Hydraulic well packer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

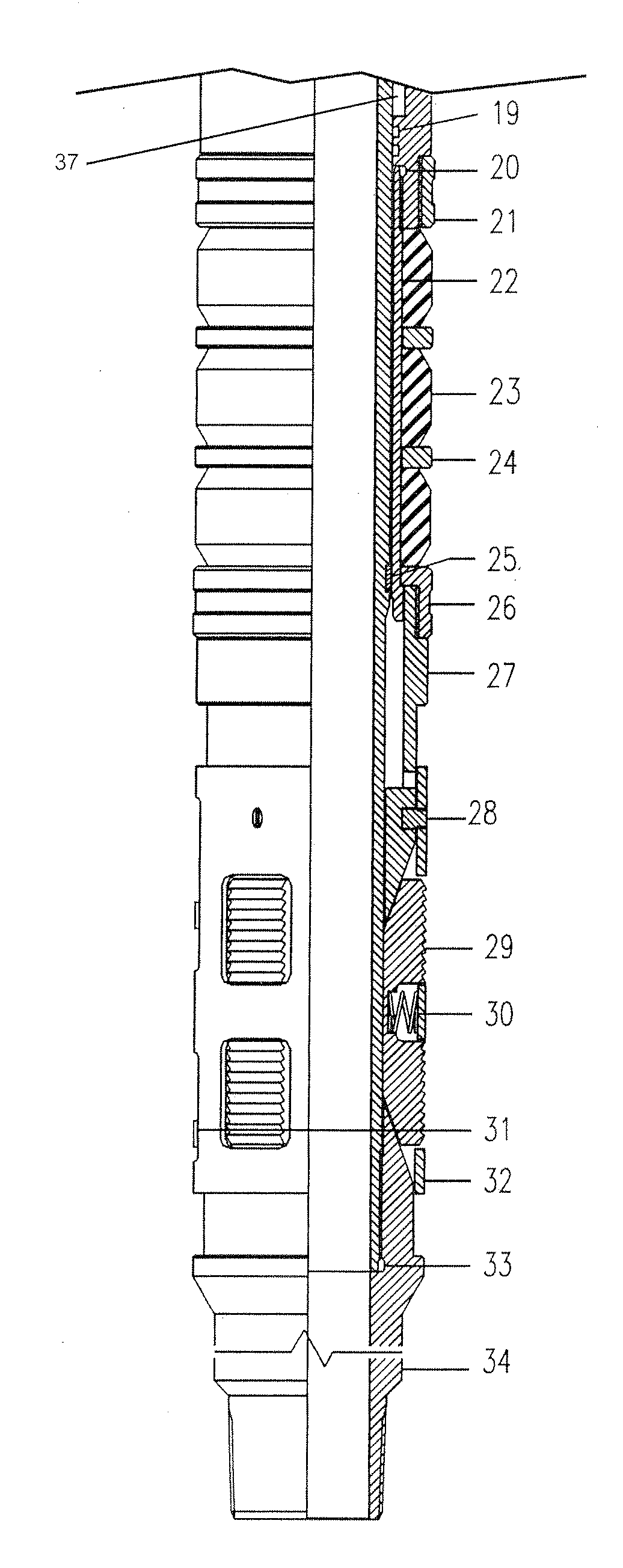

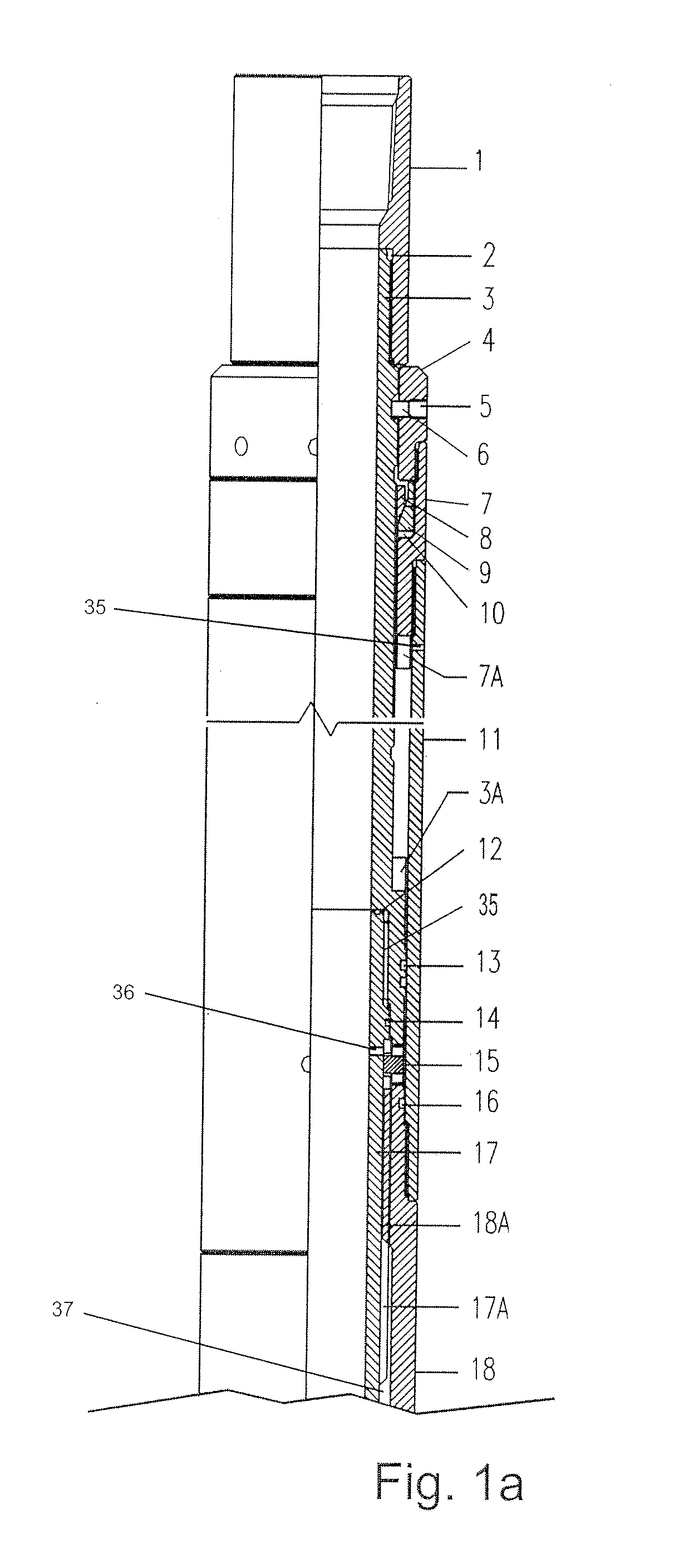

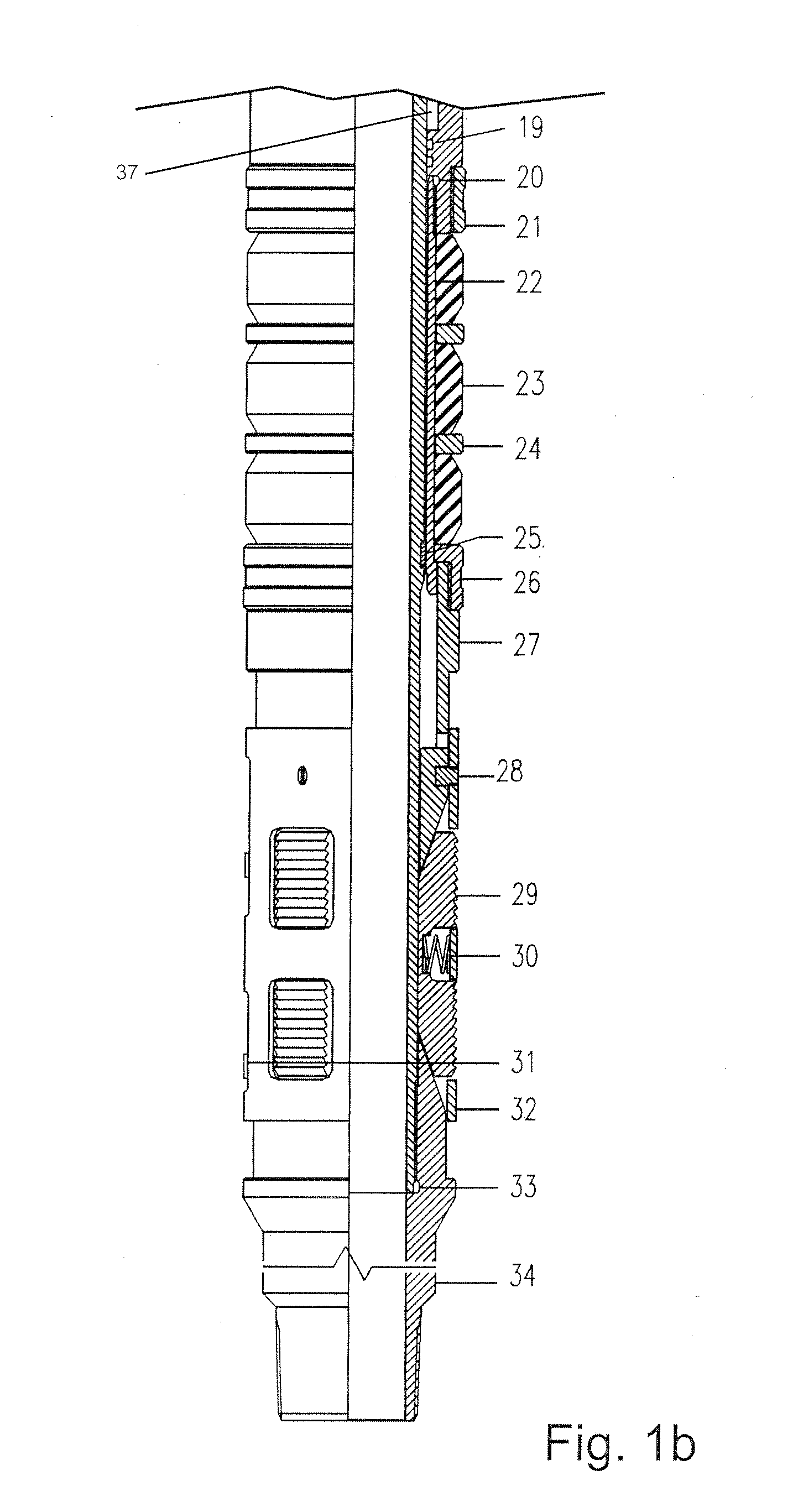

[0030]Describing the exemplifying device of the present invention and making reference to the Figure, it can be observed that the retrievable hydraulic packer with double latch comprises a tool to be applied when it is necessary to isolate or seal temporarily or permanently the well area, with the possibility to carry out different operations, specially used on selective installations, such as oil, water or gas wells, or wells of different fluids.

[0031]The packer of the present invention comprises, in the upper end, an upper header 1, that may have a male or female thread, where there is a mandrel threaded, which according to the invention, is a split mandrel formed by an upper mandrel 3 and a lower mandrel 17. Mandrel 3 is isolated by seal 2 and over upper mandrel 2 there is a compression safety assembly formed by pin 4 that houses in its periphery a plurality of safety shear pins 4 and the screw 5 that is used to retain and press the shear pins 6 against the notches of the upper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com