Cooling fin pipe smoker

a technology for smoking fin pipes and tobacco pipes, applied in tobacco pipes, applications, tobacco, etc., can solve the problems of unburned tobacco, unburned tobacco, and unburned tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009]While the invention is described herein with the reference to a number of embodiments and methods of use, it should be understood that the invention should not be limited to such embodiments or uses. The description of the embodiments and uses herein are illustrative only and should not limit the scope of the invention as claimed. Embodiments are presented in the figures, which are not drawn to scale and in which like components are numbered alike.

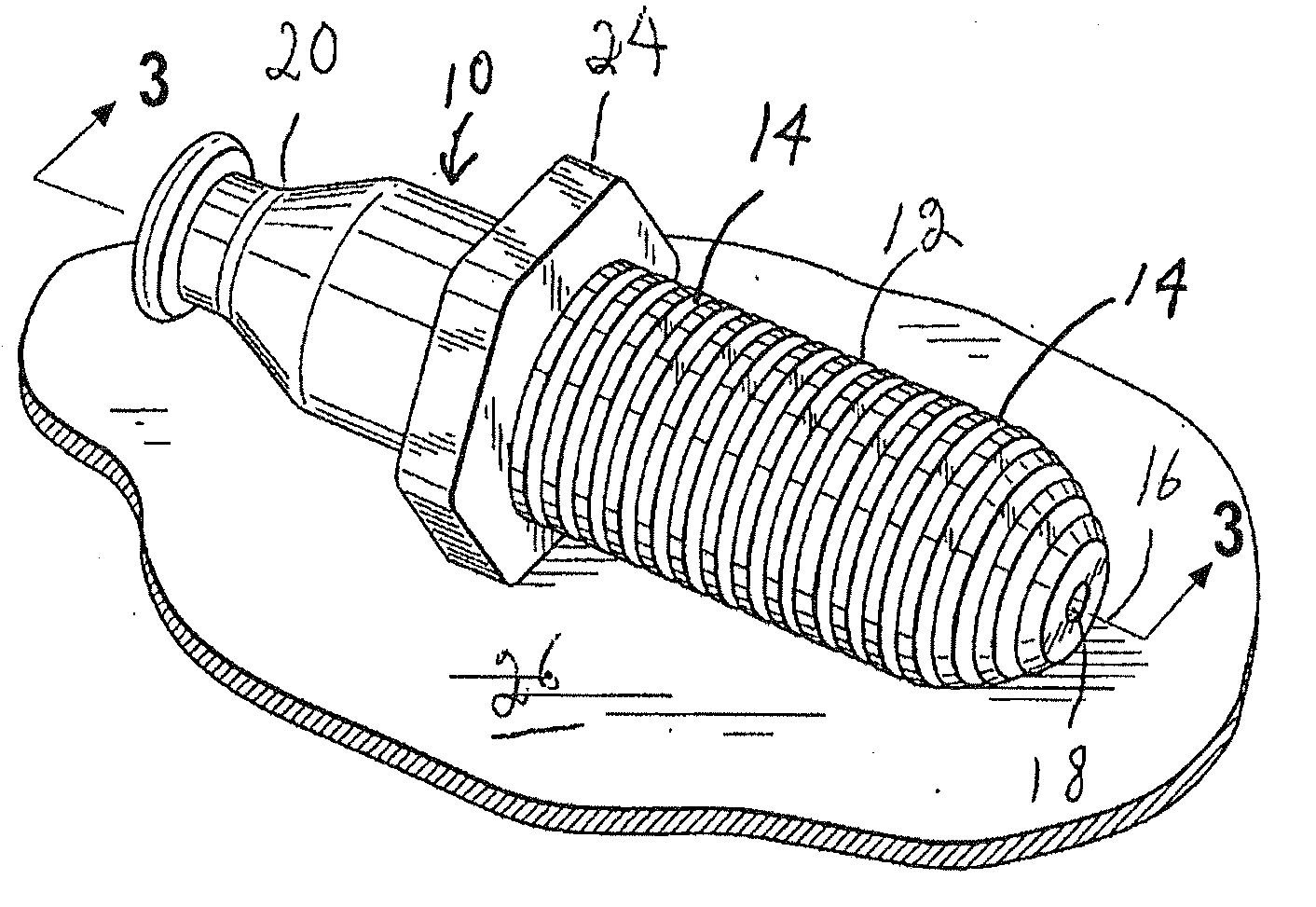

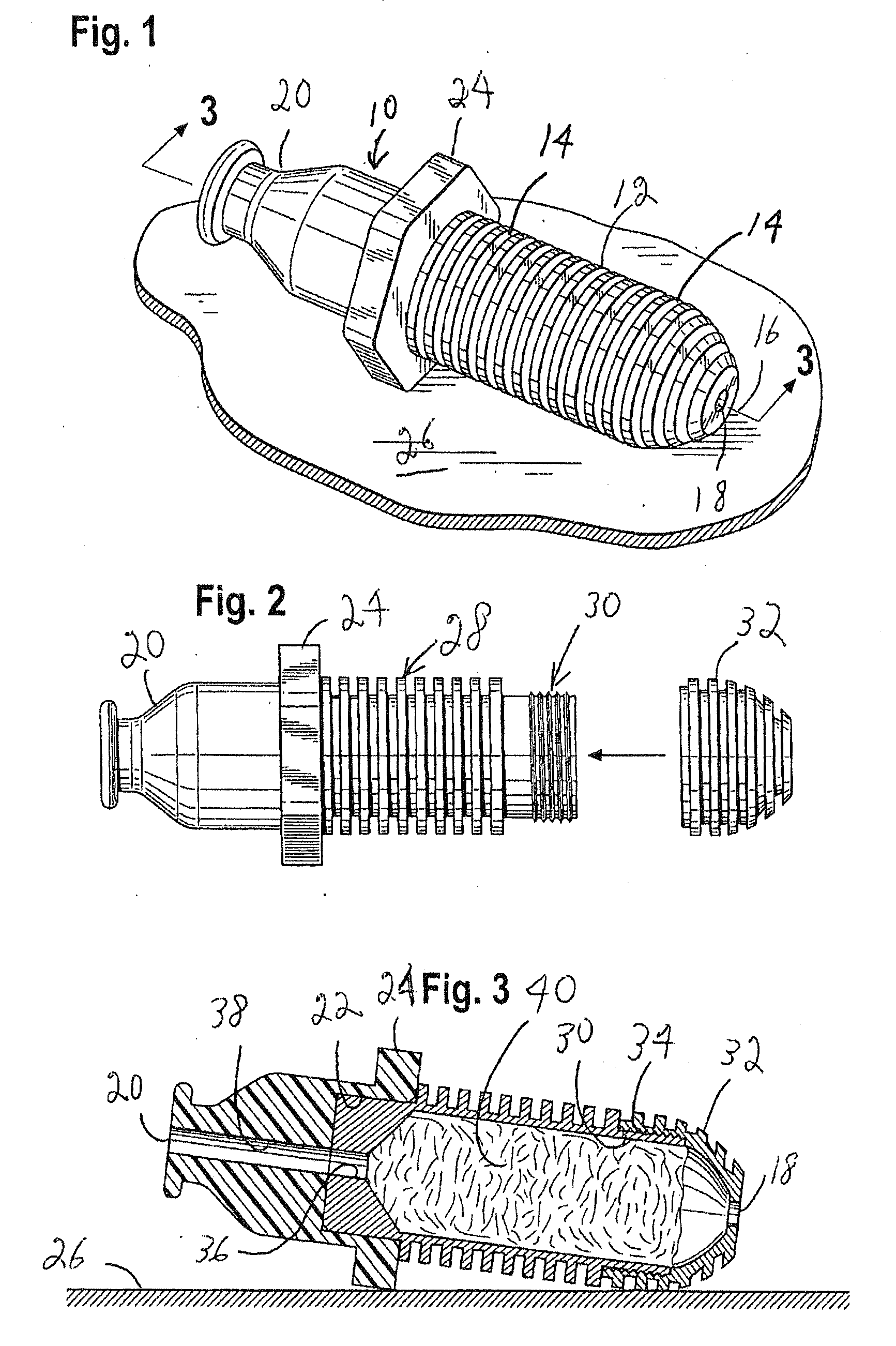

[0010]Apparatus for tobacco smoking within a pipe includes exterior males threads on the outer surface of the bowl end joining the cap and corresponding matching female threads on the interior of the cap providing a mechanical locking of the cap to the bowl once tobacco is inserted within the bowl to fixedly join the bowl and cap together for use. The cooling fins are spaced apart in a parallel relationship with respect to each other and extend outwardly from the outer surface of the bowl and cap a predetermined distance that is perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com