Bead string

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

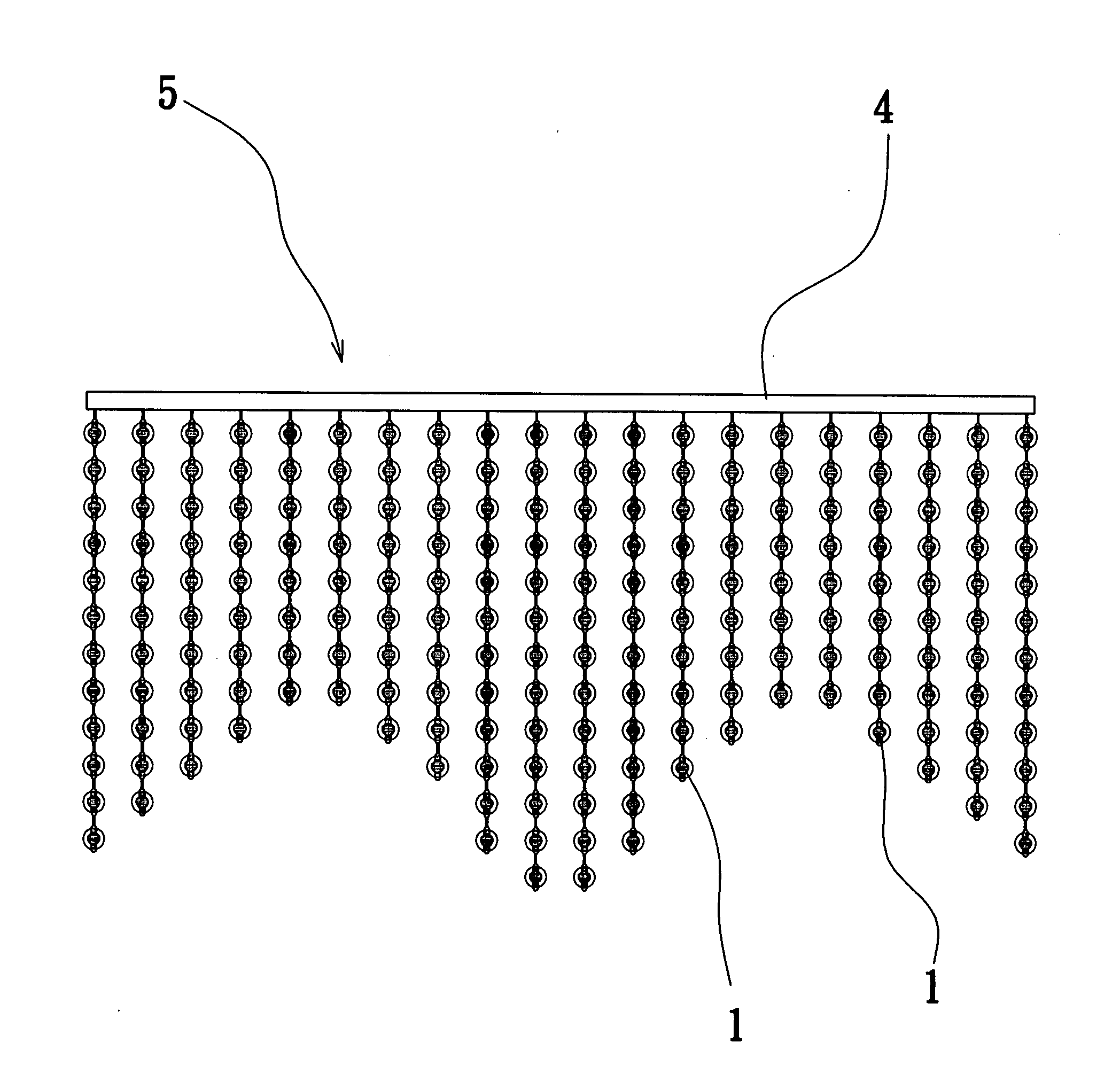

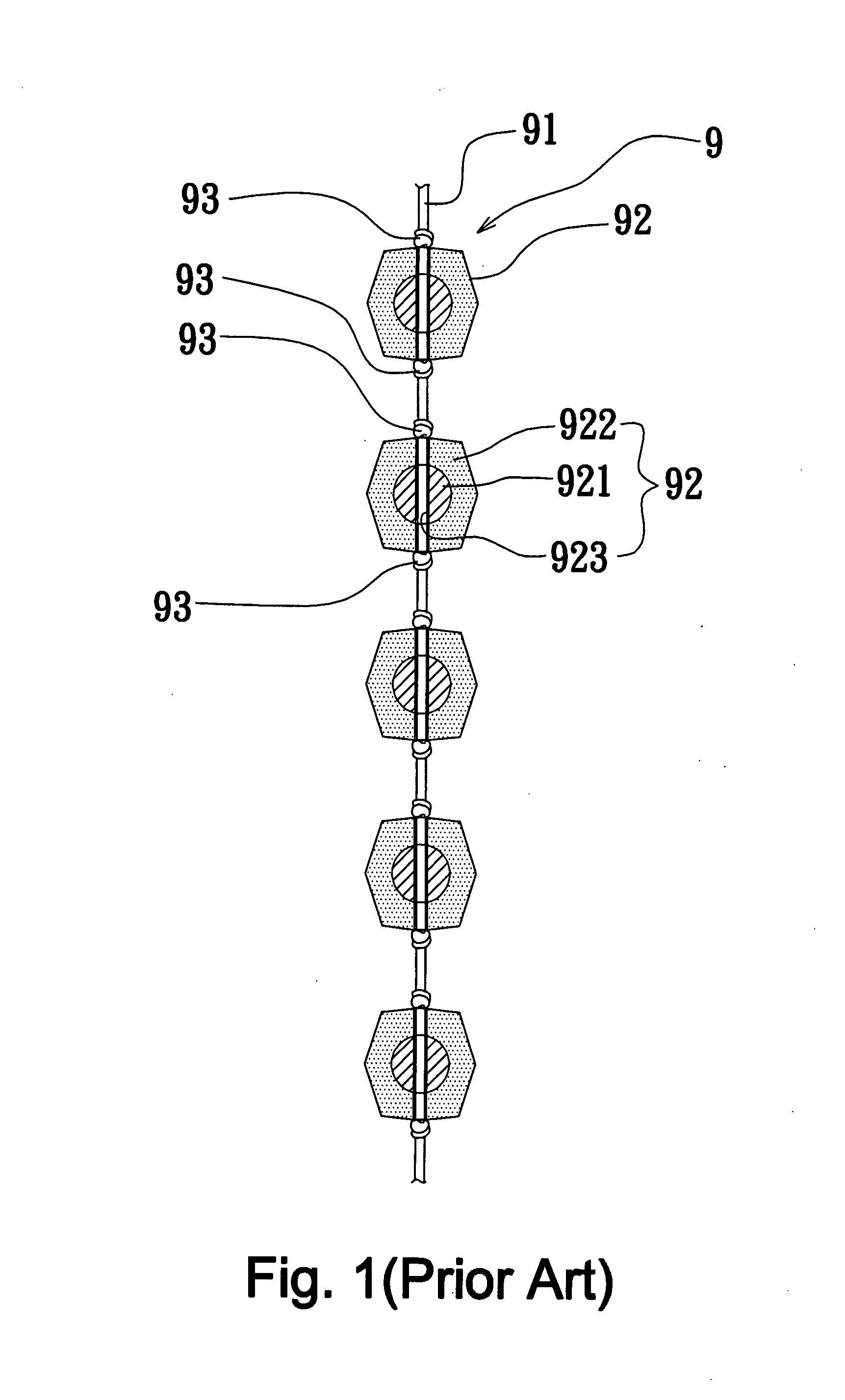

[0016]Referring to FIG. 3 for a preferred embodiment of the present invention, a bead string (1) is essentially comprised of a thread element (2) and multiple beads (3). The thread element (2) may be made of woven, non-woven, metal, plastic or any other equivalent material, and a cotton yarn is preferred; those beads (3) are spaced at intervals and firmly attached to the thread element (2); each bead (3) contains one or a plurality of inner layer (31) and one or a plurality of first outer layer (32).

[0017]The inner layer (31) is molded by injecting a plastic material into a first cavity where the thread element (2) passes through (not illustrated); and the molded inner layer (31) when cooled down to tightly cover up the thread element (2); in the preferred embodiment, the inner layer (31) is comprised of a bulb (311) and two pillars (312) respectively extending from an upper end and a lower end of the bulb (311); and the bead (3) is prevented from easily moving or falling off by tig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap