Demand driven ice mode software

a technology of demand driven ice mode and software, which is applied in the field of automatic boosting of ice production, can solve the problems of ice production not being produced, danger of running out, and already reduced supply of ice, and achieve the effect of increasing ice production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

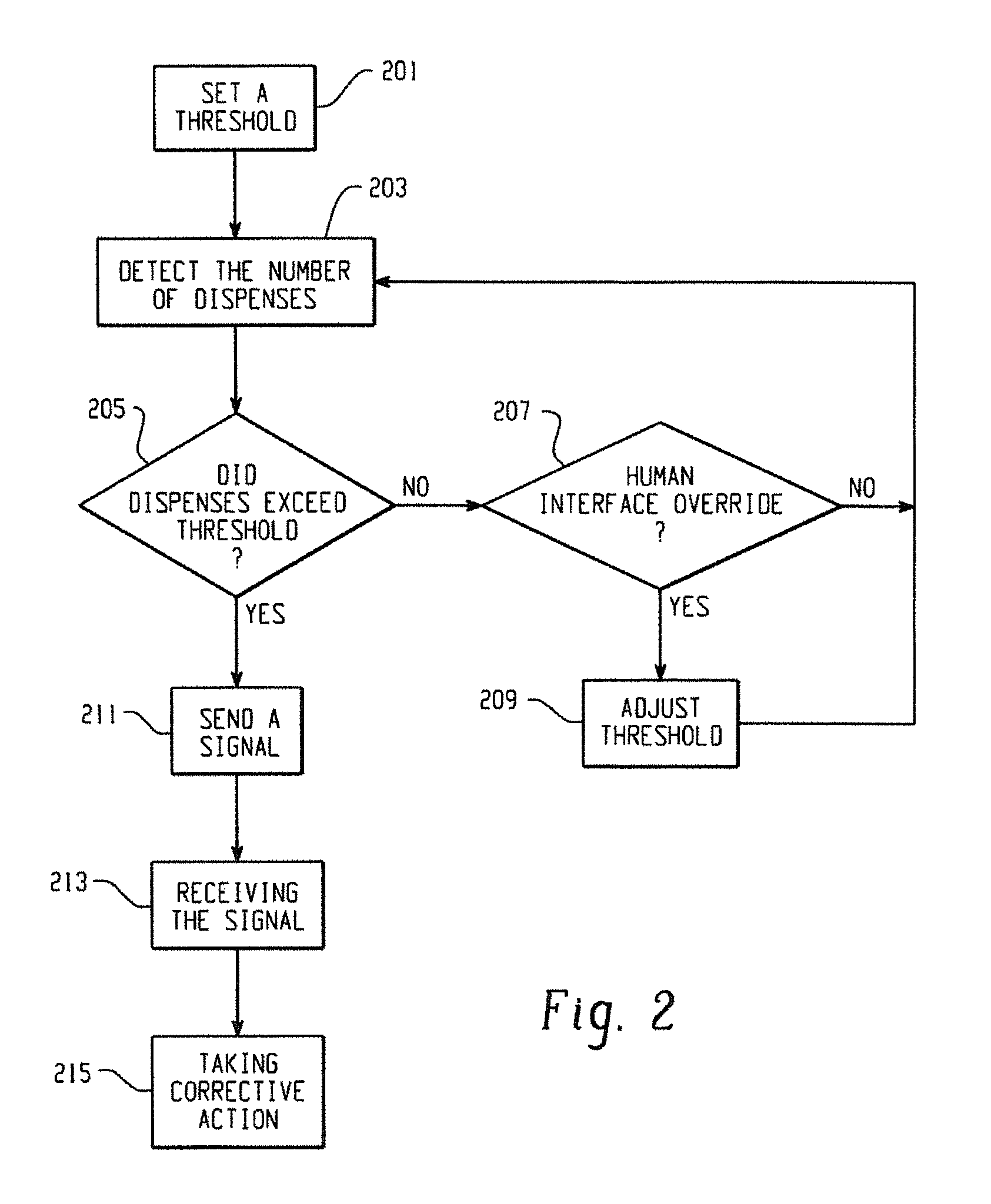

[0012]This disclosure is related to software that responds to consumer usage patterns in order to create more ice. This developed software monitors ice dispenses and takes corrective action when a threshold of dispenses is surpassed within a predetermined period of time. The corrective action may include the freezer running colder for a preset period of time which in turn will active an evaporator fan which lowers the temperature and increases convection across the ice maker. For example, the freezer which is generally set by the controller may run at 2 set points colder for 24 hours. This colder freezer setting will allow the ice maker to make more ice, replenishing the supply faster.

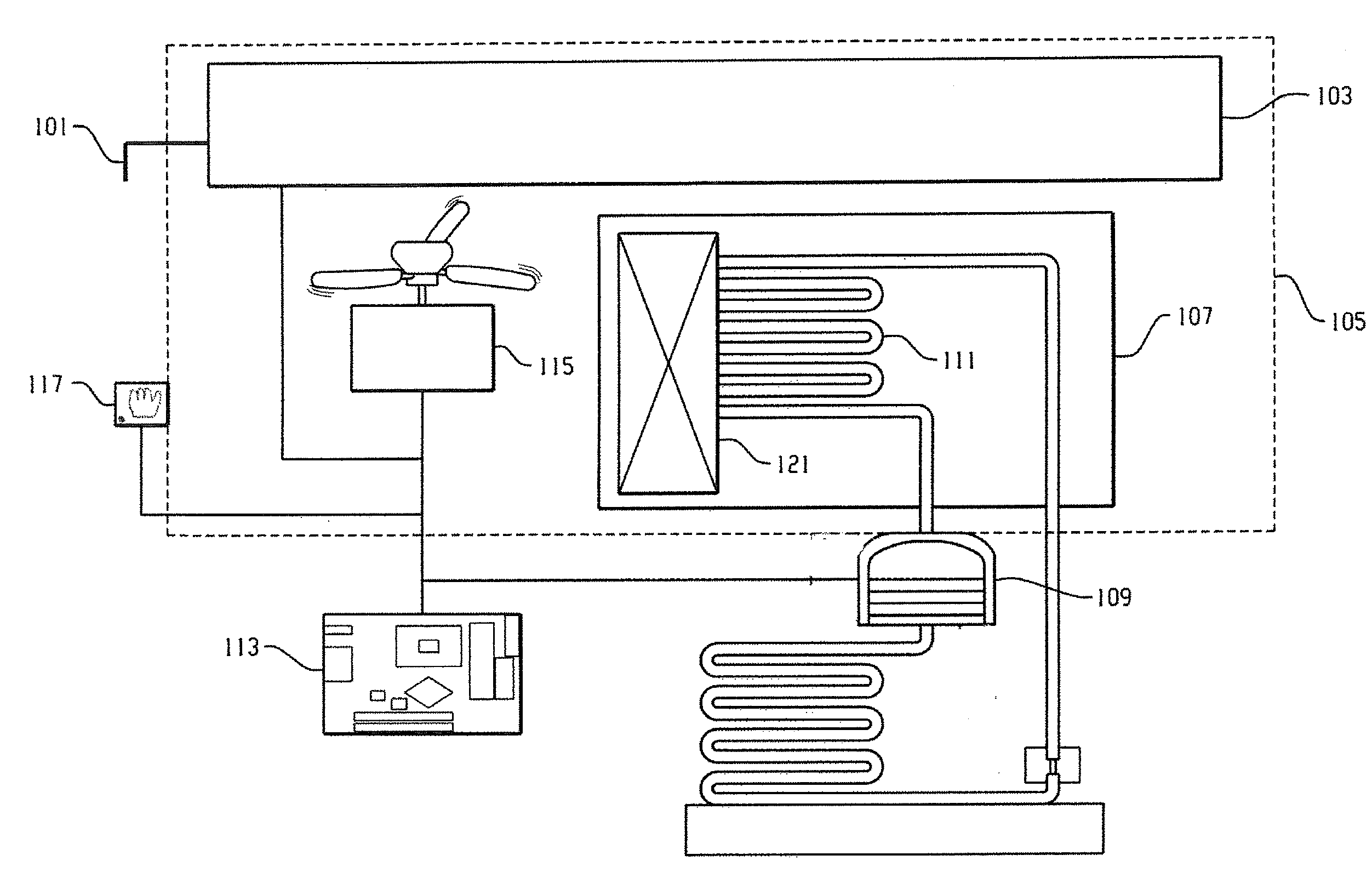

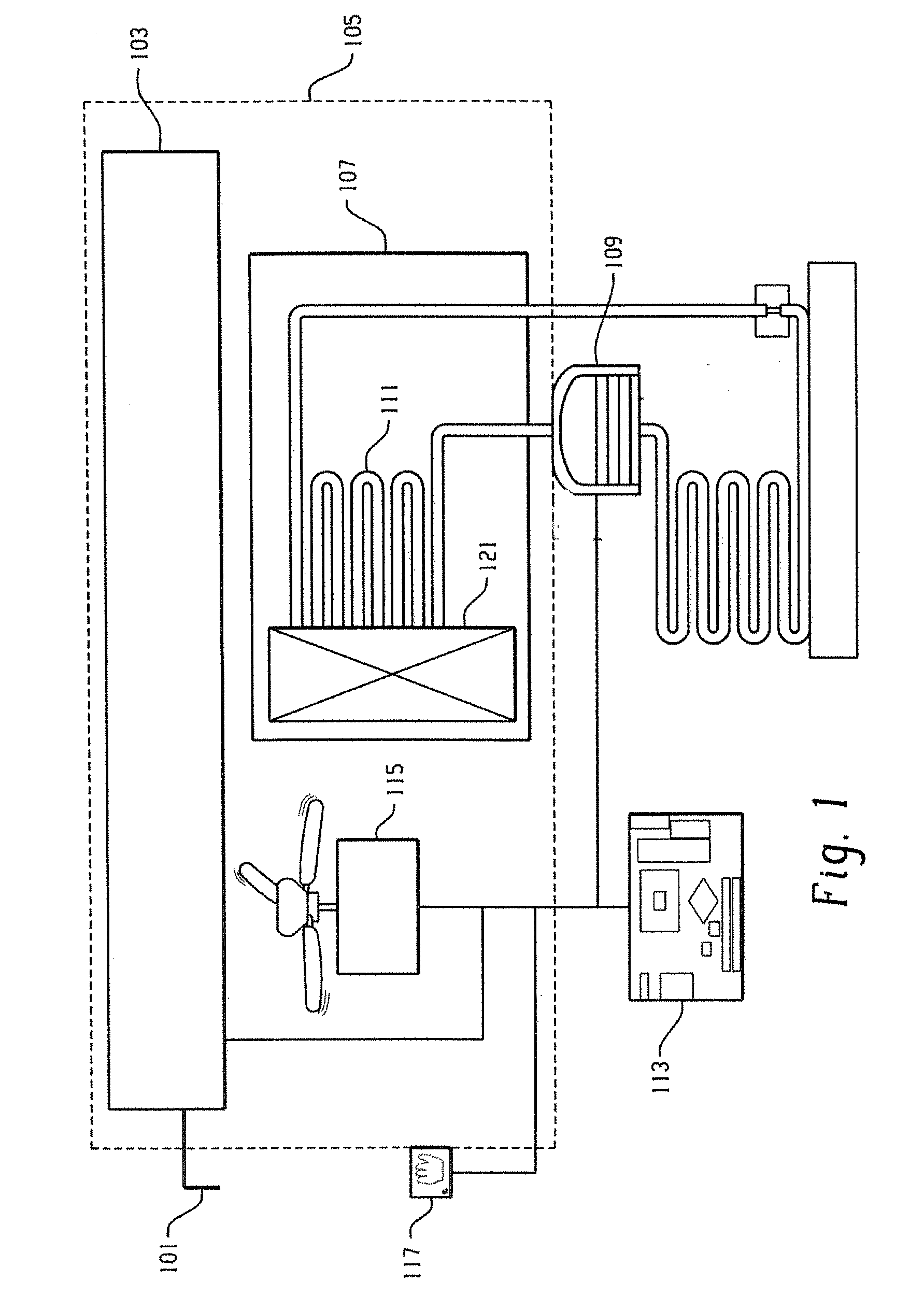

[0013]Shown in FIG. 1 is a representation of a freezer with an ice maker. As shown, FIG. 1 includes a trigger 101, which is connected to an ice maker 103. The ice maker is situated inside a freezer region 105 and the freezer region is kept frozen by the freezer cycle 107. The freezer cycle includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com