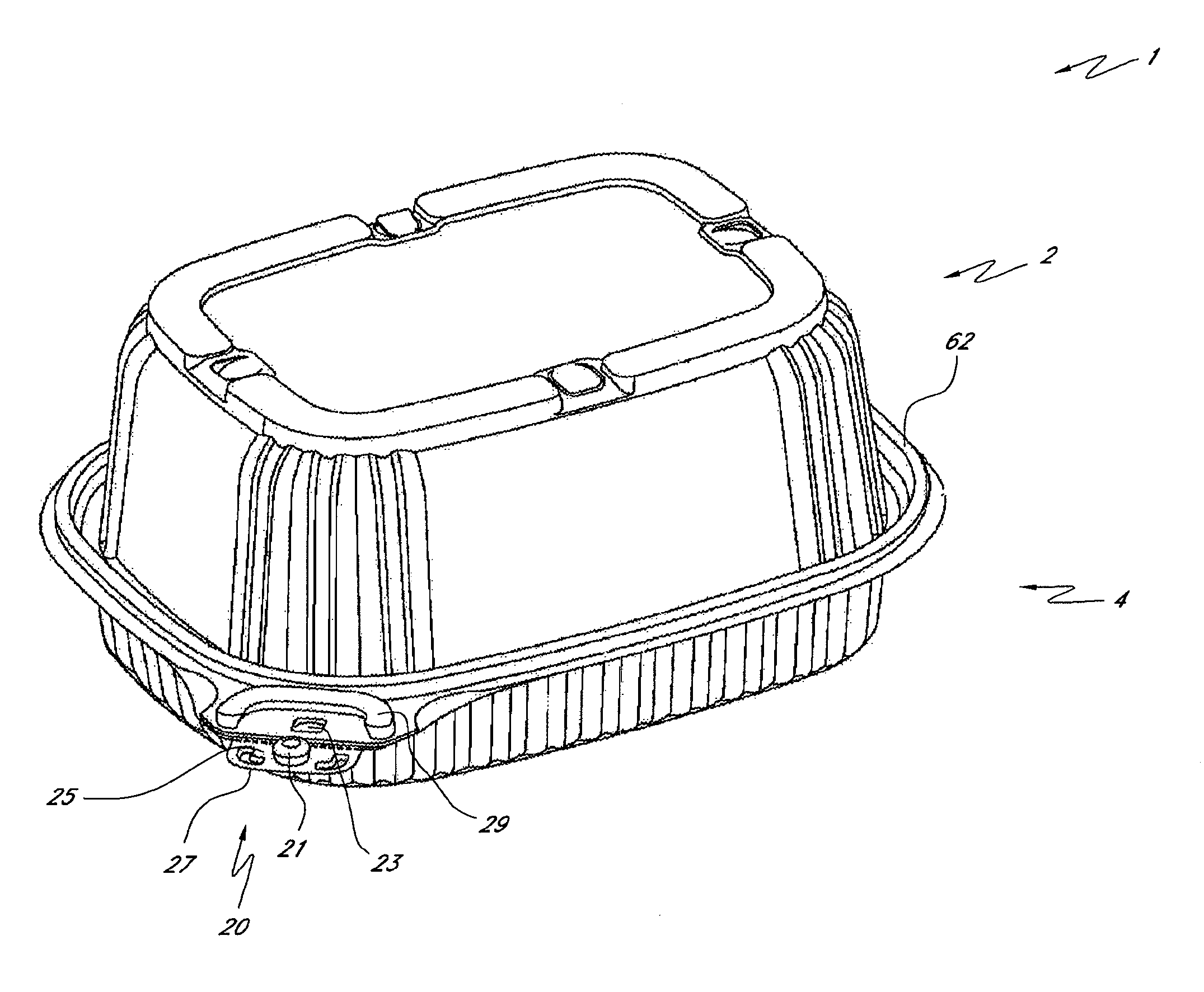

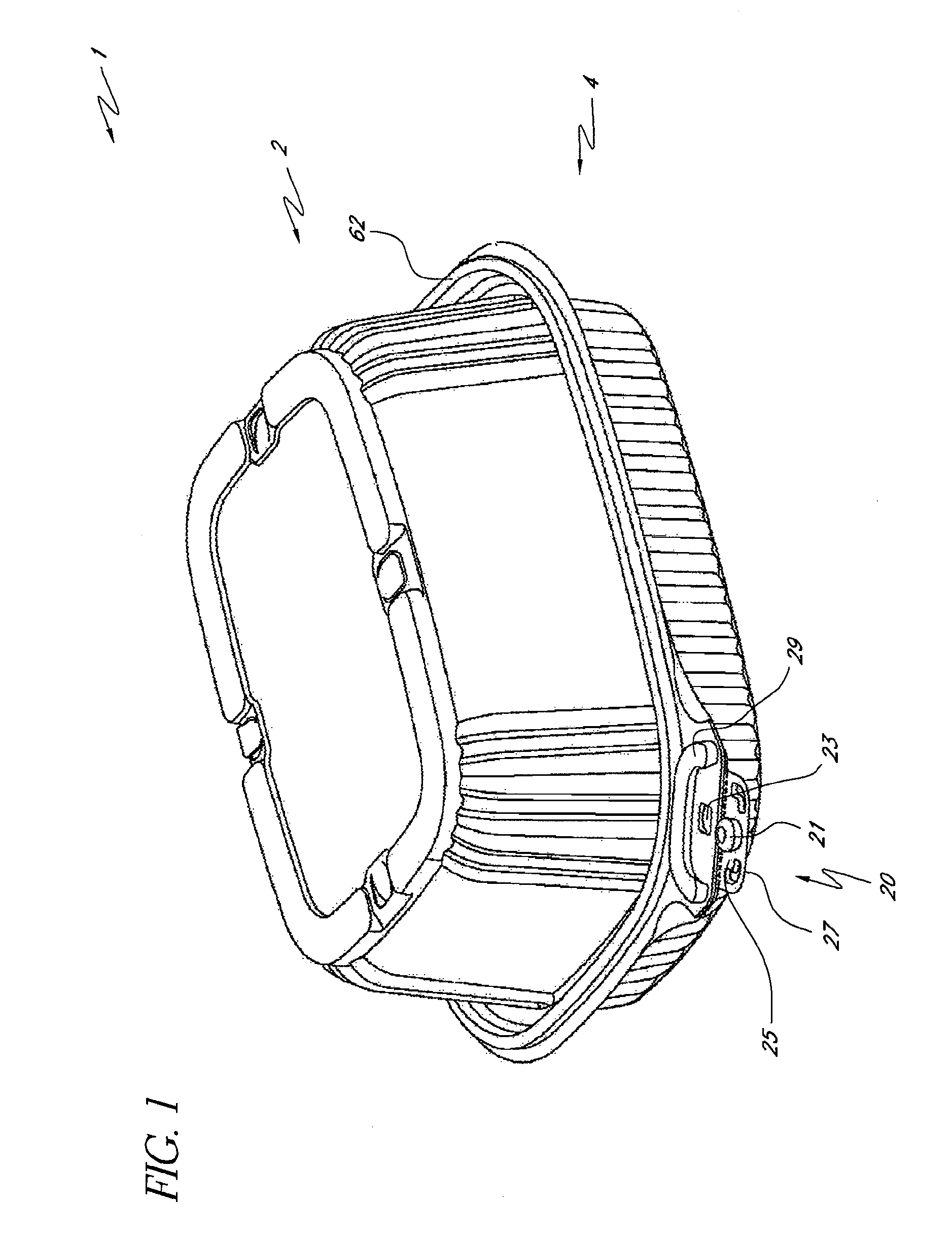

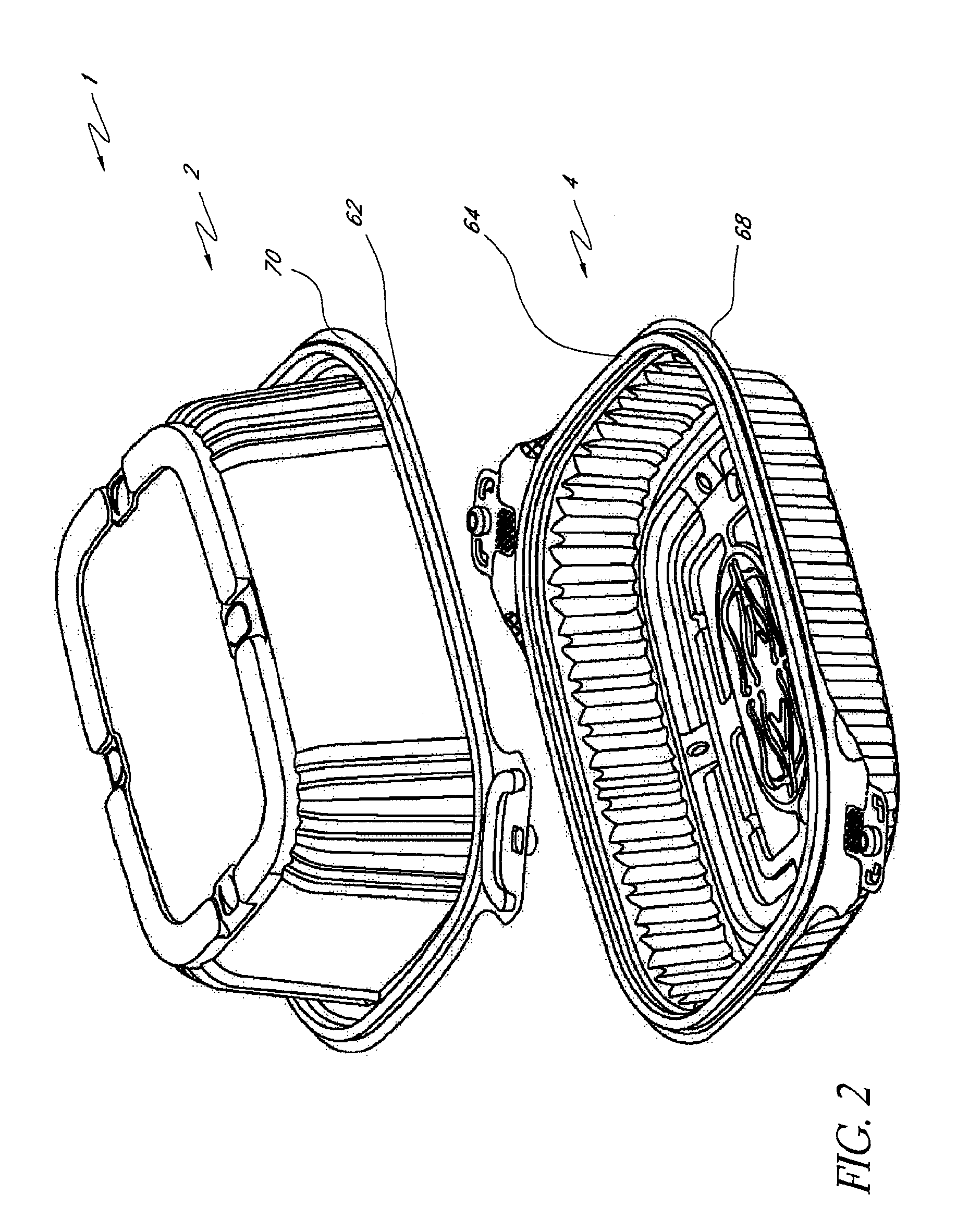

Tamper-evident packaging system

a packaging system and packaging technology, applied in the field of container systems, can solve the problems of affecting the convenience of carrying, releasing heated gases, and a large number of chicken roaster packages without a means by which consumers can know whether the packaging has been tampered with,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]Rigid and flexible plastic containers can be used to protect and display both perishable and fragile food items such as sandwiches, salads and bakery items. The roles of plastic packaging can be expanded to meet additional demands. Presentation, brand presence, consumer desires, added value to enhance commercial competitiveness, differentiation, imagery and psychology can all be factors in package design and application. Convenience and versatility continue to shape the future of packaging, with consumers gravitating toward packaged convenience items. Thus, social and environmental considerations can be advantageously included in the development process of plastic packaging. The provision of multiple compartments in a variety of shapes and utilities in rigid plastic containers is an example of a useful advantage.

[0039]Plastic food containers can be manufactured, for example, from Polystyrene, Polypropylene, Polyethylene Terephthalate (PET), Polylactide, Polyvinyl Chloride (PVC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com