Systems and methods for hinged bedding assemblies

a technology of hinged bedding and mattress, which is applied in the direction of beds, couches, sofas, etc., can solve the problems of reducing the lifespan of mattresses, reducing the use of stabilizing and reinforcing structures, and reducing mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011]The foregoing and other objects and advantages of the invention will be appreciated more fully from the following further description thereof, with reference to the accompanying drawings wherein;

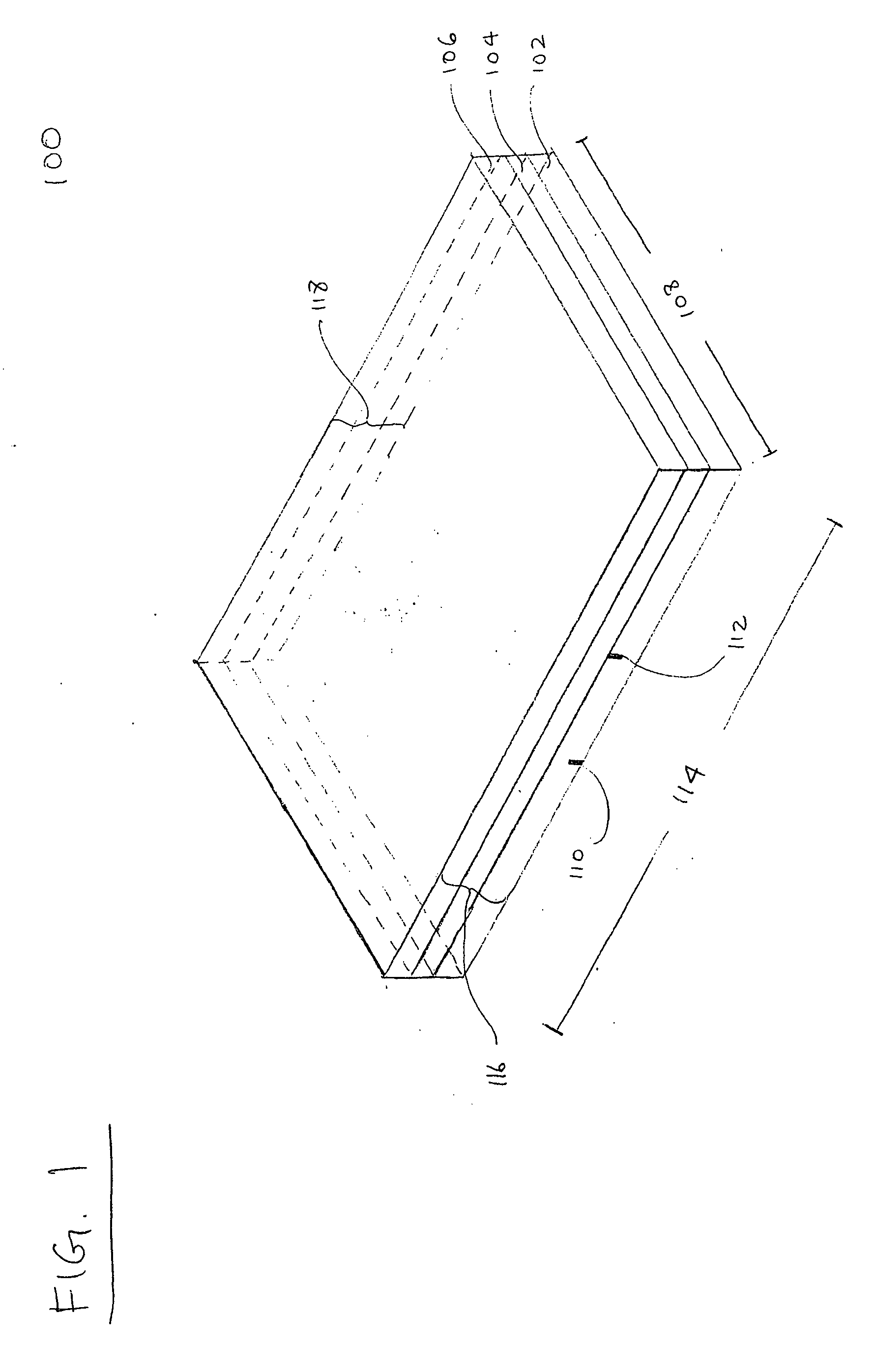

[0012]FIG. 1 is a perspective view of an adjustable mattress, according to an illustrative embodiment of the invention.

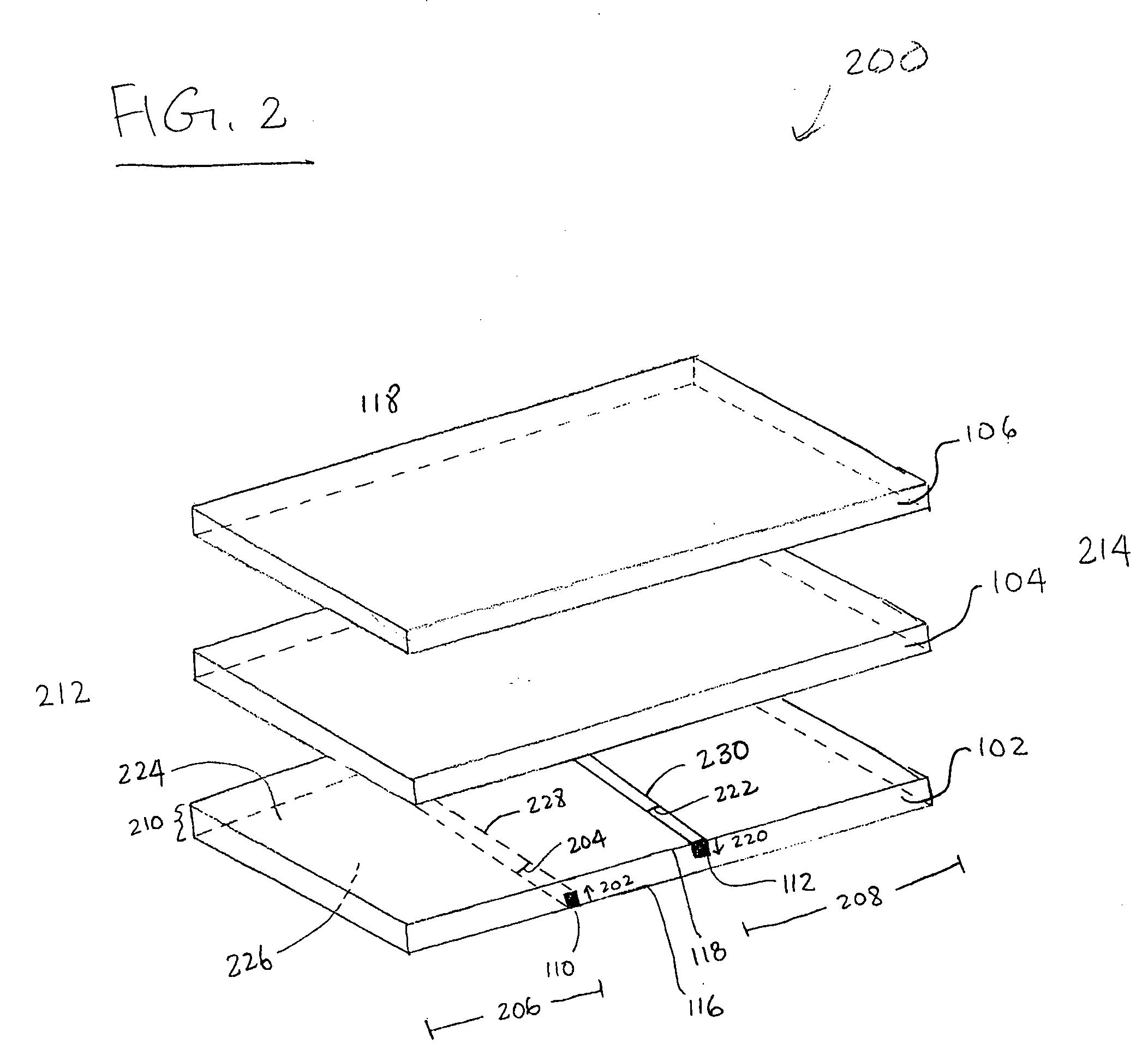

[0013]FIG. 2 illustrates an unassembled view of the mattress of FIG. 1, according to an illustrative embodiment of the invention.

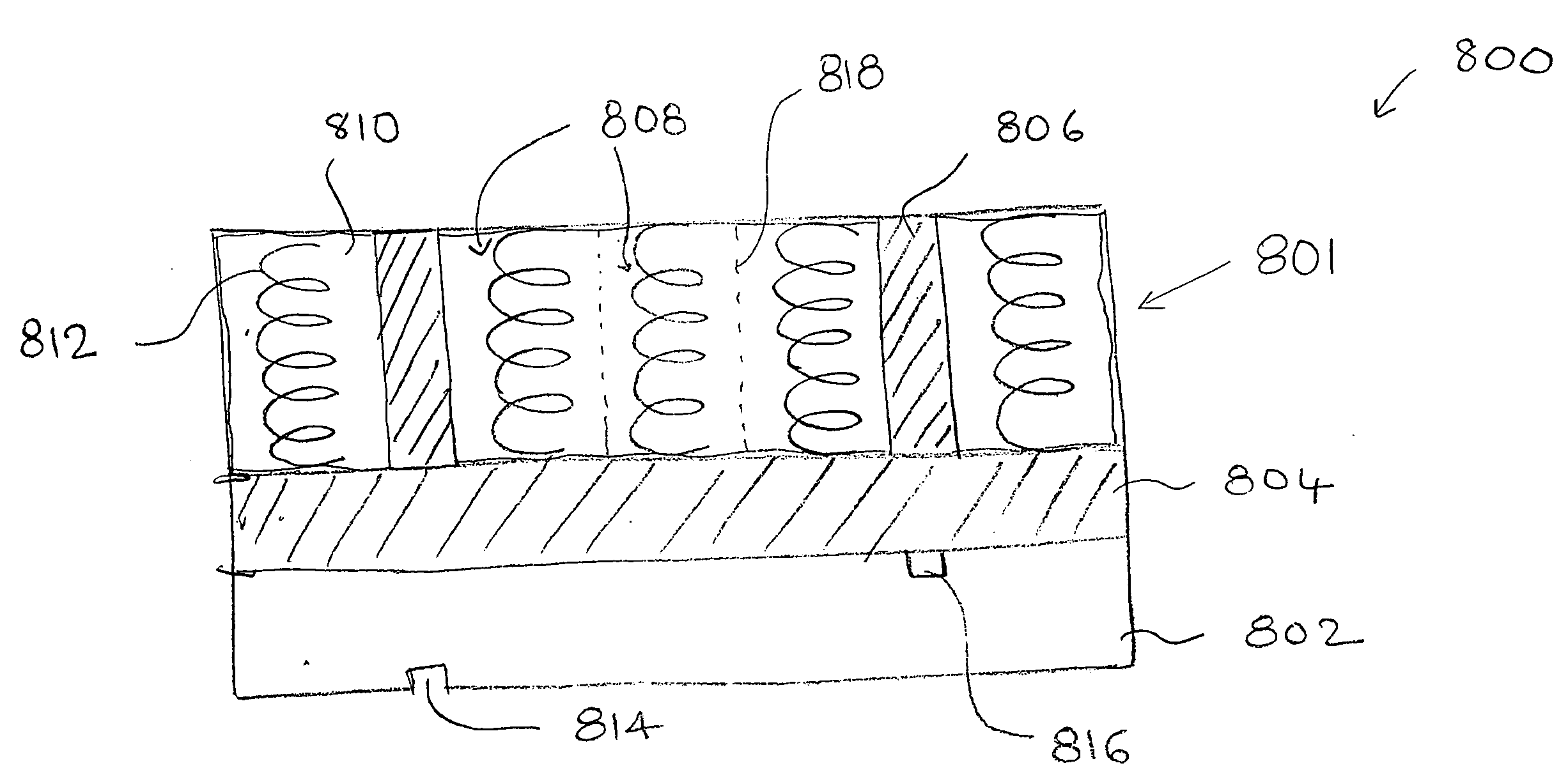

[0014]FIG. 3 is a perspective view of the mattress in operation, according to an illustrative embodiment of the invention.

[0015]FIGS. 4A and 4B depict a cross-section view of mattresses, according to an illustrative embodiment of the invention.

[0016]FIG. 5 depicts a cross-section view of mattresses, according to an illustrative embodiment of the invention.

DESCRIPTION OF THE PREFERRED EMBODIMENT

[0017]To provide an overall understanding of the invention, certain illustrative embodiments will now be described, including an articulated hinged mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com