Vacuum cleaner

a vacuum cleaner and vacuum technology, applied in the field of vacuum cleaners, can solve the problems of high counter-voltage, and achieve the effect of effective filter cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

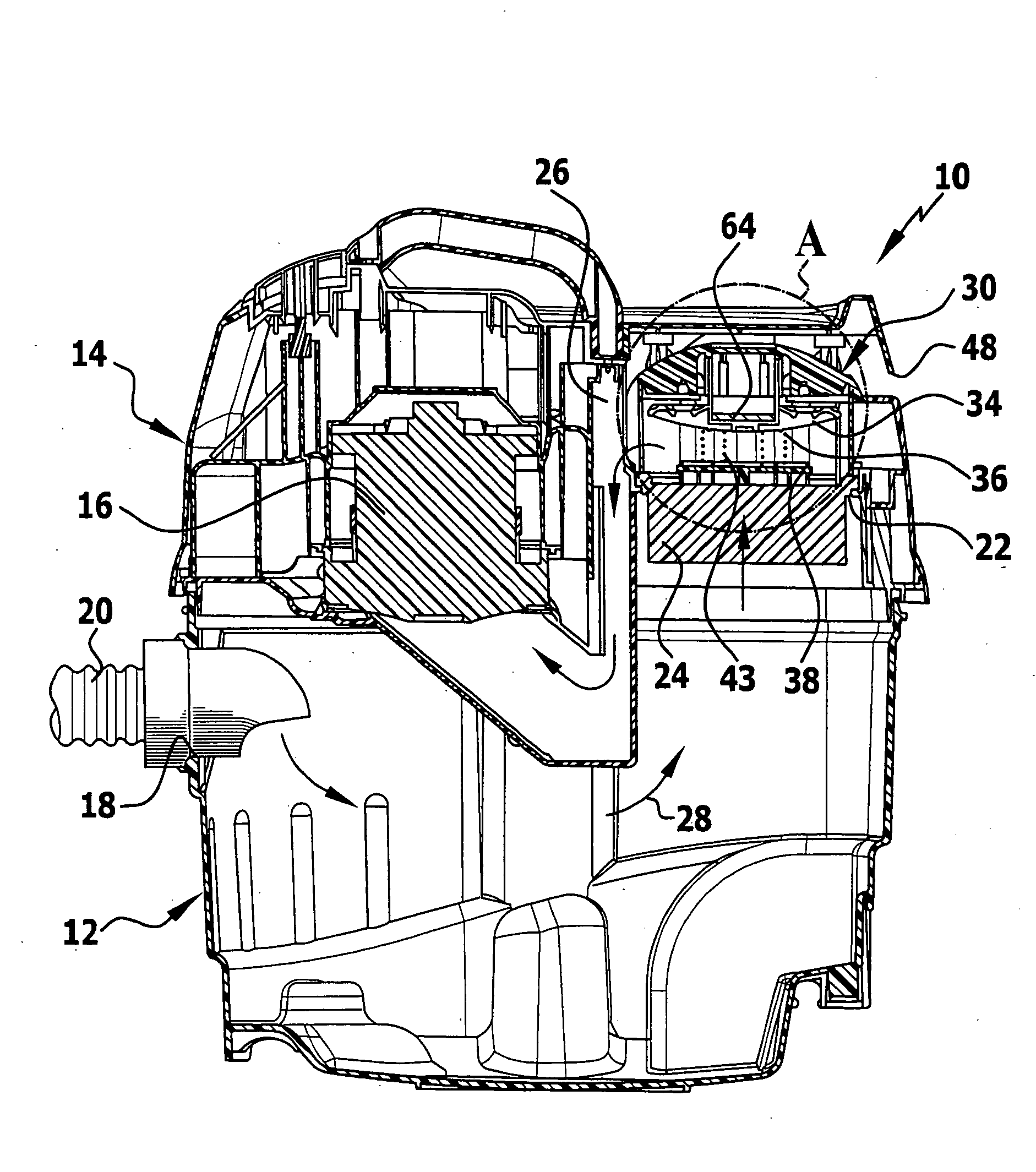

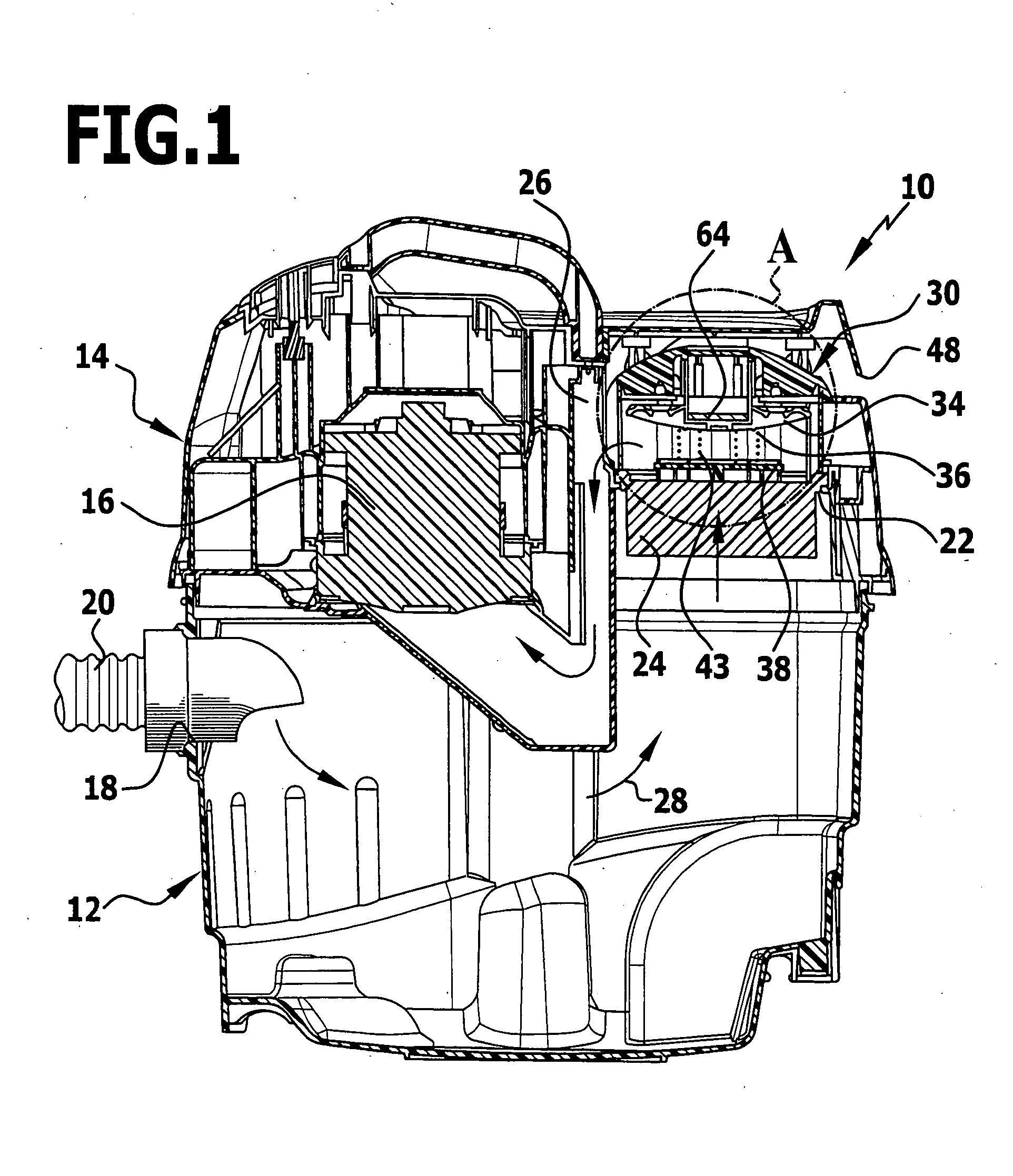

[0039]In the drawings, a vacuum cleaner 10 is illustrated schematically with a lower part which forms a dirt collection tank 12 and with an upper part 14 which is placed on the lower part and accommodates a suction unit 16. The dirt collection tank 12 comprises a suction inlet 18, to which a suction hose 20 can be connected. A suction nozzle can be connected to the free end of the suction hose 20 which is not illustrated in the drawings in order to achieve a better overview. Alternatively, it may be provided for the suction hose 20 to be connected to a machining tool, for example, a drilling unit or a milling unit so that dust which occurs during operation of the machining tool can be sucked in.

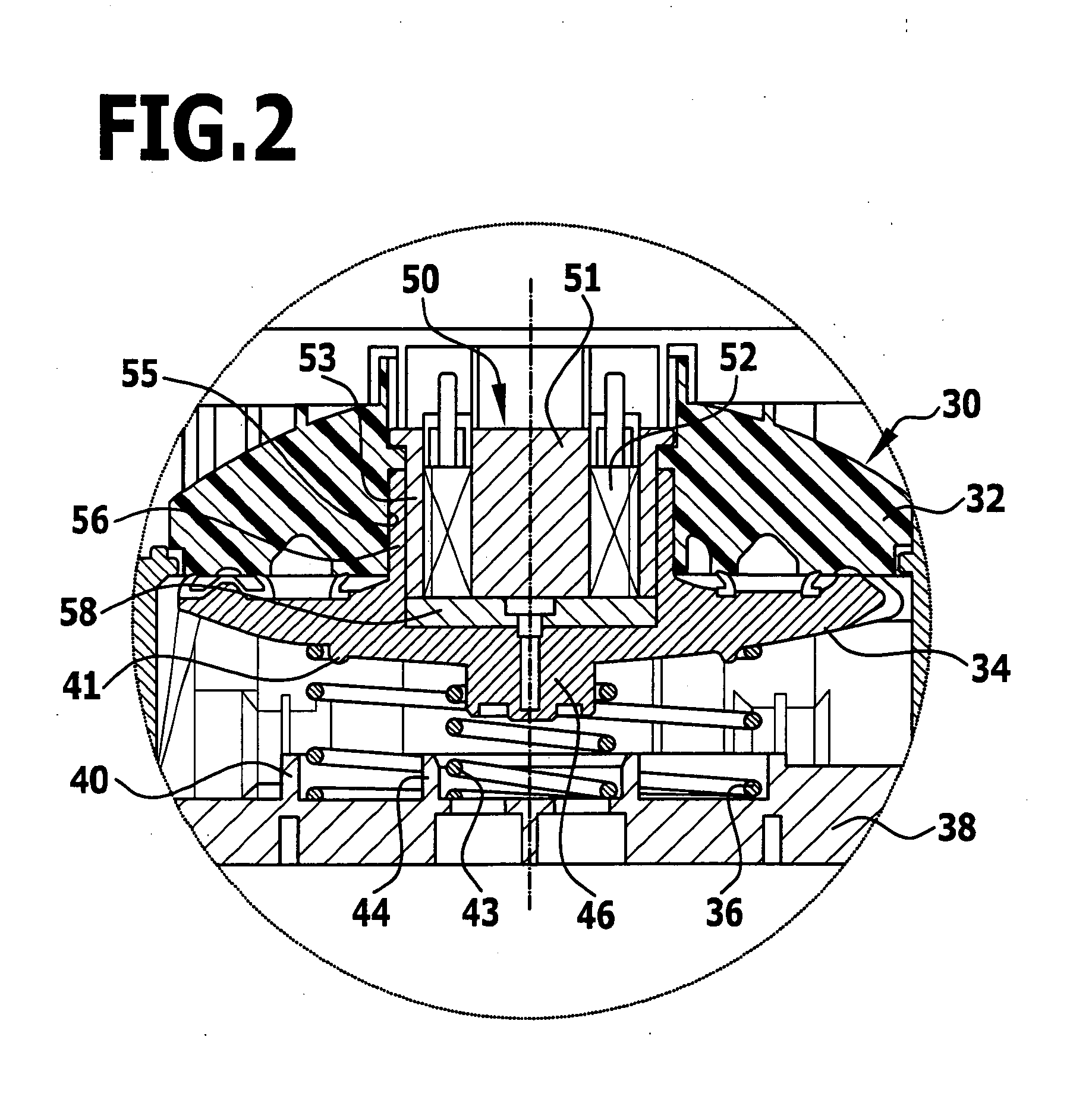

[0040]The upper part 14 forms a suction outlet 22 for the dirt collection tank 12. A folded filter 24 is held on the suction outlet 22 and an extraction line in the form of a suction channel 26 is connected to the filter. The folded filter 24 is permanently in flow connection with the suction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com