoltaic module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

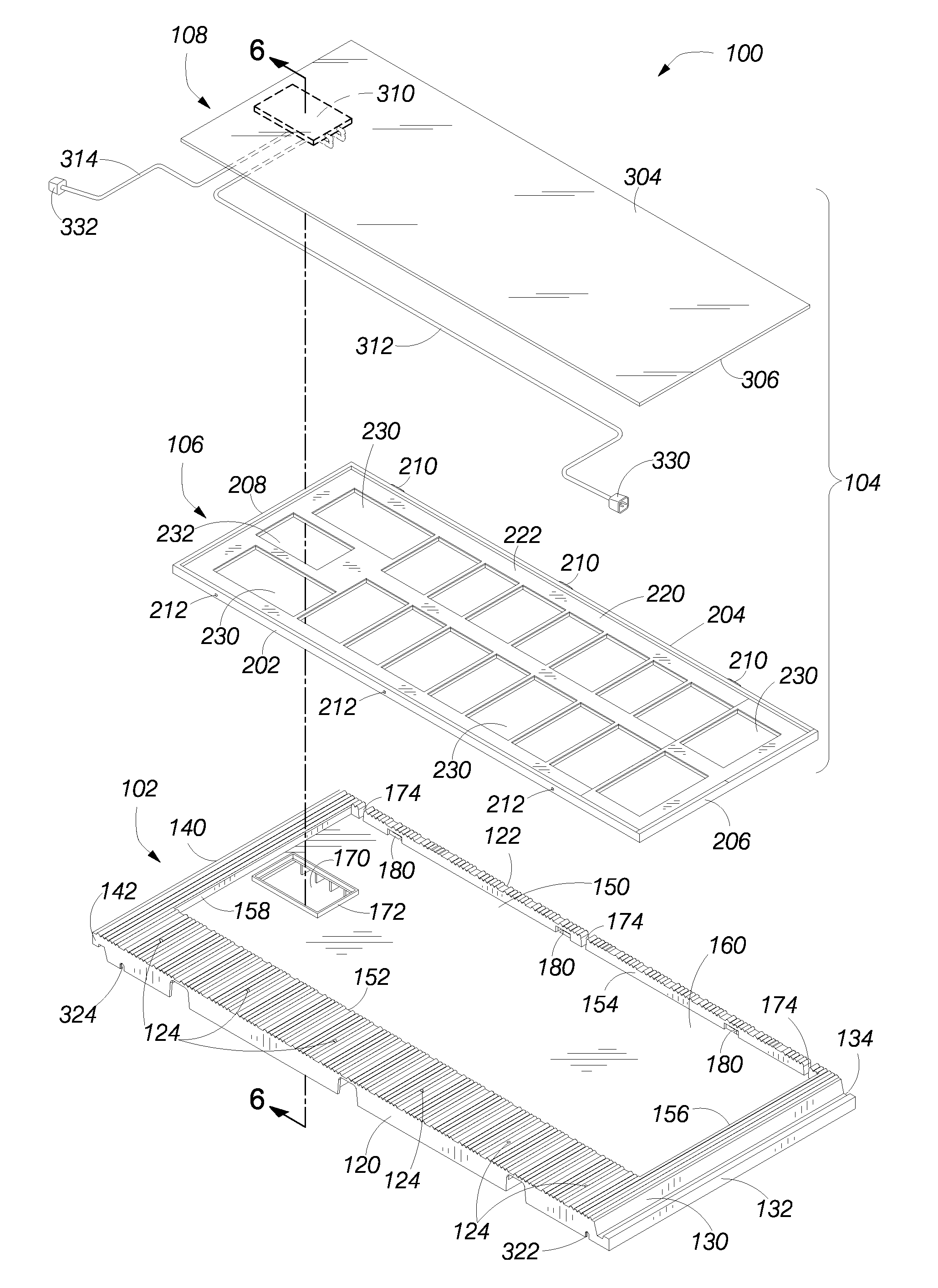

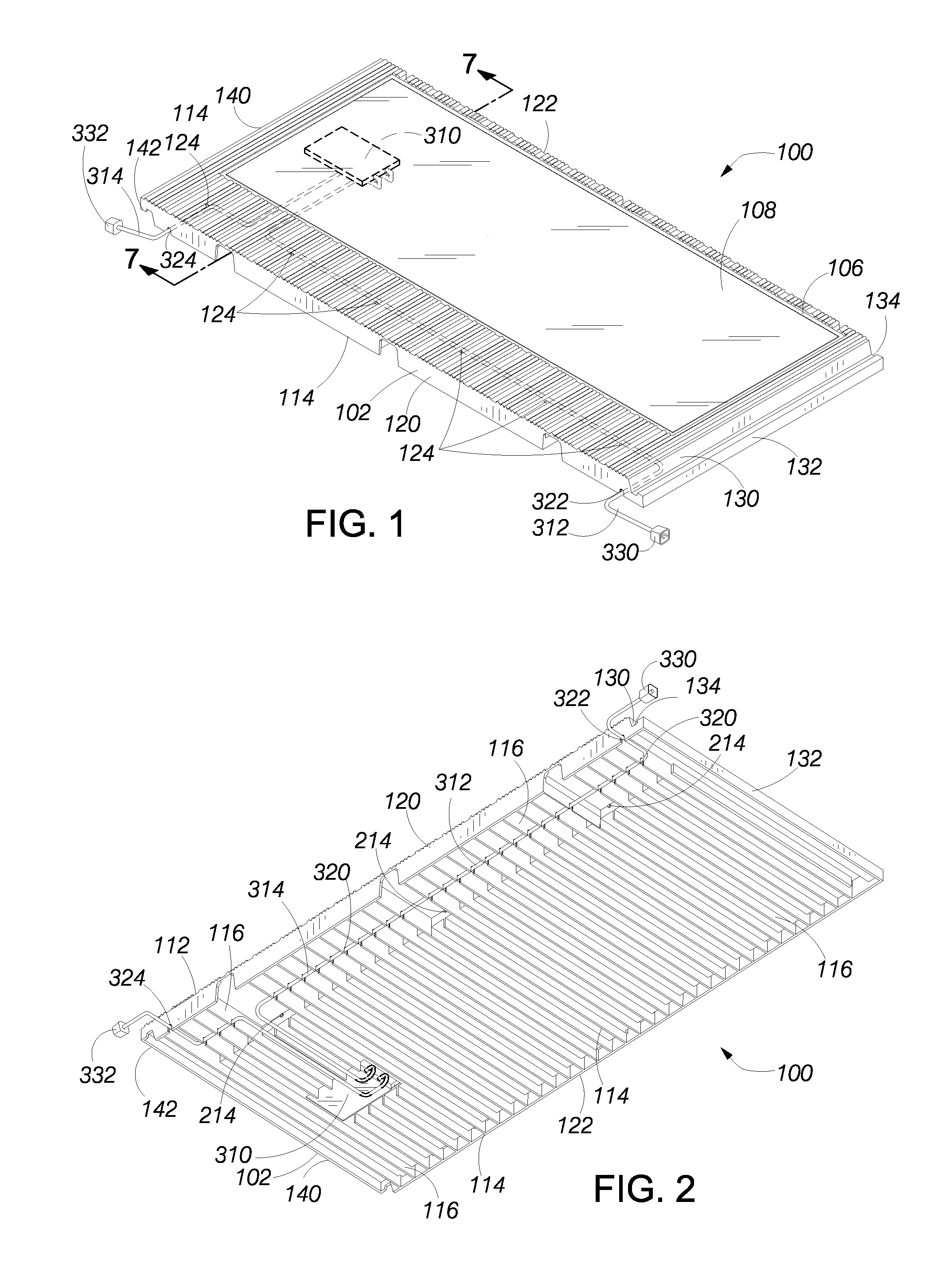

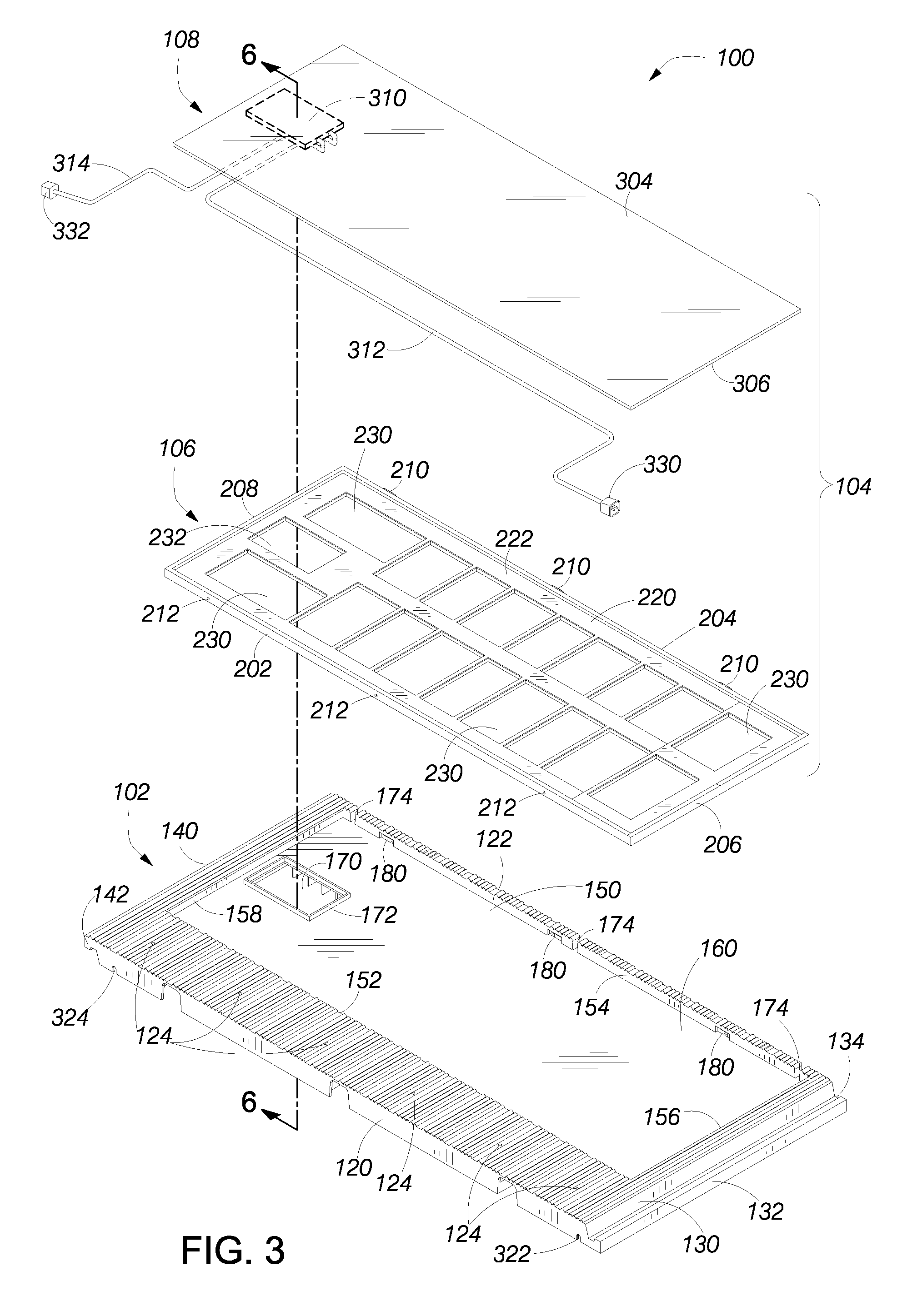

[0018]FIGS. 1-7 illustrate an embodiment of a flat solar panel tile 100 suitable for mass production using injection molding techniques. The solar panel tile 100 comprises a tile base 102 and a solar panel assembly 104. The solar panel assembly comprises a solar panel support frame 106 and a photovoltaic panel (solar cell array) 108.

[0019]The tile base 102 is sized and shaped to conform to the size and shape of a conventional flat concrete tile configured to simulate the aesthetic appearance of a slate tile. In particular, the tile base has a plurality of striations (e.g., closely spaced grooves and ridges) formed on an exposed top surface 112 that are similar to the grooves on a concrete tile so that the top surface provides a “slate-like” appearance when viewed from a distance. An opposing bottom surface 114 (FIG. 2) of the tile base is formed as a plurality of strengthening ribs 116. Preferably, the tile base comprises injected molded plastic.

[0020]In the following description, “...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com