Outsole structure for a shoe, method for assembling outsole to an upper, and shoe obtained by said method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

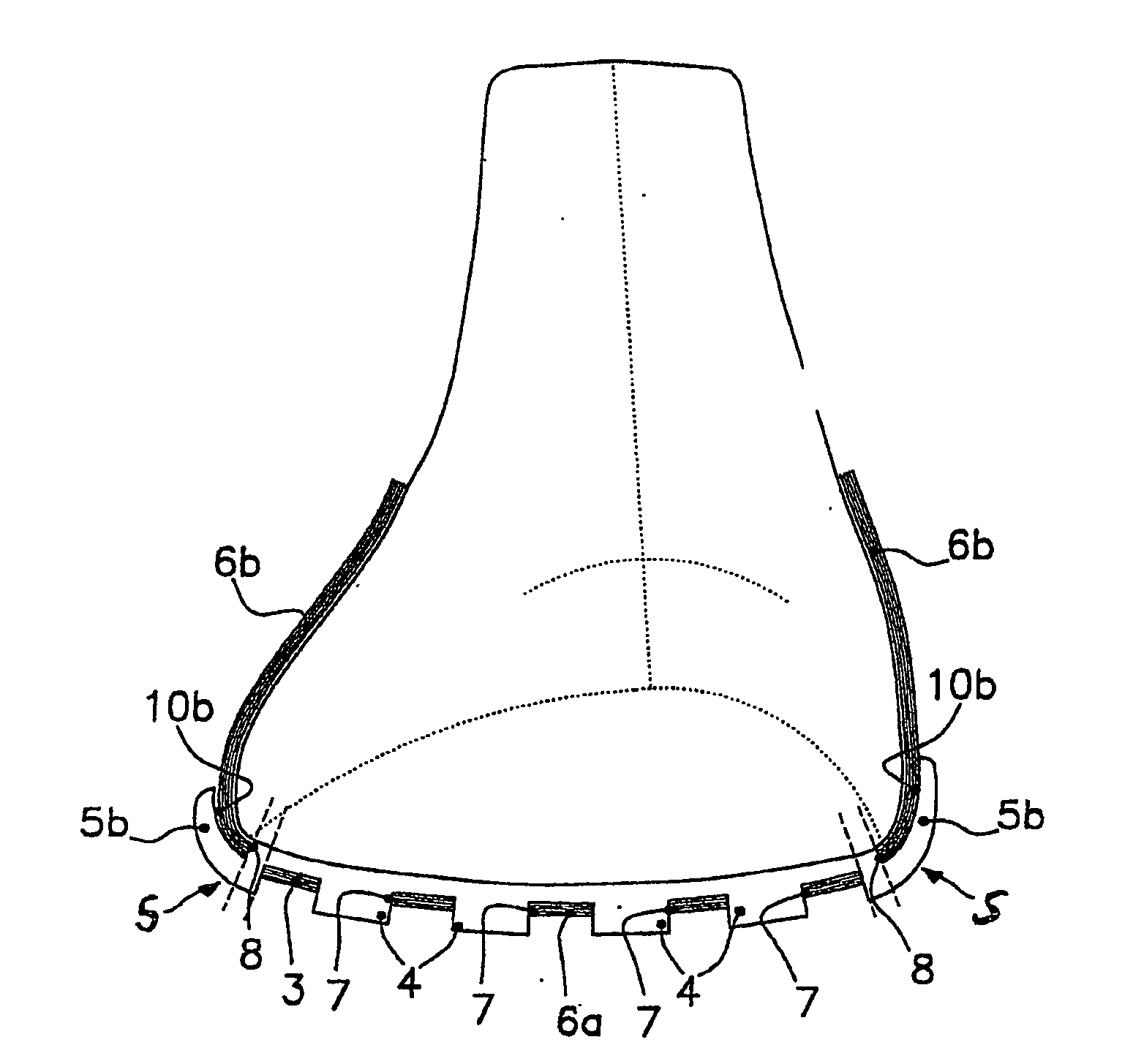

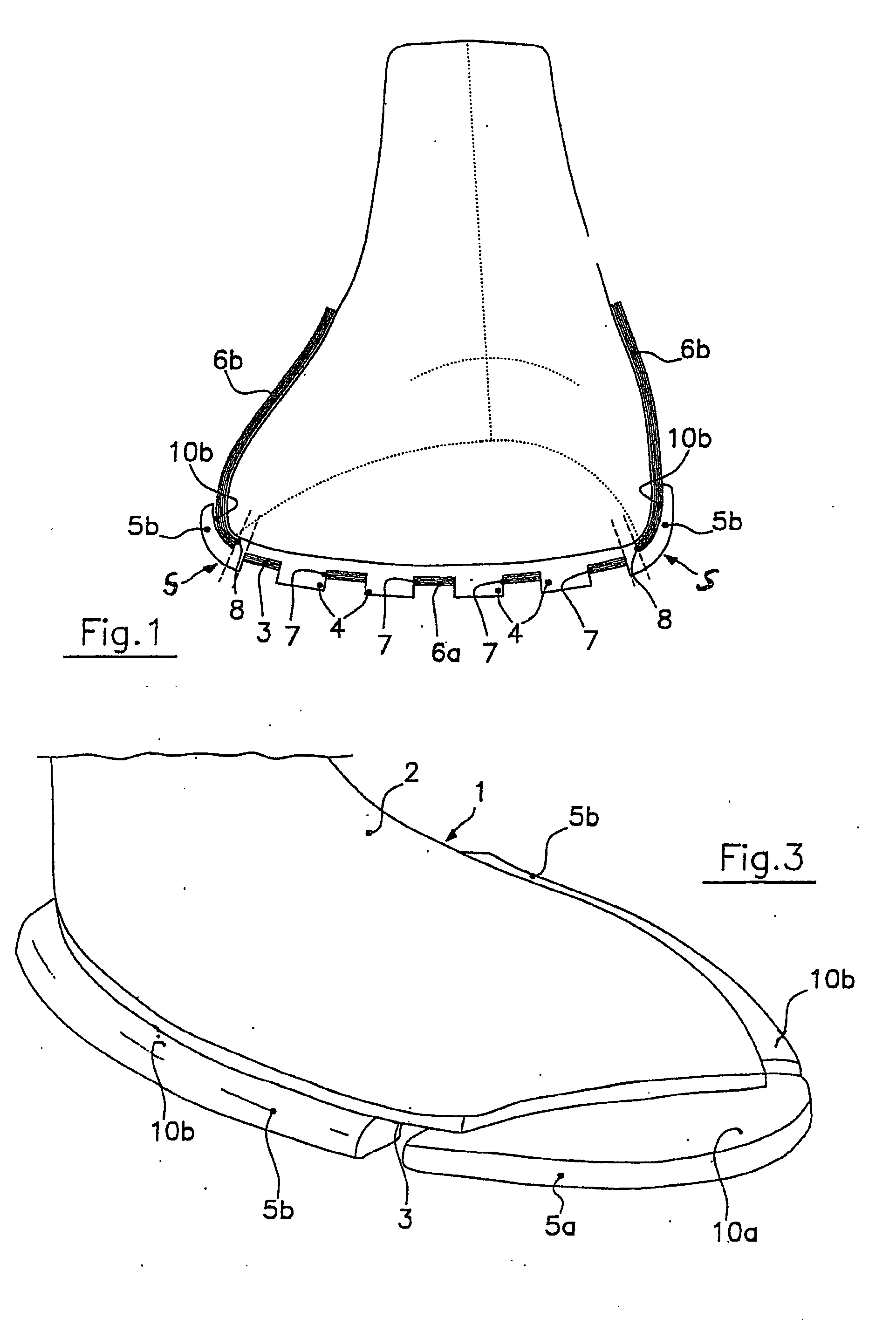

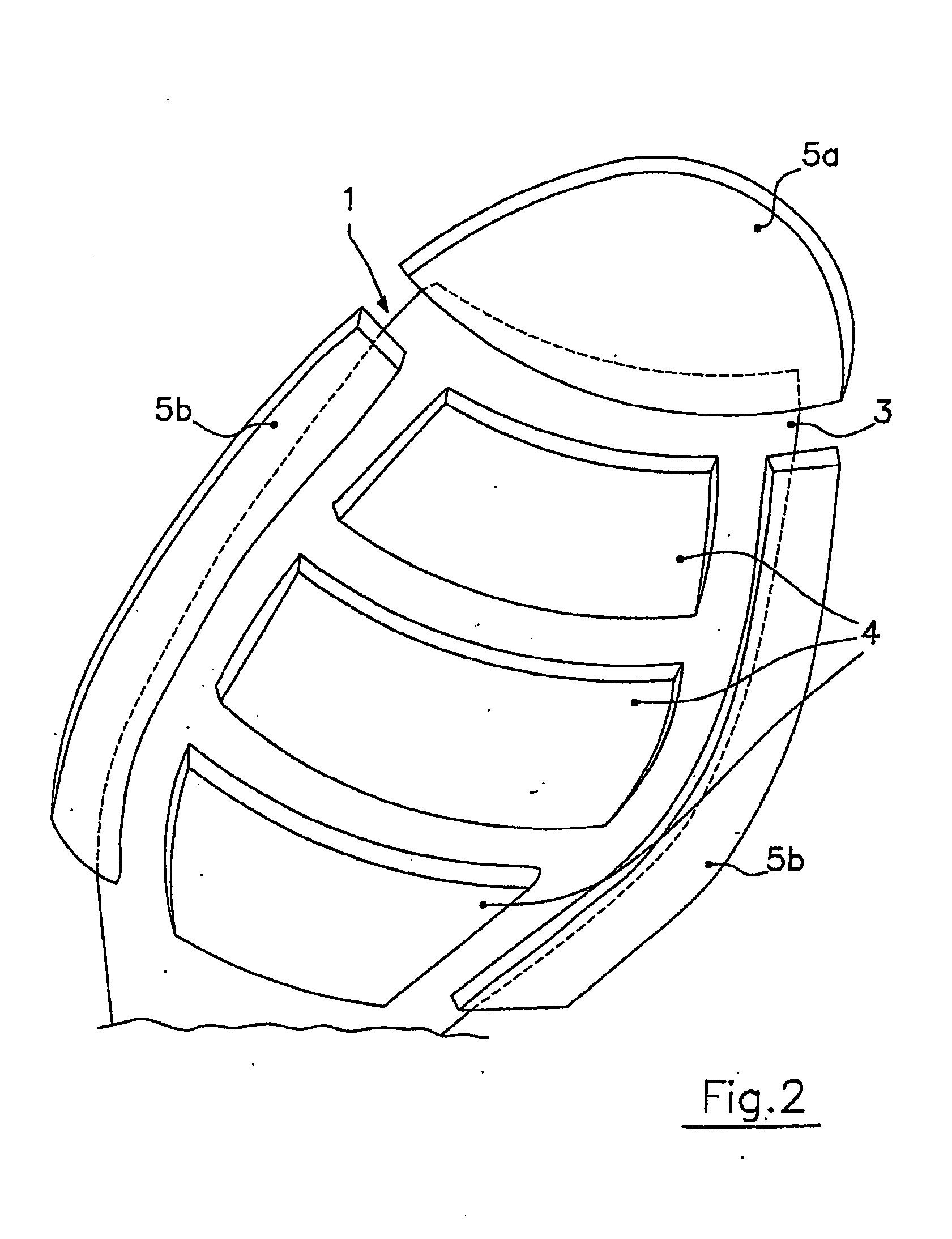

[0013]With reference to FIGS. 1 to 4, an outsole for a shoe according to the invention comprises a body 1 with substantially flat development, made of natural or synthetic rubber, shaped in accordance with the outline of the entire shoe sole or of just a portion thereof (for example the tip). In this second case, the shoe sole will be provided with two (or more) outsole semi-components physically separate from one another.

[0014]Body 1 therefore exhibits a top face 2, smooth in the schematic representation of FIG. 2 but which could actually be grooved or cut in various ways, intended for the foot's support with the interposition of an inter-sole and / or insole. Body 1 further exhibits a lower face 3 from which a distribution of protrusions projects, adapted for defining the actual sole tread. Among these protrusion, protrusions 4 can be noticed arranged in the inner zone of the lower face 3, that is, in a substantially central position, and peripheral protrusions 5, arranged along the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com