Compact Drain Assembly for Sinks and the Like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

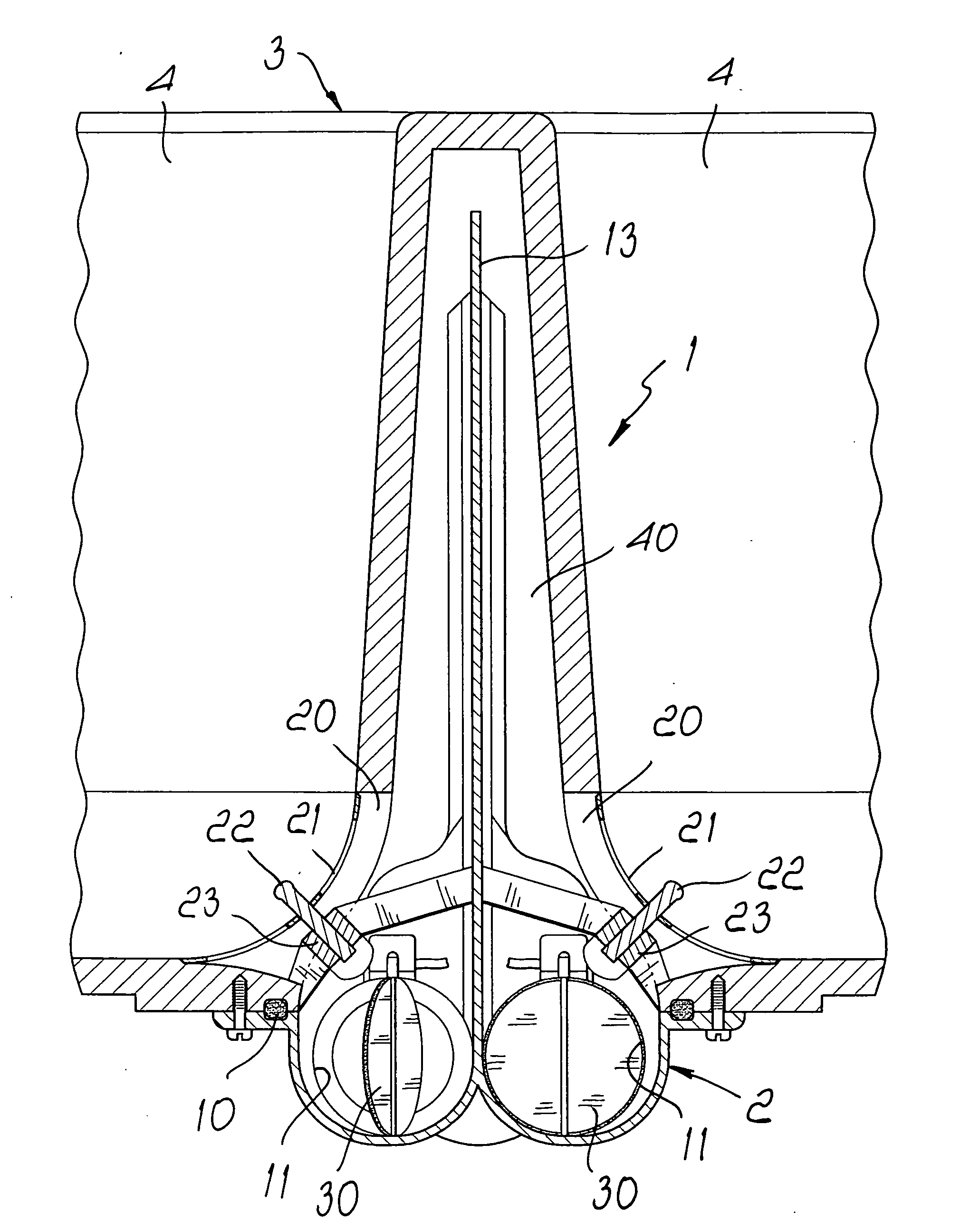

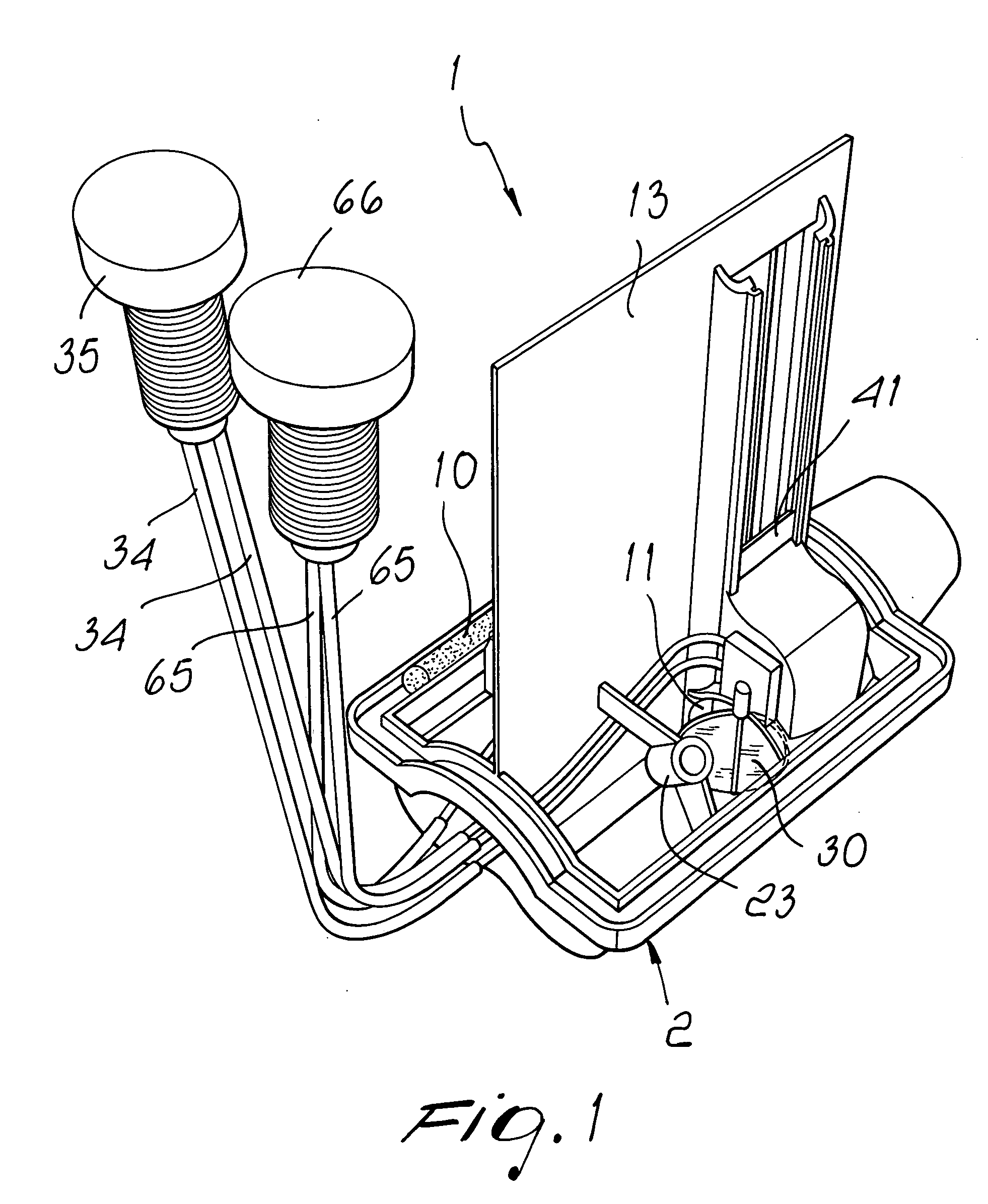

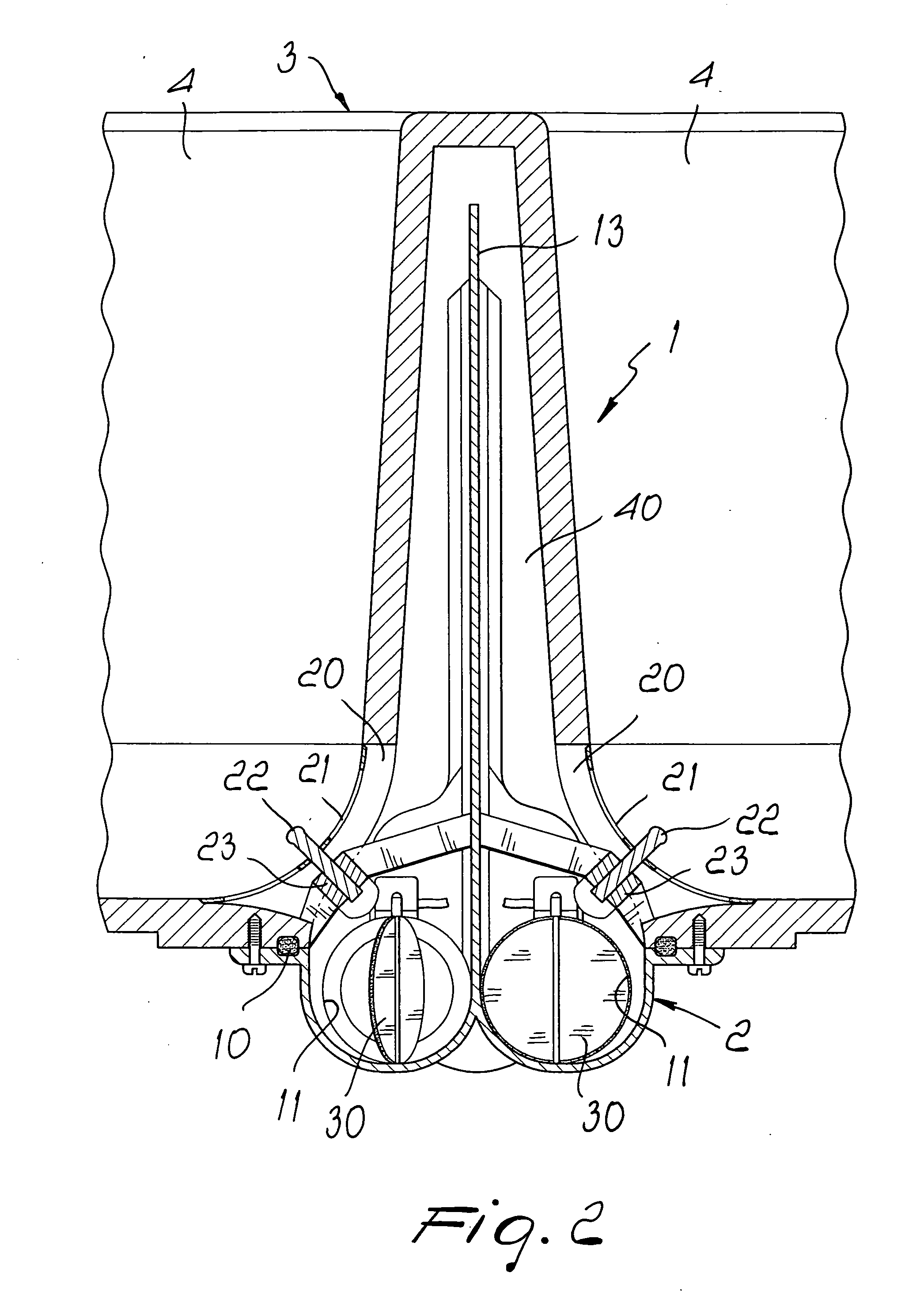

[0020]With reference to the figures, the compact drain assembly for sinks and the like, generally designated by the reference numeral 1, comprises a bowl element 2, which can be applied hermetically to a sink and the like, generally designated by the reference numeral 3, preferably at the region between the two bowls 4 of a sink or, in the case of a single-bowl sink, on the side of a bowl 4.

[0021]The bowl element 2 is provided with a sealing gasket 10, which acts on the outer surface of the sink 3 so as to optimize the hermetic coupling.

[0022]The sink 3 is connected to a drain duct 11, which is provided so that it has a drain duct 11 for each bowl 4.

[0023]In the case of two bowls, as shown schematically in FIG. 1, there are two ducts 11, which are mutually separated by a partition wall 13 which substantially divides the region arranged between the two bowls.

[0024]A peculiar feature of the invention consists in that each drain duct 11 is connected to a respective bowl 4 by means of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com