Self-adjusting torque device

a torque device and self-adjusting technology, applied in mechanical equipment, transportation and packaging, hoisting equipment, etc., can solve the problems of inability to smooth and gradual change, inability to feed and recover winding materials, and abrupt changes in torque variations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

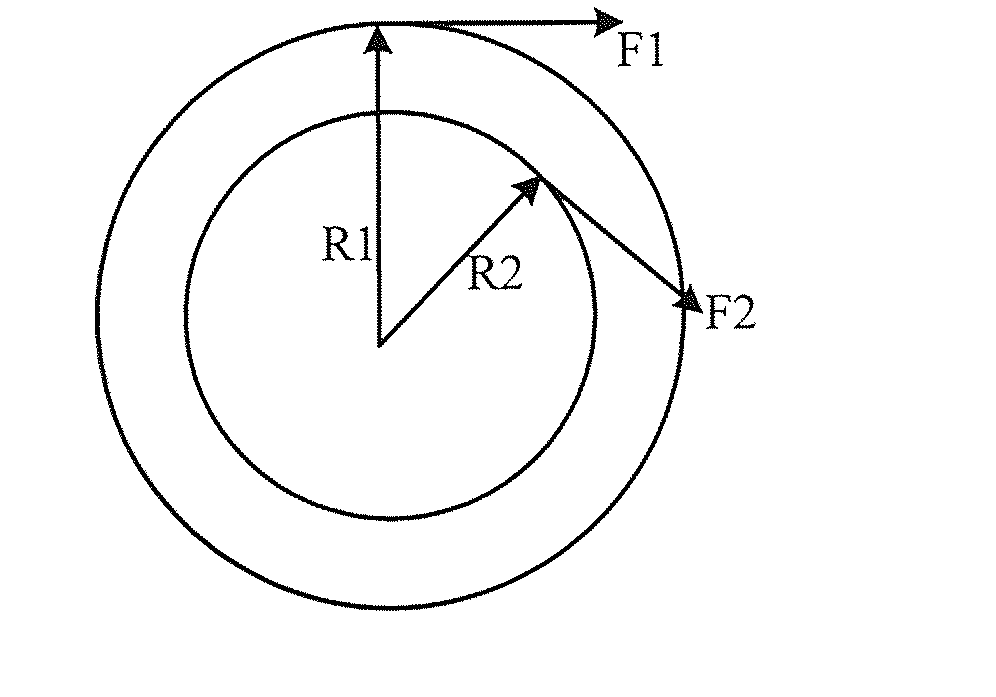

[0014]The implementations of the present invention provide a self-adjusting torque device so as to address the problem that the tension is not stable during feeding or recovering of a winding material in the related art, realize automatic adjustment of the torque of a material feeding or recovering device, keep the tension stable and guarantee accuracy of feeding or recovering the material.

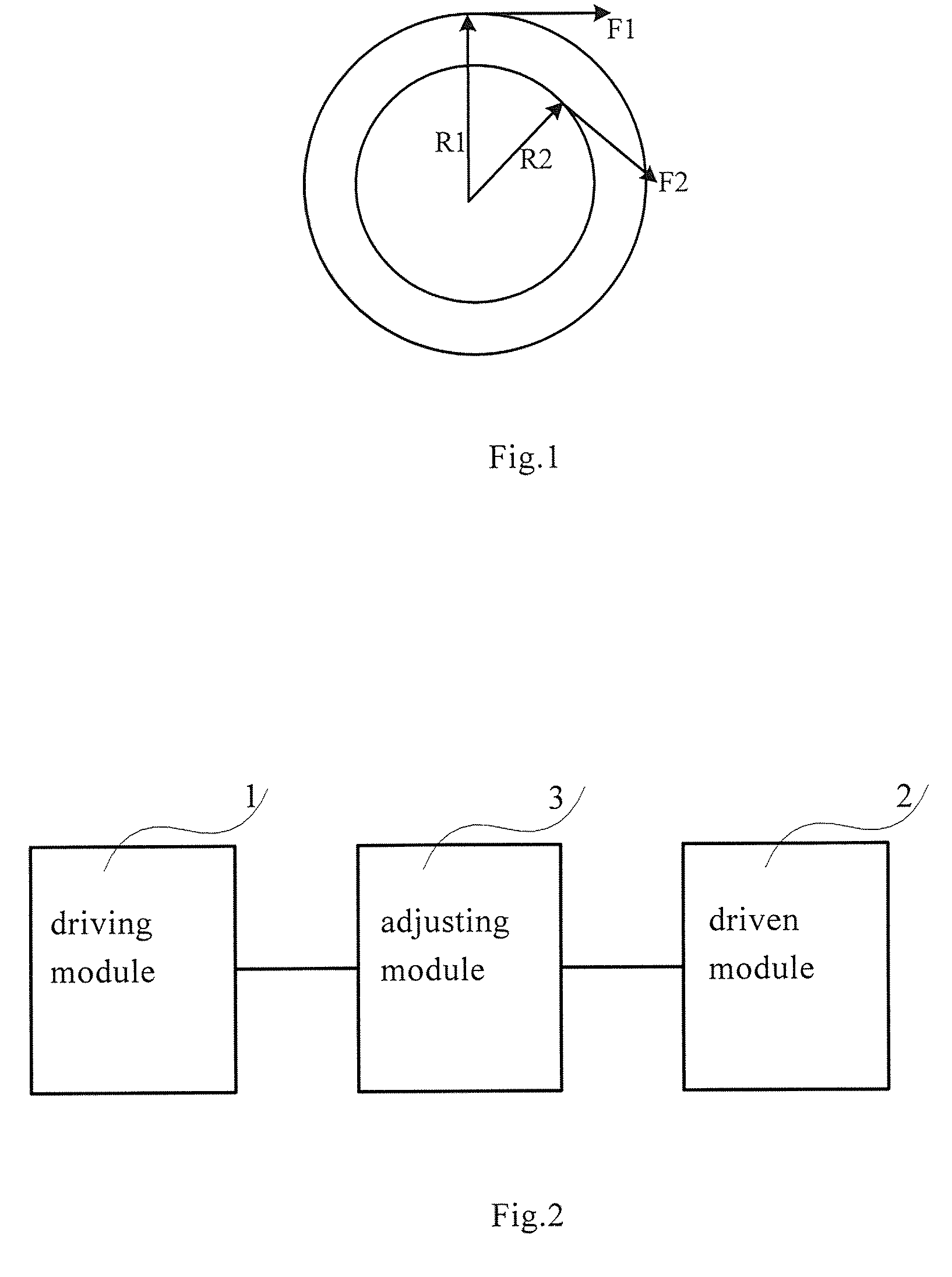

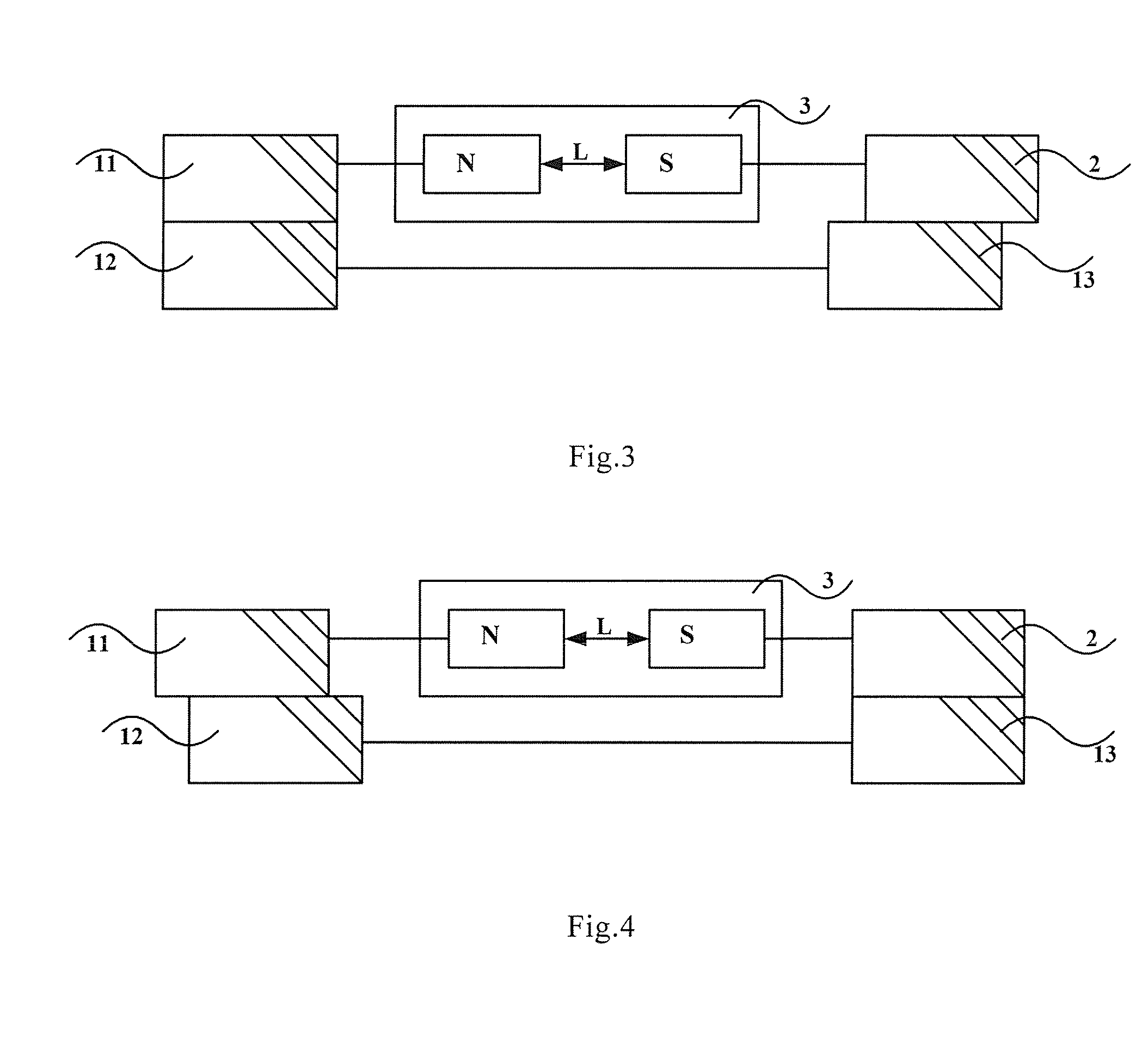

[0015]FIG. 2 is a diagram illustrating a self-adjusting torque device according to an embodiment of the present invention. As shown in FIG. 2, the self-adjusting torque device includes: an driving module 1 for introducing an external power and having a first tension; a driven module 2 connected to a winding material, reflecting a second tension acting on the winding material; and an adjusting module 3 connected to both of the driving module 1 and the driven module 2, for receiving the first and the second tensions and self-adjusting the second tension to keep it consistent with the first tension.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com