Slip resistant collar stay

a collar stay and slip-resistant technology, applied in collars, clothing, applications, etc., can solve the problems of collar stays that have been known to slip completely out of the pocket, and achieve the effect of reducing the friction coefficient, eliminating or minimizing the movement of the collar stay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

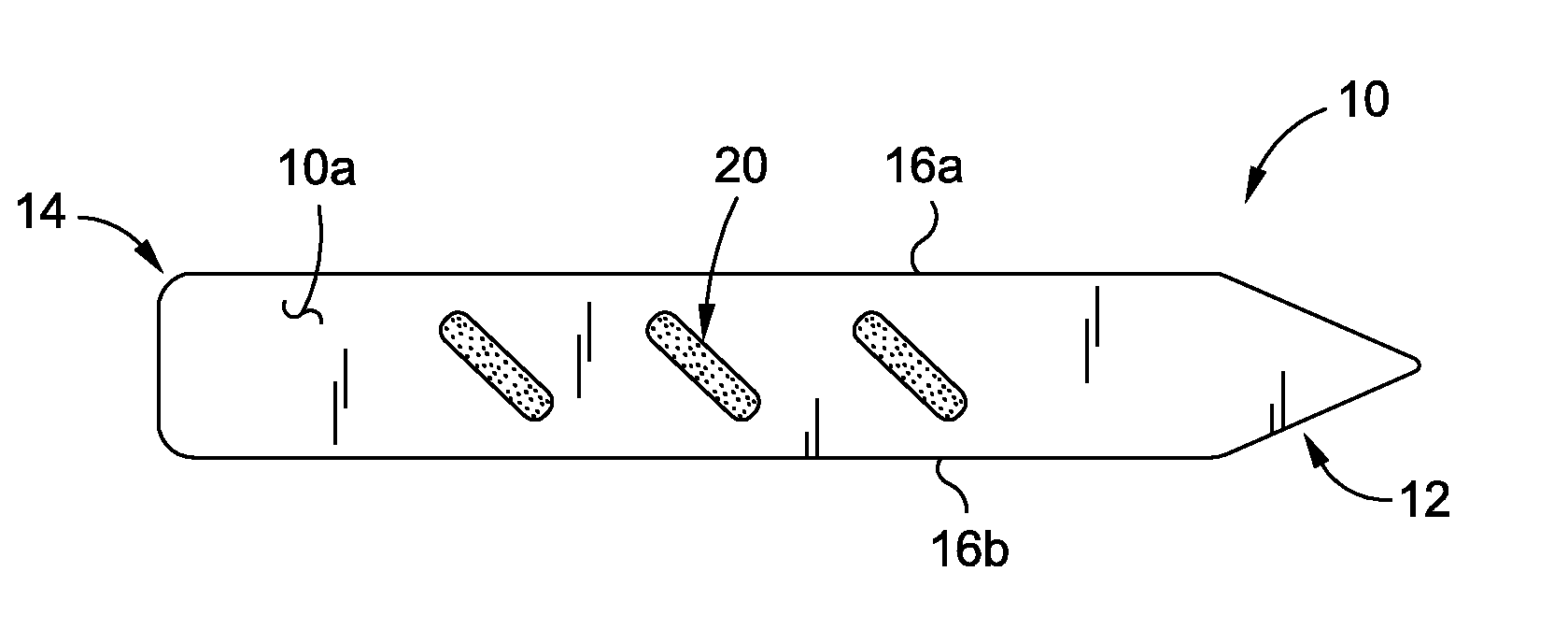

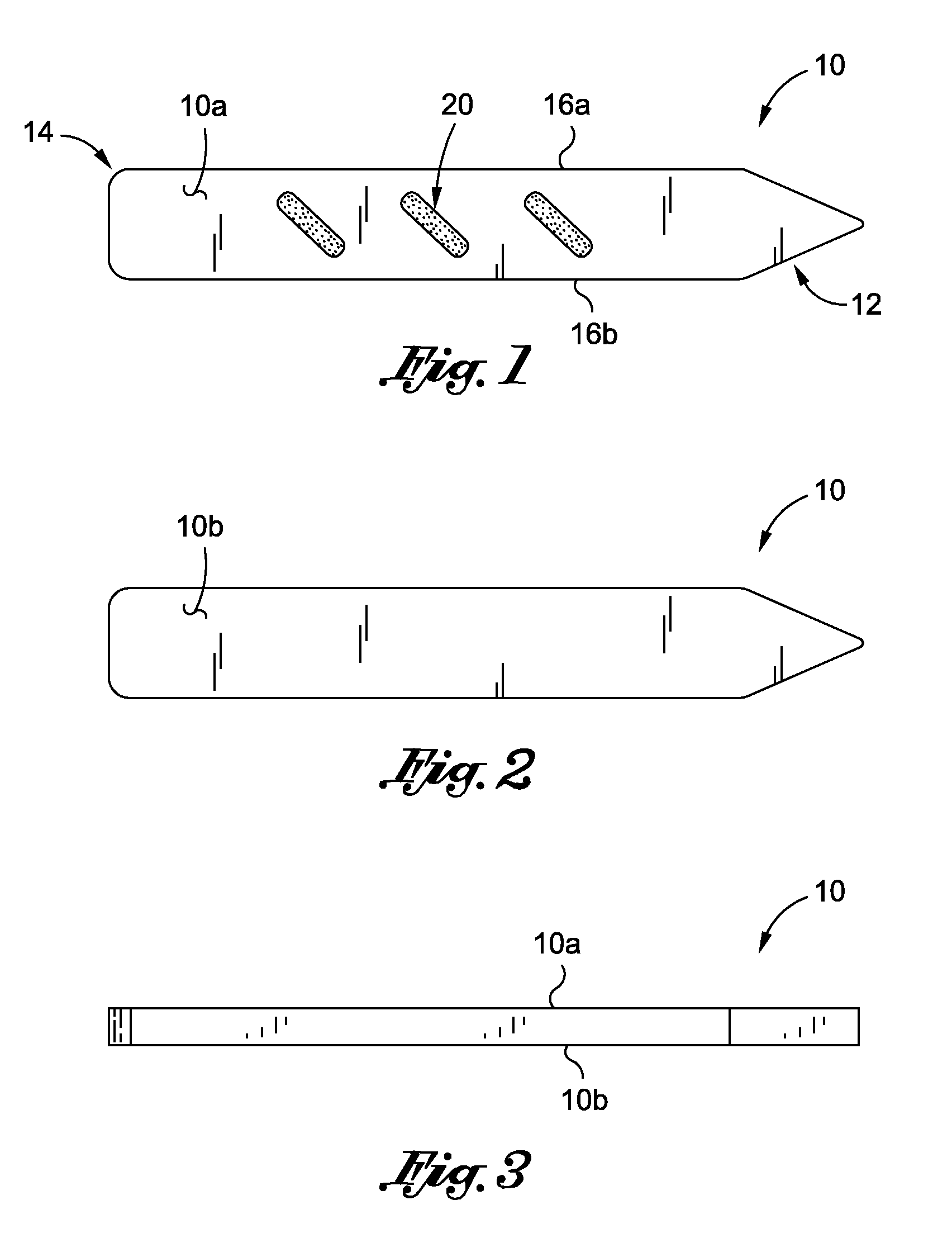

[0016]Referring now to the drawings wherein the showings are for purposes of illustrating a preferred embodiment of the present invention only, and not for purposes of limiting the same, FIGS. 1, 2 and 3 depict a slip resistant collar stay 1 constructed in accordance with the present invention. As shown in FIGS. 1-3, the collar stay 1 comprises an elongate body 10 which defines a generally planar top surface 10a, and an opposed, generally planar bottom surface 10b. The body 10 also defines an opposed pair of longitudinally extending side edges 16a, 16b disposed in spaced, generally parallel relation to each other.

[0017]In the collar stay 1, the side edges 16a, 16b of the body 10 transition to a first end portion 12 of the body 10 which has a generally tapered configuration and terminates at an apex 13. An opposed, second end portion 14 of the body 10 is defined by a laterally extending end surface 15 which extends generally perpendicularly between the side edges 16a, 16b. The transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com