Valve timing adjusting apparatus

a timing adjustment and valve technology, applied in mechanical equipment, valve arrangements, machines/engines, etc., can solve the problems of increased sleeve size, complex configuration, and inability to adjust the axial hole length,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

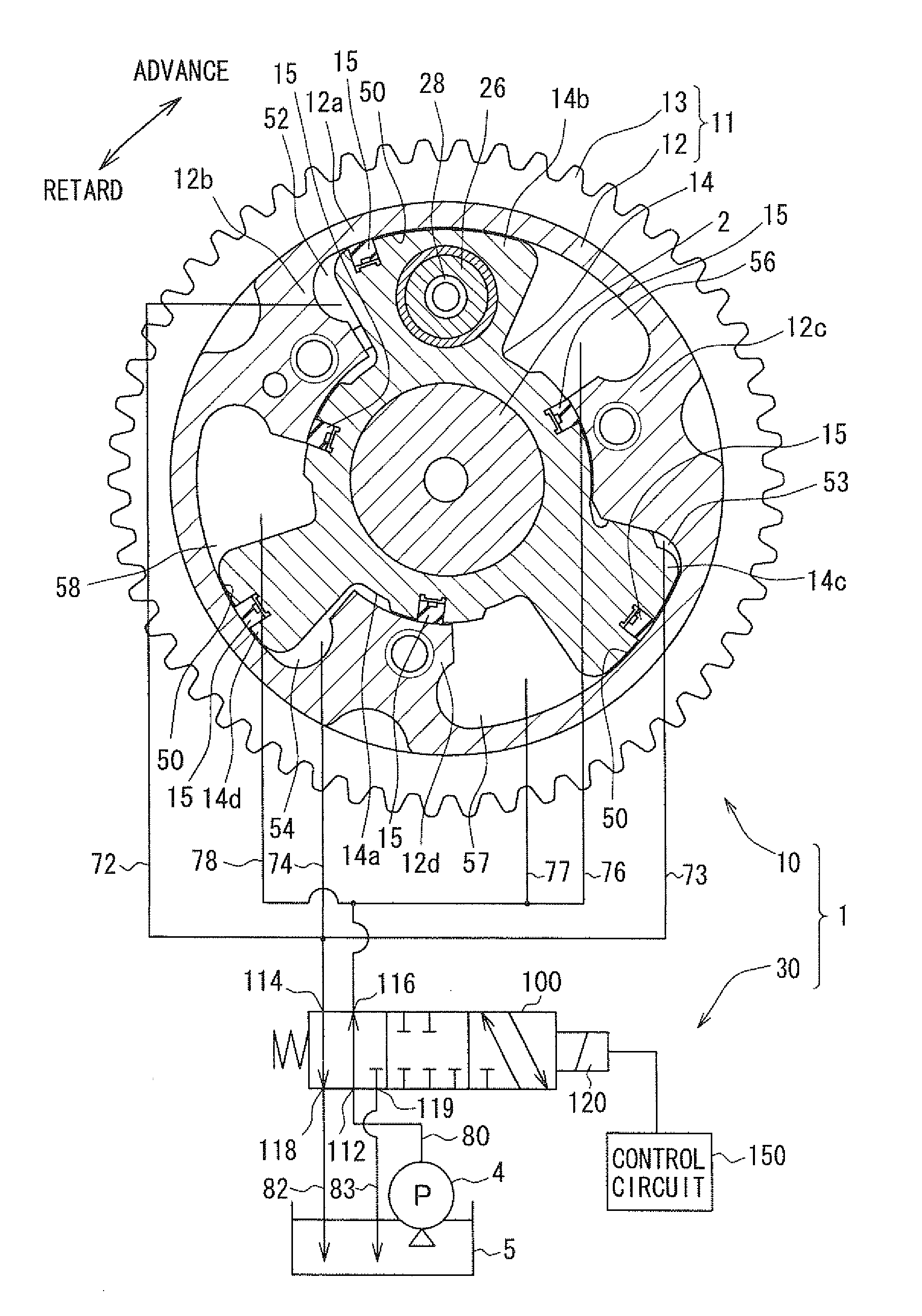

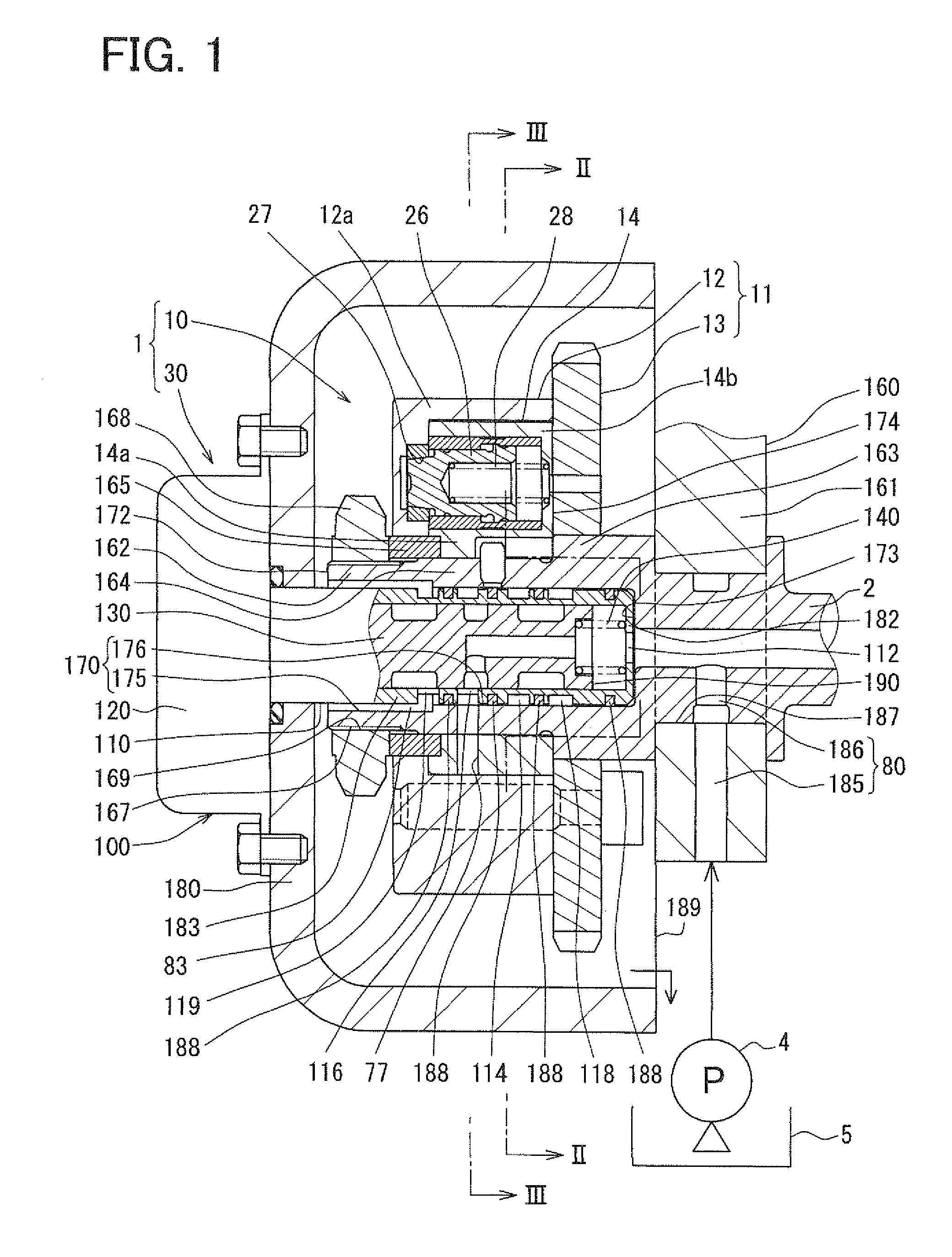

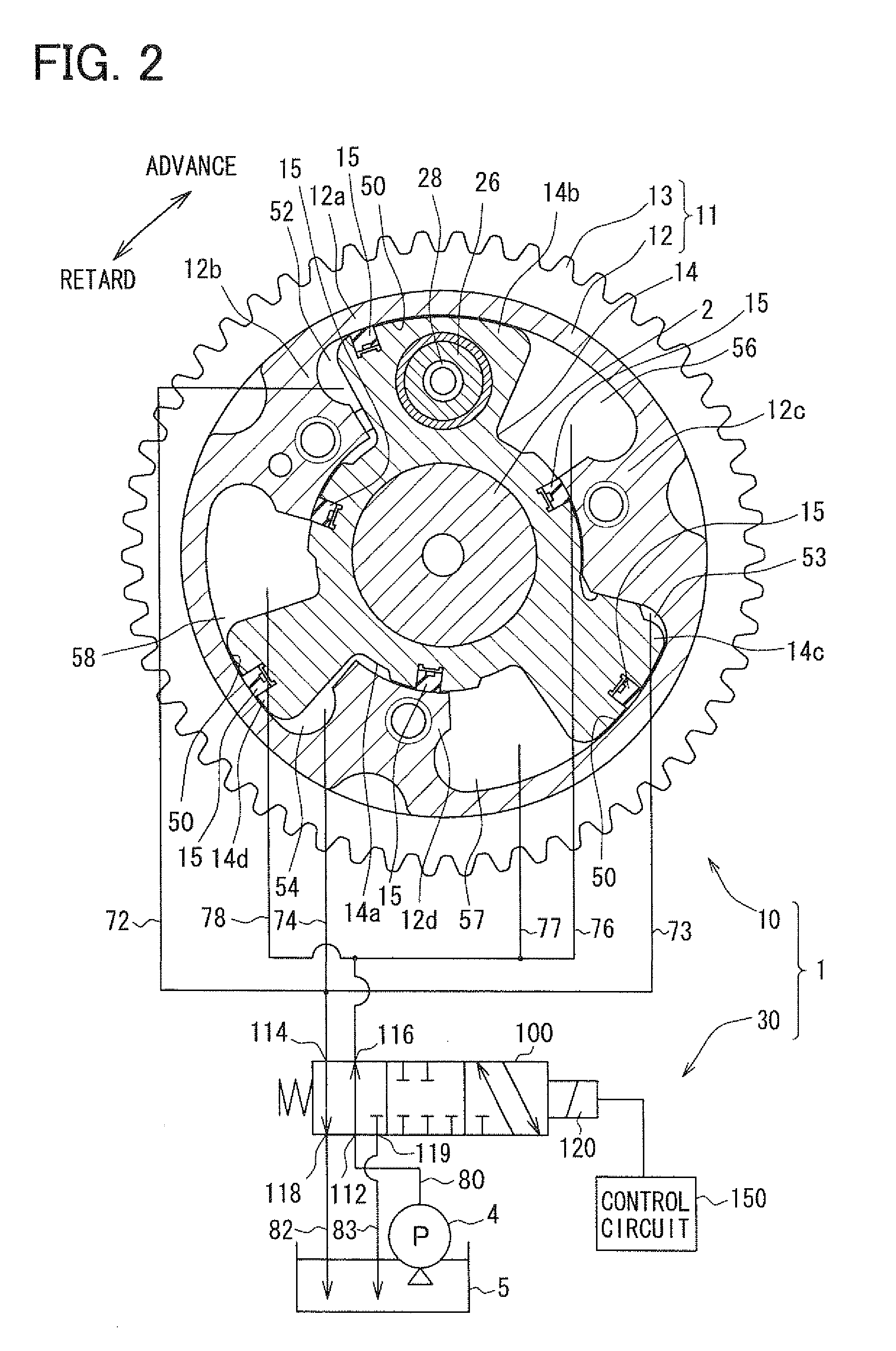

[0024]FIGS. 1, 2, 9 show examples, in which a valve timing adjusting apparatus 1 of the first embodiment of the present invention is applied to an internal combustion engine of a vehicle. The valve timing adjusting apparatus 1 is a fluid operated apparatus that employs hydraulic oil serving as “working fluid”, and is capable of adjusting valve timing of an intake valve that serves as a “valve”.

(Basic Configuration)

[0025]A basic configuration of the present embodiment will be described. The valve timing adjusting apparatus 1 includes a drive unit 10 and a control unit 30. The drive unit 10 is provided in a driving force transmission system and is driven by hydraulic oil. The driving force transmission system transmits a driving force of a crankshaft (not shown) of an internal combustion engine to a camshaft 2 of the internal combustion engine. The control unit 30 controls supply of hydraulic oil to the drive unit 10.

(Drive Portion)

[0026]The drive unit 10 includes a housing 11 and a v...

second embodiment

[0085]As shown in FIG. 10, the second embodiment of the present invention is a modification of the first embodiment. The second embodiment is characterized in that a check valve 200 is provided in the inner passage 197 of the spool 130.

[0086]Specifically, the check valve 200 includes a valve seat 202, a valve member 204 and a biasing member 206. The valve seat 202 is a radially inner surface formed on an intermediate position of the inner passage 197, and an inner diameter of the valve seat 202 is reduced toward the input port 112 to have a conic surface. The valve member 204 is made of a metal to have a bulbous shape, and is provided in the inner passage 197 on an opposite side of the valve seat 202 opposite from the input port 112. Thus, the valve member 204 is able to be displaceable in the longitudinal direction so that the valve member 204 is positioned away from and is seated on the valve seat 202. The biasing member 206 is made of a metallic compression coil spring, and is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com