Knee prostheses

a knee and prosthesis technology, applied in the field of knee prosthesis, can solve the problems of troublesome patellar joint, design that would not allow normal patellar rotation, and patients' discomfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

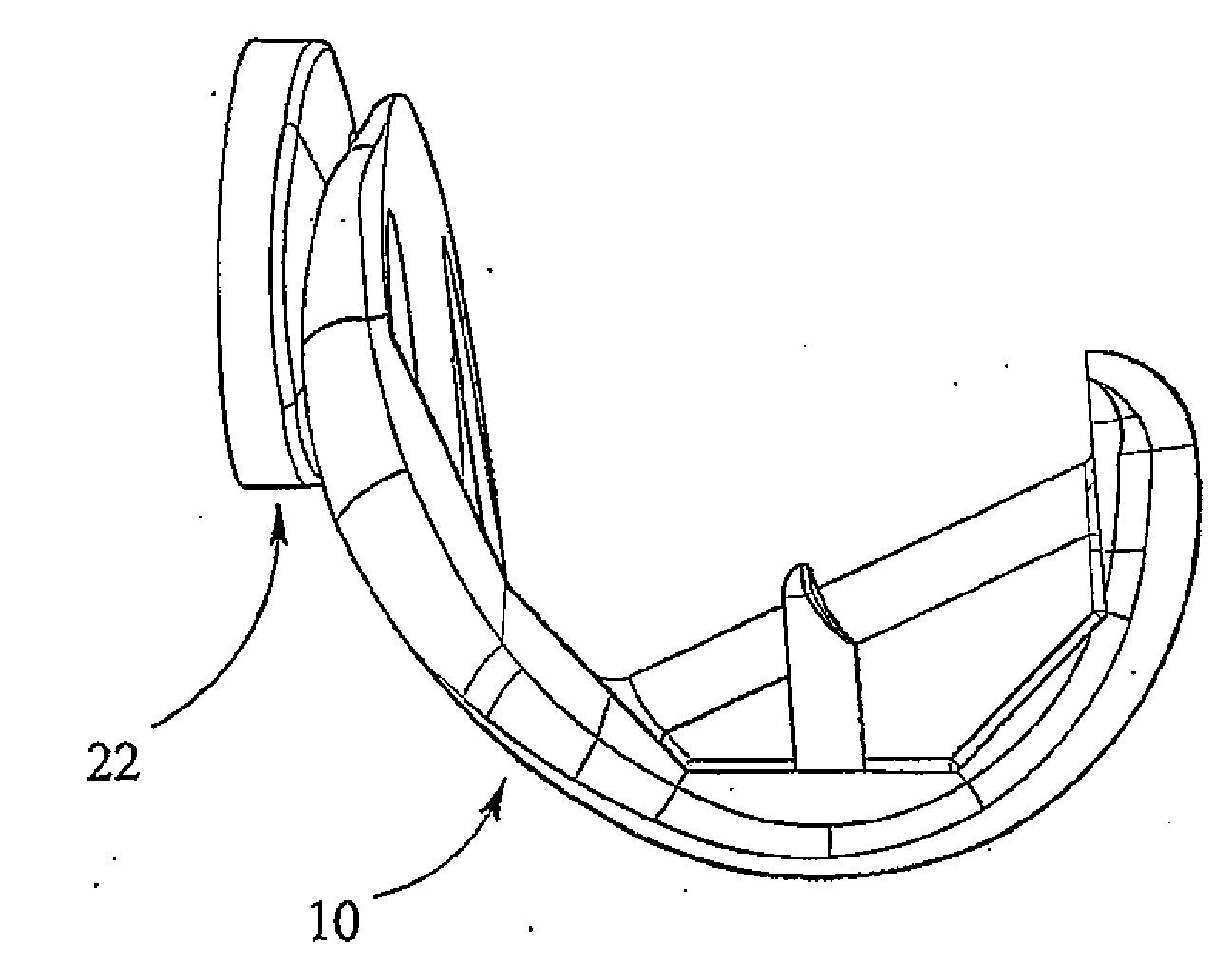

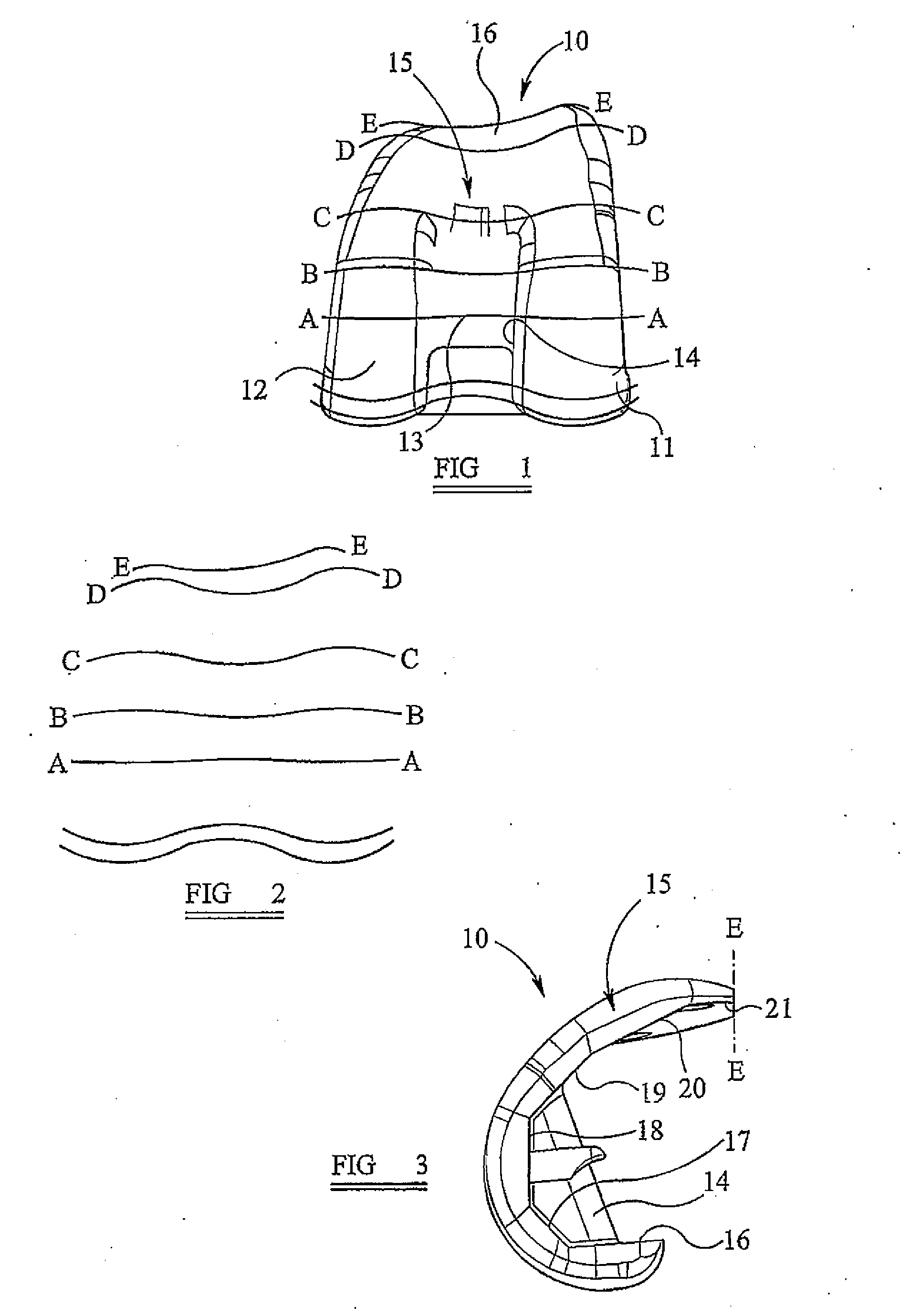

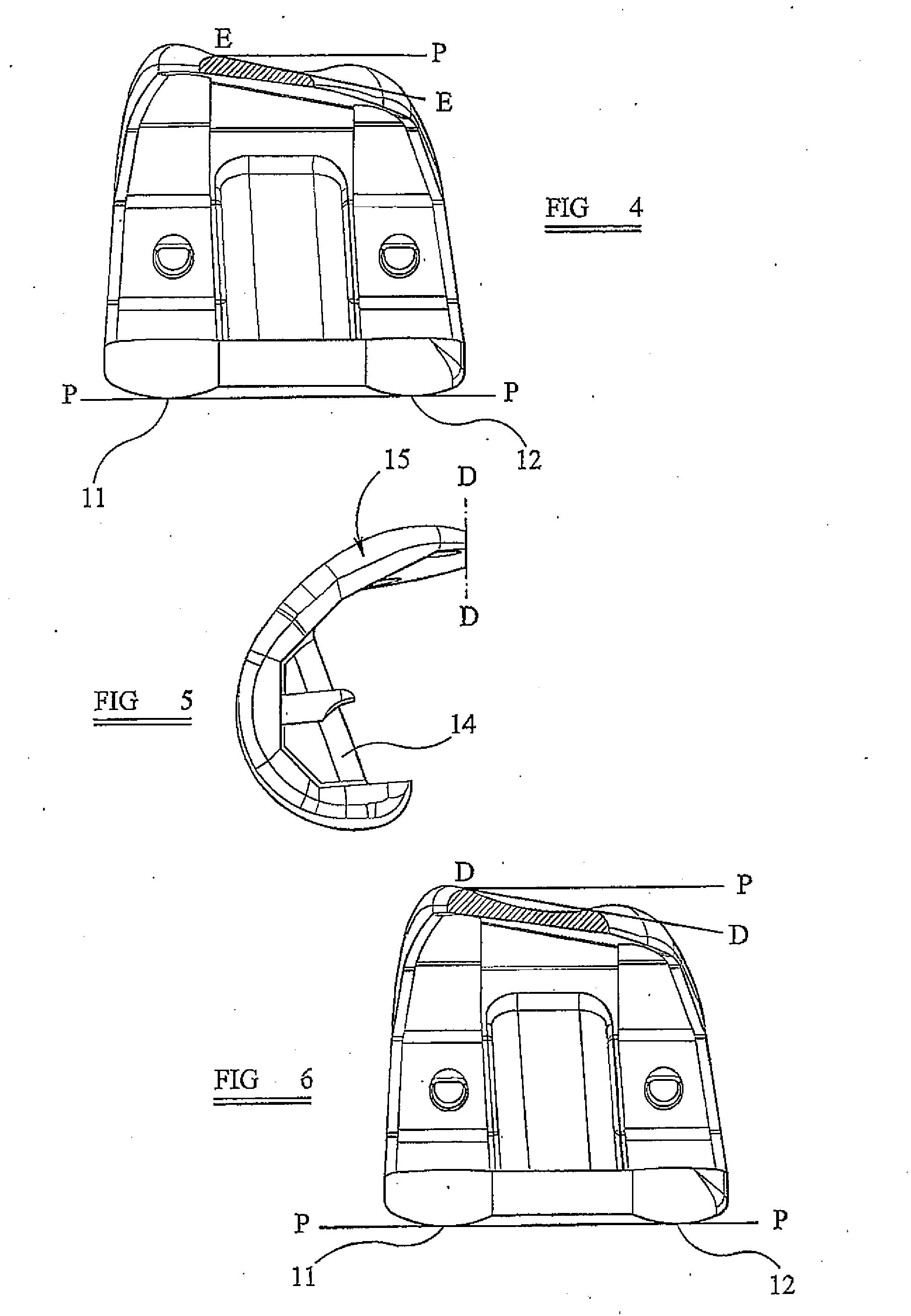

[0064]FIG. 1 shows a femoral component 10 of a knee prosthesis, the femoral component 10 comprising lateral and medial condyles 11, 12 respectively, between which is an open area 13 which, in this embodiment, is enclosed laterally and longitudinally by an intercondylar box 14. However this box could be omitted in an alternative embodiment. Extending away from the condyles 11, 12 and box 14 is a patellar flange 15, having a central patellar groove 16 extending from the box 14 to the free end of the flange 15. As shown, for example, in FIG. 3, the overall internal surface of the femoral component 10 is formed by six discrete flat surfaces 16 to 21 respectively, these, in use, matching six corresponding flat cut surfaces of the patient's femur. This particular arrangement of six flat surfaces may be formed as defined in the Applicant's co-pending UK Published Patent Application No: 2426200.

[0065]According to a first aspect of the invention, as shown best in FIGS. 1 and 2, a twist is bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com