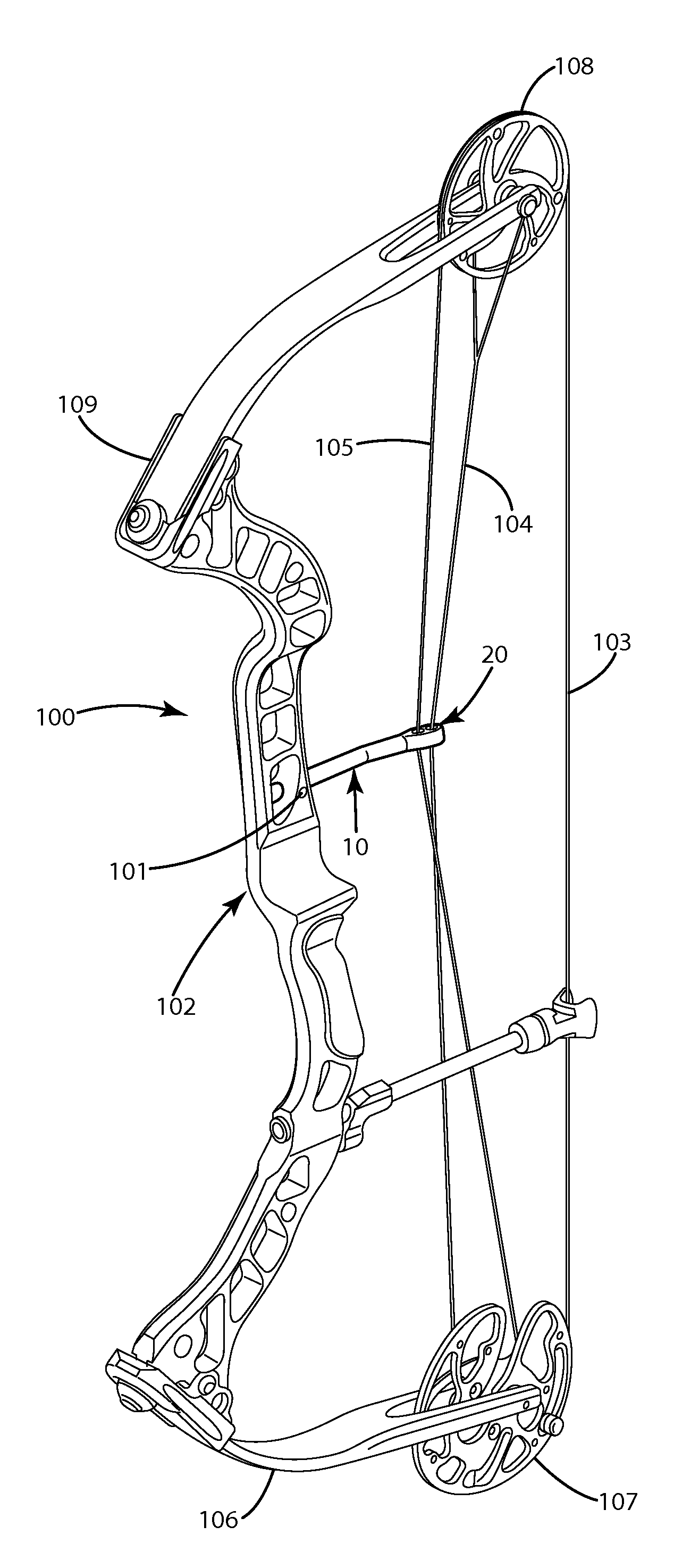

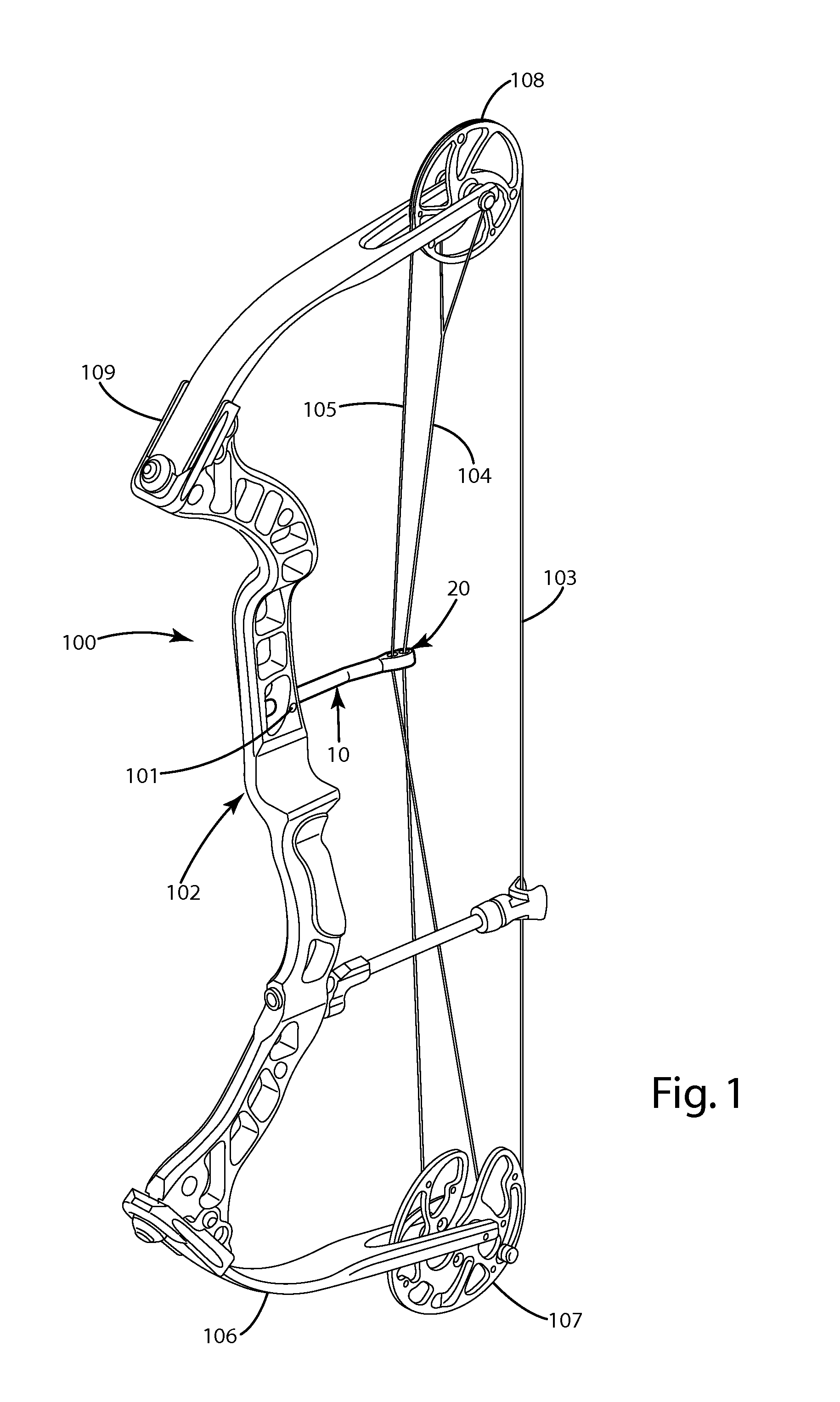

Cable guard and guide for archery bows

a cable guard and archery bow technology, applied in the field of archery bows, can solve the problems of premature wear or abrasion of the cables, affecting the performance of the cable guard, so as to reduce the abrasion of the cable, reduce the friction, and efficiently guide one or more cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first alternative embodiment

III. First Alternative Embodiment

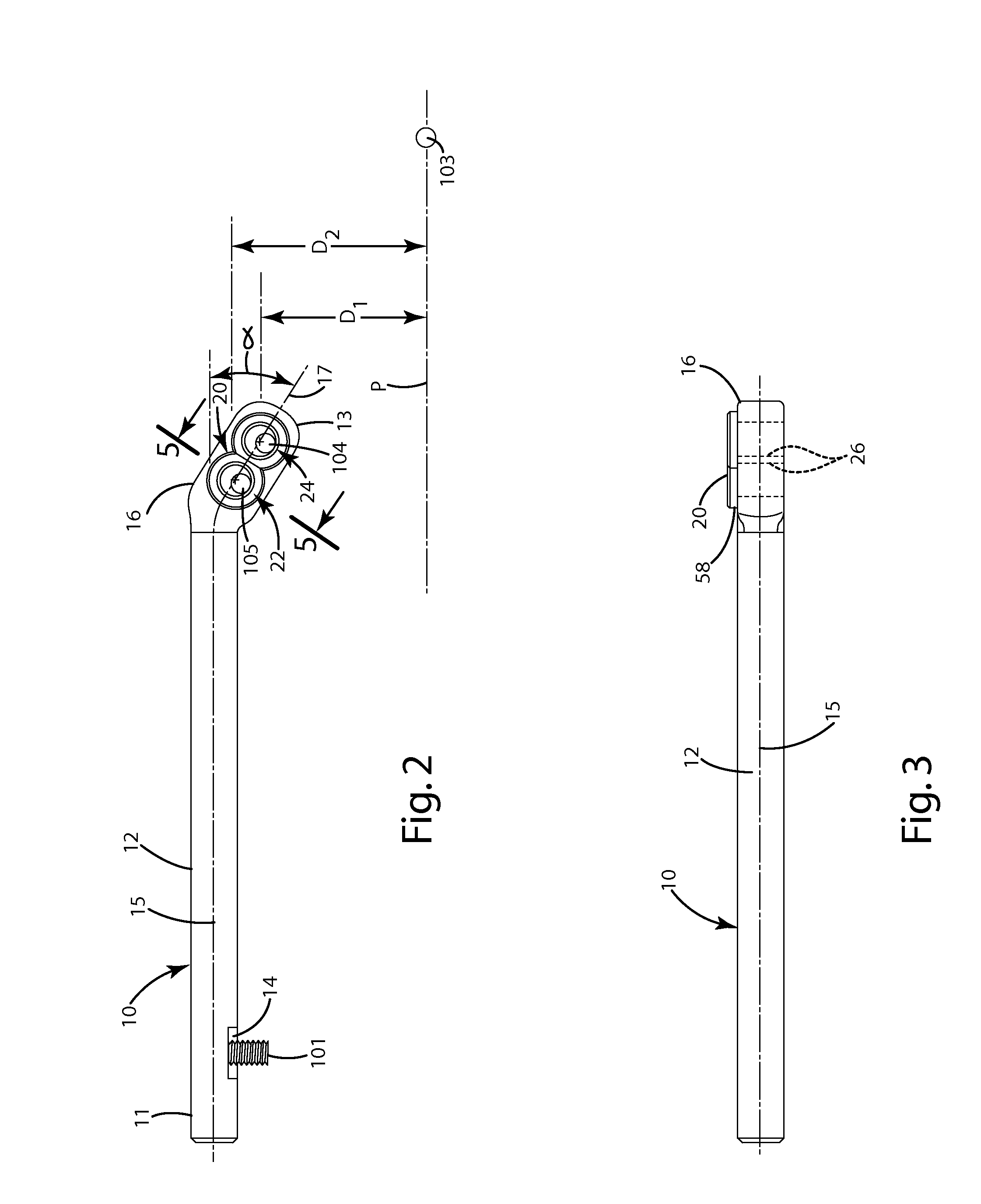

[0052]With reference to FIGS. 6 and 7, a first alternative embodiment of an archery bow including a cable guard and cable guide will now be described. In general, this first alternative embodiment is similar to the embodiment described above with a few exceptions. For example, the cable end 117 of the cable guard 110 is angled at a region 113 closer to the riser end 111 than that of the embodiment described above. The guide portion 116 can be angled relative to the remainder of the bar 112 at an angle α, optionally between about 0 and about 90 degrees, further optionally about 5 and about 35 degrees, and even further optionally about 11 degrees. At these angles, the cable guard 110 can achieve a suitable location of the cables in relation to the bow string 103 and the plane in which the bow string 103 moves. This angle can also provide suitable clearance for the vanes of an arrow shot from the bowstring 103.

[0053]As shown in FIG. 7, this embodiment c...

second alternative embodiment

IV. Second Alternative Embodiment

[0054]Referring to FIGS. 8 and 9, a second alternative embodiment of an archery bow including a cable guard and cable guide will now be described. In general, the second alternative embodiment is similar to the embodiment described above with a few exceptions. For example, instead of defining separate cable guard bores, the cable guard 210 includes a generally oblong or elongated cable guard bore 226 in which a single piece cable guide 220 is inserted. As shown in FIG. 9, that cable guide 220 can be in the form of an oblong cable guide insert 250 which defines cable guide bores 252, which can be configured similar to any of the internal bores of the embodiments described above.

[0055]The cable guide insert 250 can generally be constructed from a single integral piece of low friction material, such as glazed ceramic, or any of the other low friction materials mentioned above. The respective ingresses and egresses of the bores 254, can have radii and / or...

third alternative embodiment

V. Third Alternative Embodiment

[0057]A third alternative embodiment of the archery bow 100 including the cable guard 310 and cable guide 320 is shown in FIGS. 10 and 11. In general, this embodiment is similar to the above embodiments with a few exceptions. For example, this embodiment includes a mounting bracket 60. The mounting bracket 60 includes a boss 62 adapted to be inserted into a bore of the bow riser 302. Optionally, the boss can be held in the bore of the riser 302 by threading or a set screw as described above, or other mechanisms. The mounting bracket also includes an offset portion 65 that extends away from the boss. This offset portion can define a bore 64. The axis of this bore 64 can be offset from the axis of the boss 62. The bore 64 can be sized to provide a sliding fit for the riser end of the cable guard 310.

[0058]The mounting bracket can enable the cable guard 310 to be moved within the bore 64 in the directions shown by the arrow Z, toward and away from the ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com