Liquid flowing device

a technology of liquid flowing and spherical fluid, which is applied in the direction of positive displacement liquid engines, piston pumps, machines/engines, etc., can solve the problems of propeller mechanism limitation, seal obstruction, and pump size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]A preferred embodiment of the invention is described below with reference to the accompanying drawings. It is noted that the embodiment described below explains an example of the invention.

[0039]1. Liquid Flowing Device

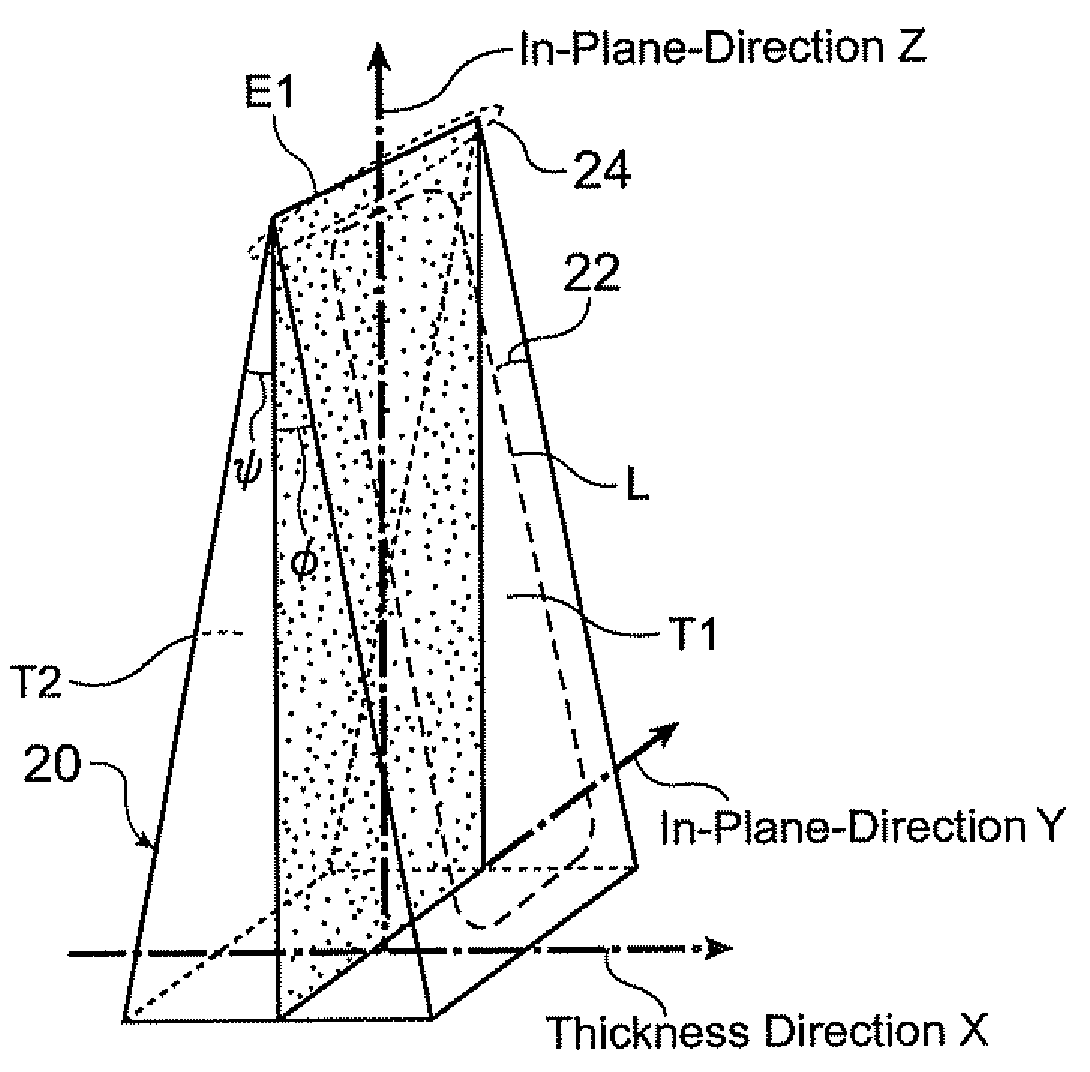

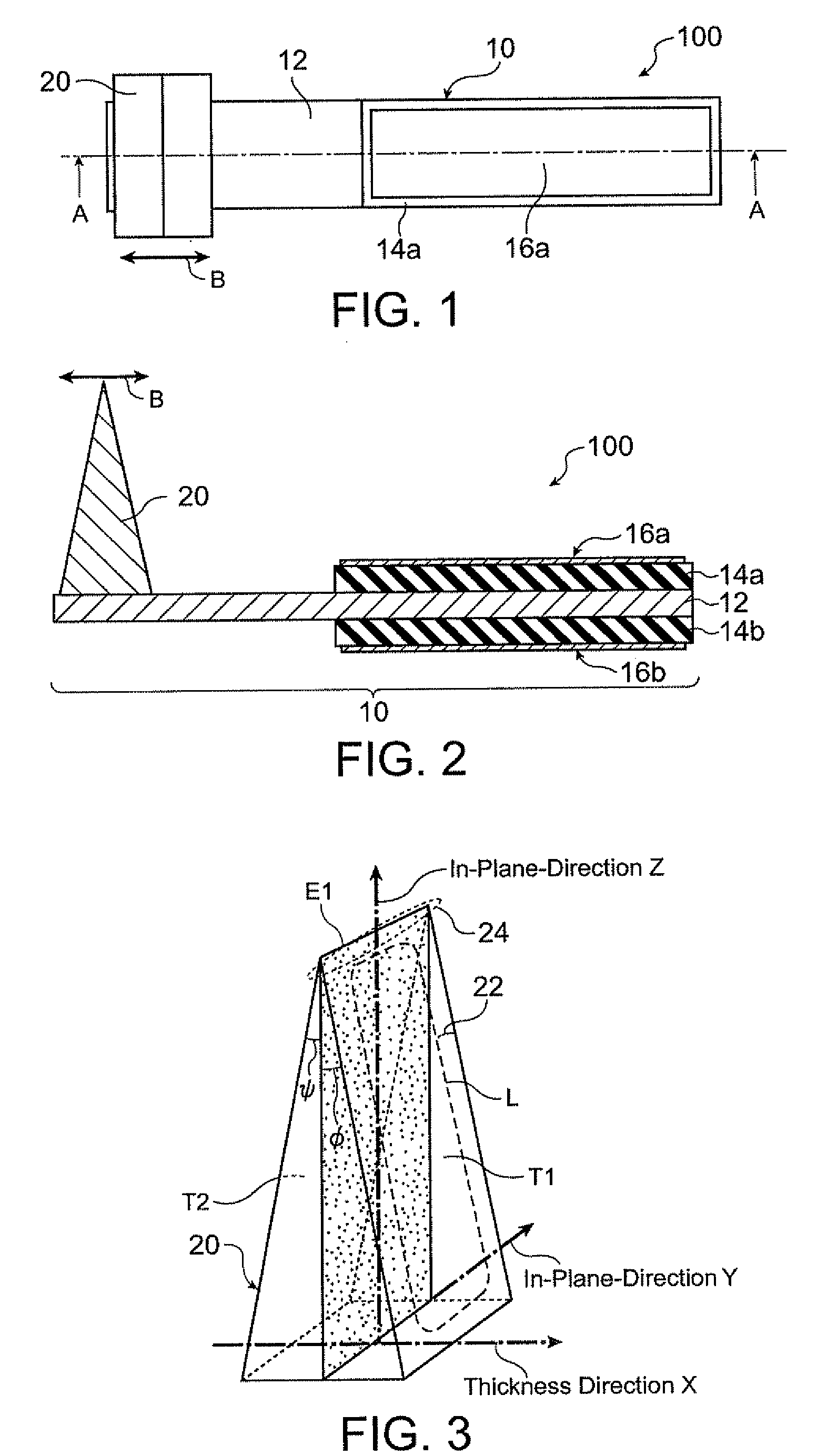

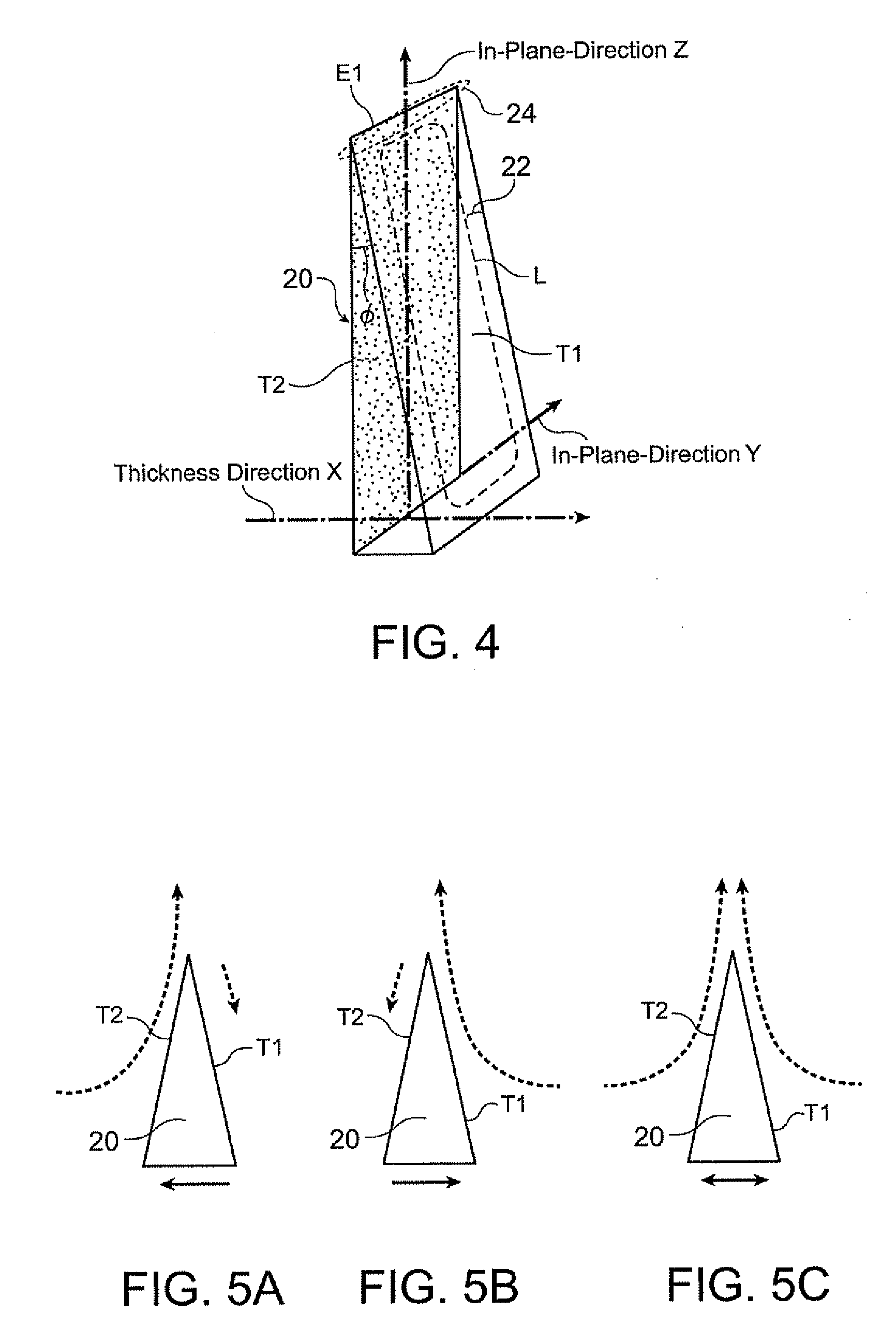

[0040]An example of a liquid flowing device 100 in accordance with an embodiment of the invention is described with reference to the accompanying drawings. FIG. 1 is a schematic plan view of the liquid flowing device 100 in accordance with the present embodiment. FIG. 2 is a schematic cross-sectional view of the liquid flowing device 100 in accordance with the embodiment of the invention. A cross section taken along a line A-A of FIG. 1 corresponds to FIG. 2. FIG. 3 and FIG. 4 are schematic perspective views of examples of driving sections 20 in accordance with the embodiment, respectively.

[0041]The liquid flowing device 100 has a driving section 10 and a vibration body 20.

[0042]The driving section 10 includes piezoelectric layers 14a and 14b with a base member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com