Zipper head

a zipper head and zipper technology, applied in the direction of snap fasteners, slide fasteners, press-button fasteners, etc., to achieve the effect of reducing costs and flexible choi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

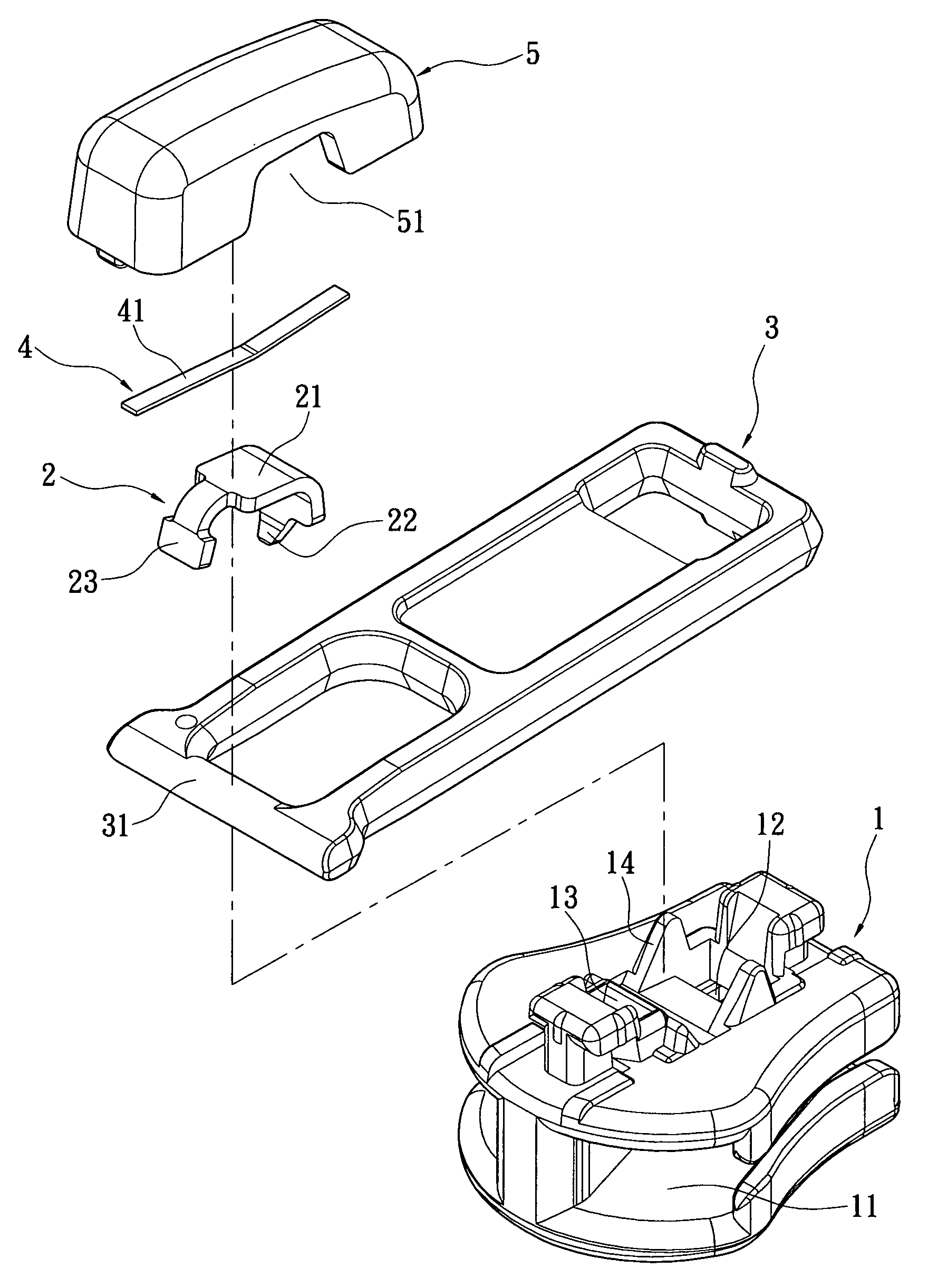

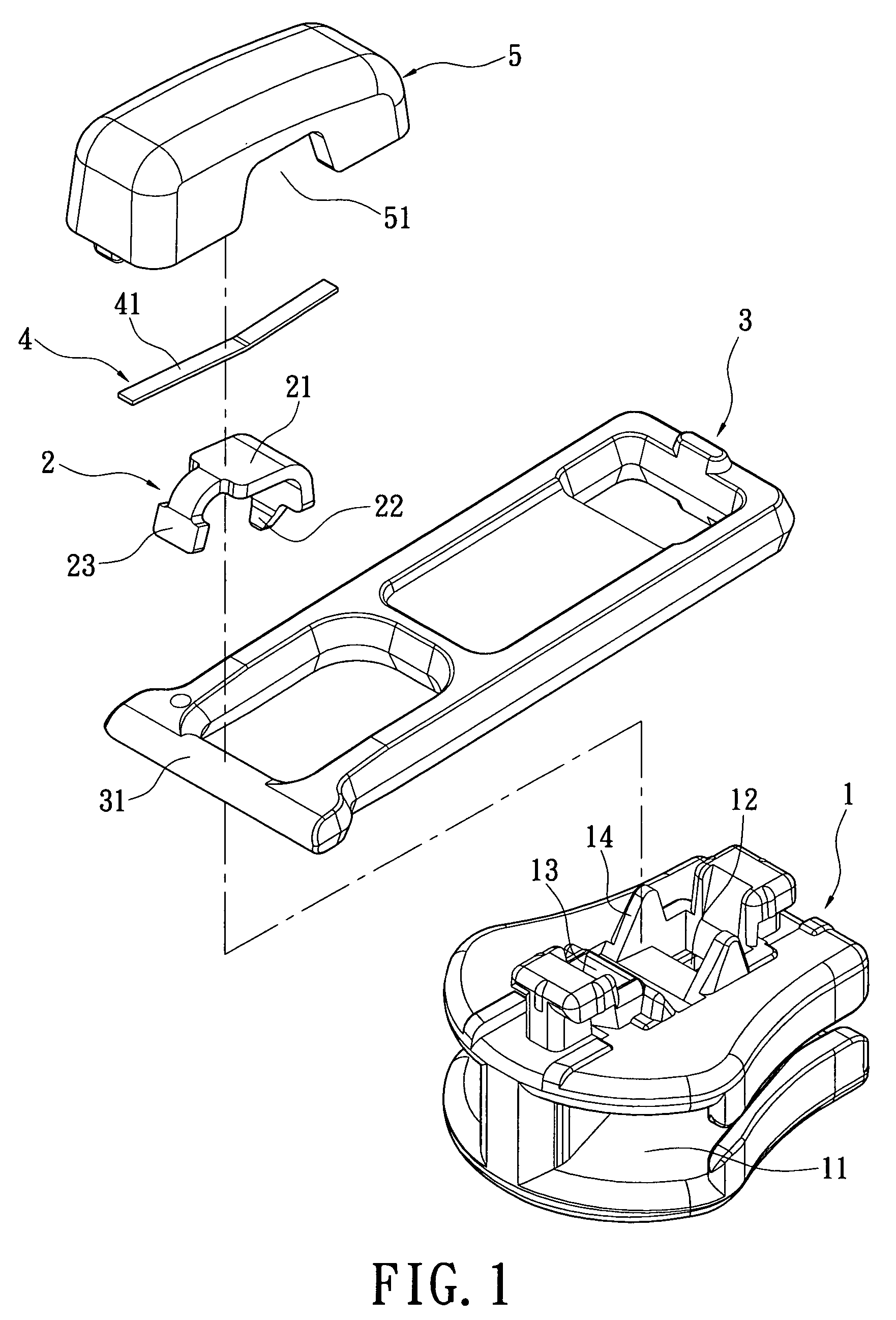

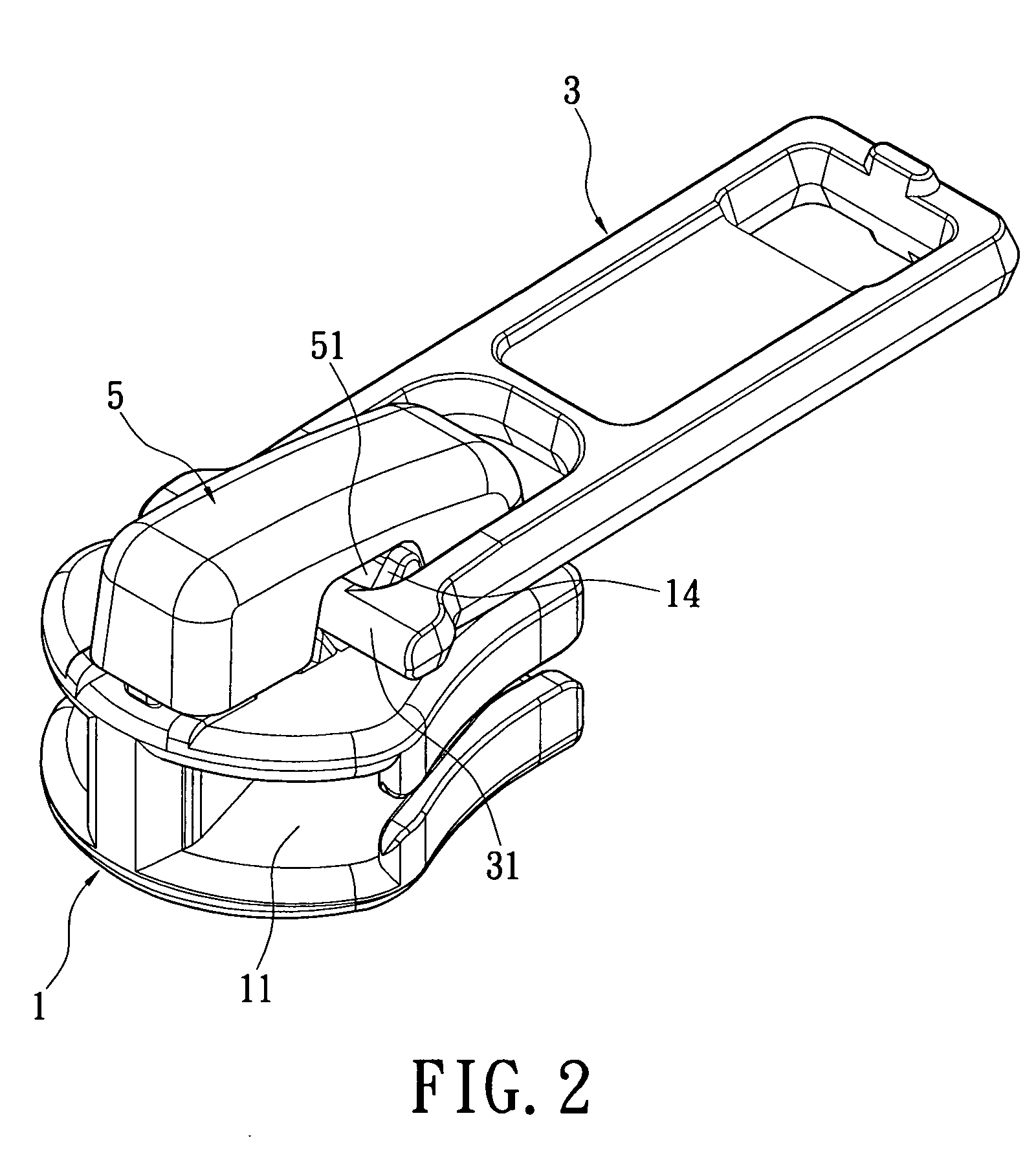

[0019]Please refer to FIGS. 1 to 4. The present invention is to provide an improved zipper head including a puller 1, a hook 2, a pulling piece 3, an elastic piece 4 and a cap 5.

[0020]The interior of the puller 1 forms guiding grooves 11 for allowing a zipper (not shown) to be fitted therein. The top of the puller 1 has a through hole 12 and a positioning hole 13. The through hole 12 is in communication with the guiding grooves 11, and the positioning hole 13 is recessed on the top of the puller 1. Moreover, both sides of the through hole 12 each have a blocking portion 14 protruded from the puller 1.

[0021]The hook 2 has a straight-shaped main portion 21, a hook portion 22 and a fulcrum portion 23. The hook portion 22 is bent and extends downwards from one end of the main portion 21, and the fulcrum portion 23 is bent and extends downwards from another end of the main portion 21.

[0022]The pulling piece 3 has a sheet body, and its shape can be changed according to the requirements of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap