Joint assembly with centering flange

a technology of centering flange and joint assembly, which is applied in the direction of couplings, manufacturing tools, mechanical devices, etc., can solve the problems of requiring precision fit and easy binding, and achieve the effect of minimizing the force necessary and increasing the tolerance between the centering flange and the second rotating par

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

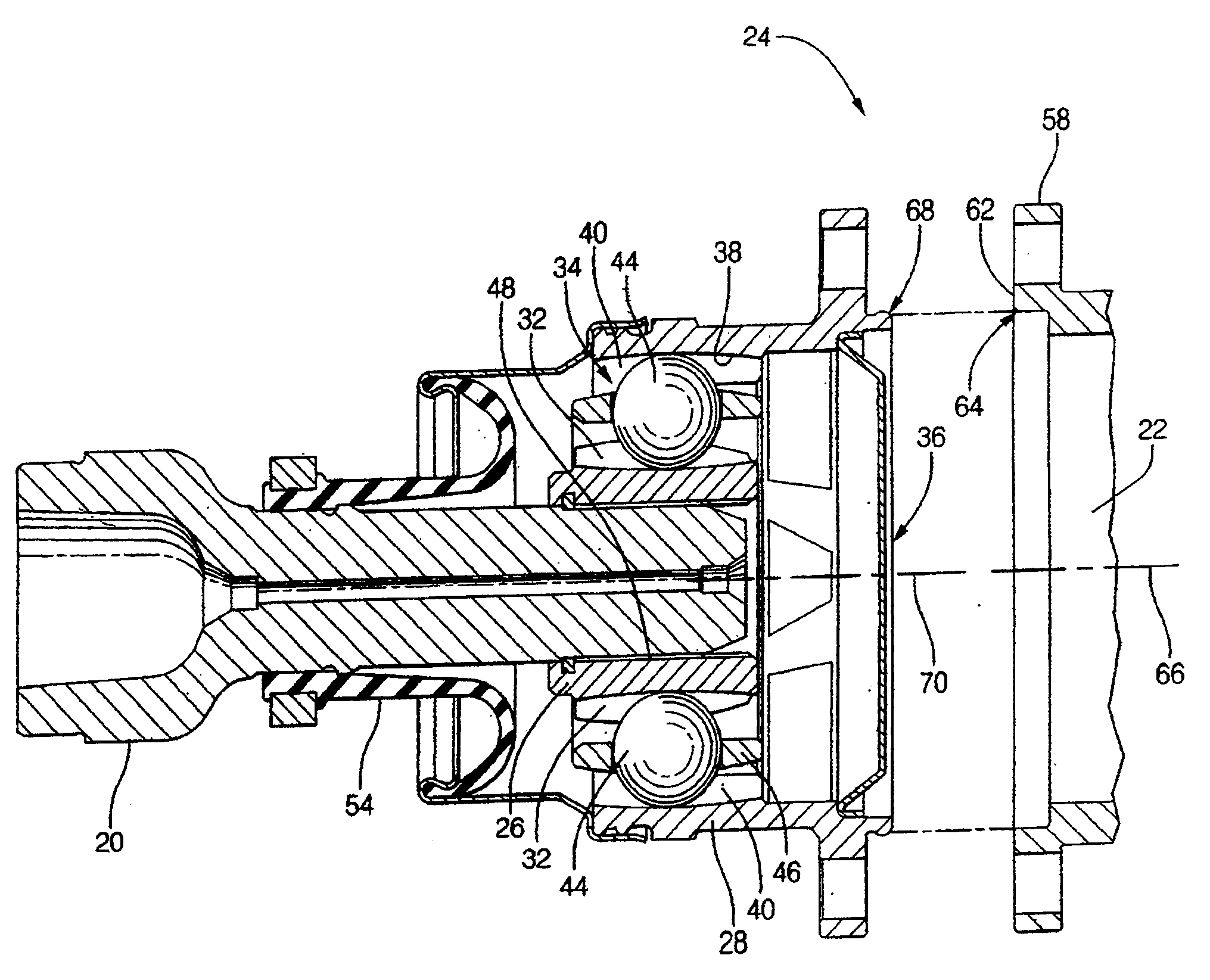

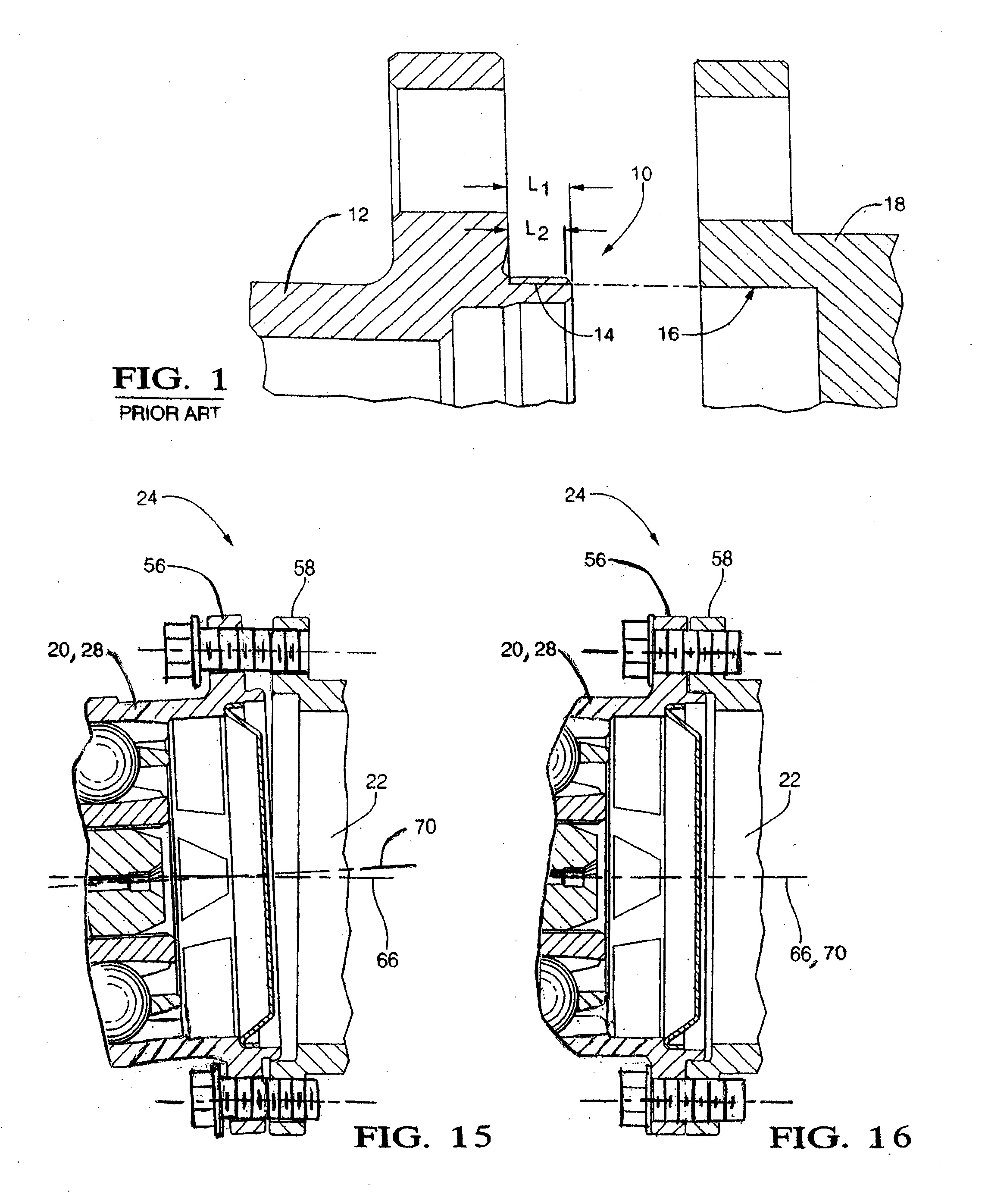

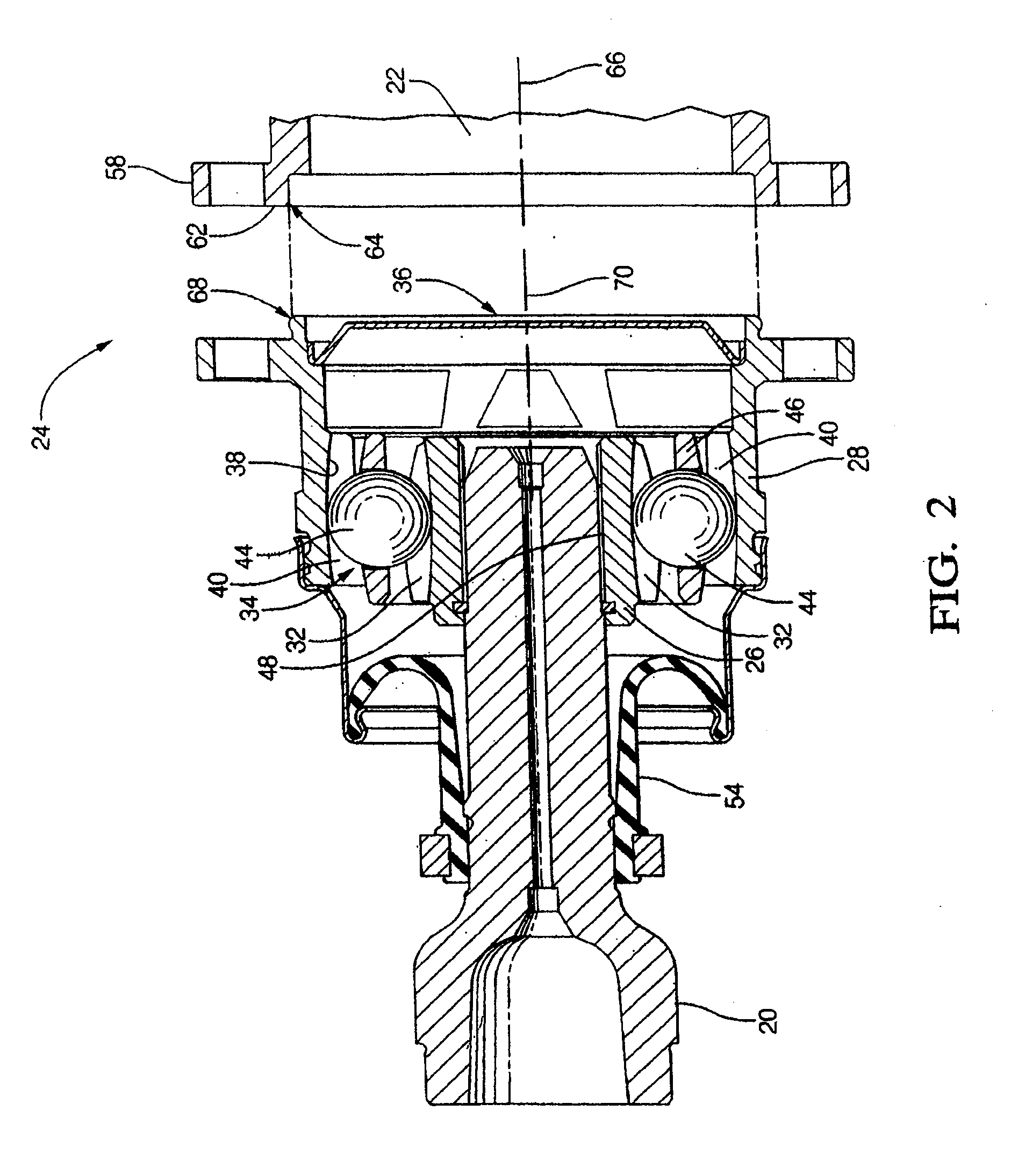

[0017]Referring to the Figures, wherein like numerals indicate like or corresponding parts throughout the several views, a joint assembly for coupling first 20 and second 22 rotating parts is shown generally at 24. In one embodiment, the first rotating part 20 is described as including a constant velocity or CV joint. However, the joint assembly 24 may be any joint assembly capable of operatively coupling parts for rotation, while allowing the parts to deviate from perfect axial alignment with one another.

[0018]Referring to FIGS. 2-3, the first rotating part 20 includes a CV joint having a first CV joint member 26, known as an inner race in some embodiments and a second CV joint member 28, known as an outer race in some embodiments, that is mounted to the second rotating part 22, thereby forming joint assembly 24. As is typical of known CV joints, the first CV joint member 26 is formed with an outer curved surface 30 (see FIG. 3) in which a plurality of first ball grooves 32 are for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com