Vertical filling-packaging machine

a filling machine and vertical technology, applied in the direction of transportation packaging, packaging, feeding apparatus of wrapping materials, etc., can solve the problems of difficult mixing of air bubbles or the like into the content material, and achieve the effect of reducing the amount of content material and good quantitative accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

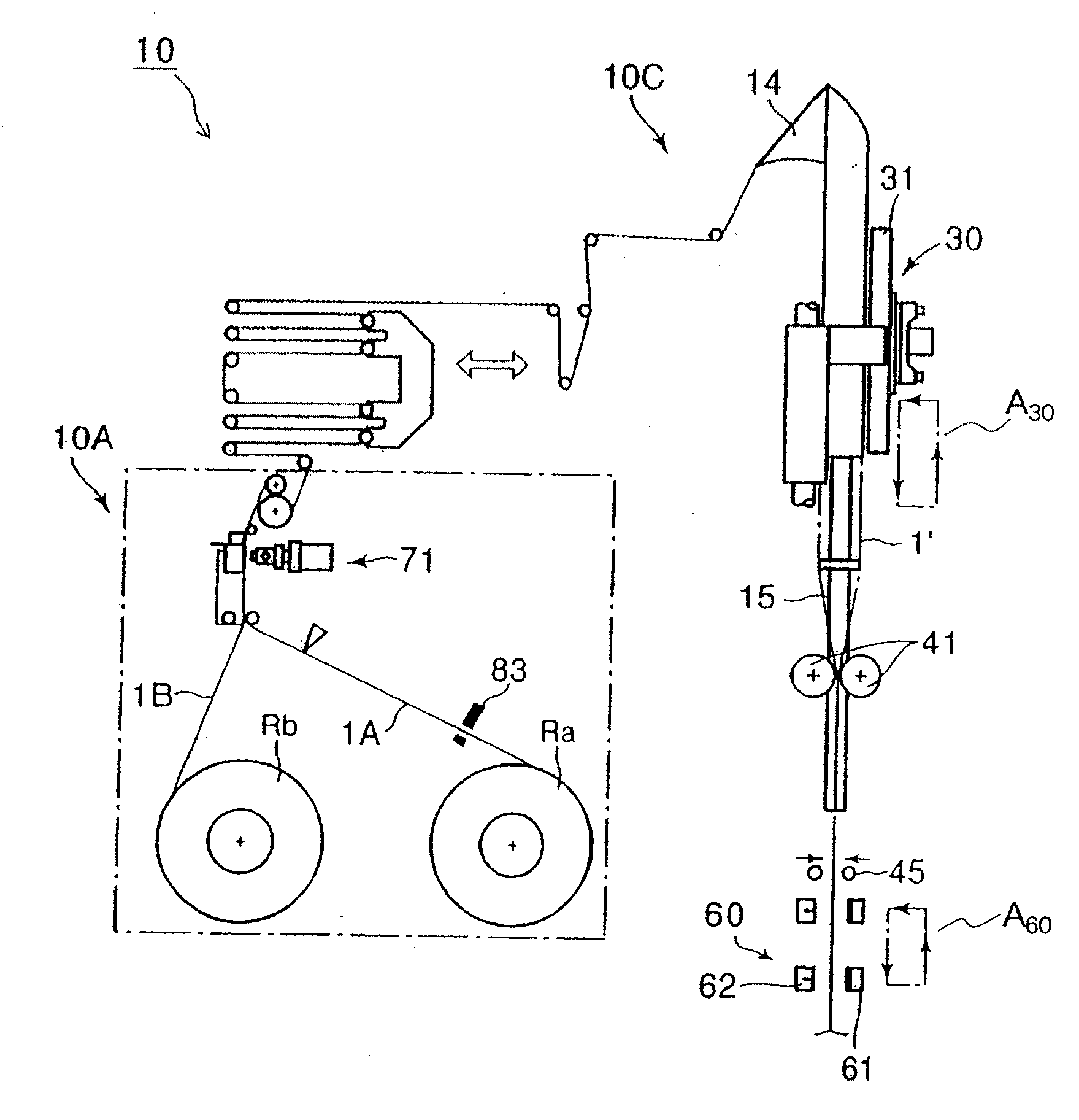

[0066]As shown in FIG. 3, packaging machine 10 of the present embodiment includes film feeding mechanism 10A that draws a film from feed rolls Ra and Rb, and joins film 1A and film 1B as needed. Further, packaging machine 10 includes packaging mechanism 10C that forms the film unrolled from film feeding mechanism 10A into a tubular shape, and that continuously manufactures a packaging bag by forming a vertical sealed portion and a lateral sealed portion thereon as needed.

[0067]As film feeding mechanism 10A, a proposed film feeding mechanism, which includes a general configuration for such a packaging machine, can be used. Film feeding mechanism 10A shown in FIG. 3 uses two feed rolls Ra and Rb, and is configured such that, for example, when film 1A of feed roll Ra has been used up, film 1B of feed roll Rb is continuously unrolled. It should be noted that FIG. 3 shows that film 1A is drawn into a side of the packaging mechanism 10C as a film on the using side, and that film 1B is hel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com