Tilt-up wall brace dolly and method of use

a wall brace and dolly technology, applied in the direction of walls, building scaffolds, building repairs, etc., can solve the problems of generating labor costs and adding construction costs to the construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

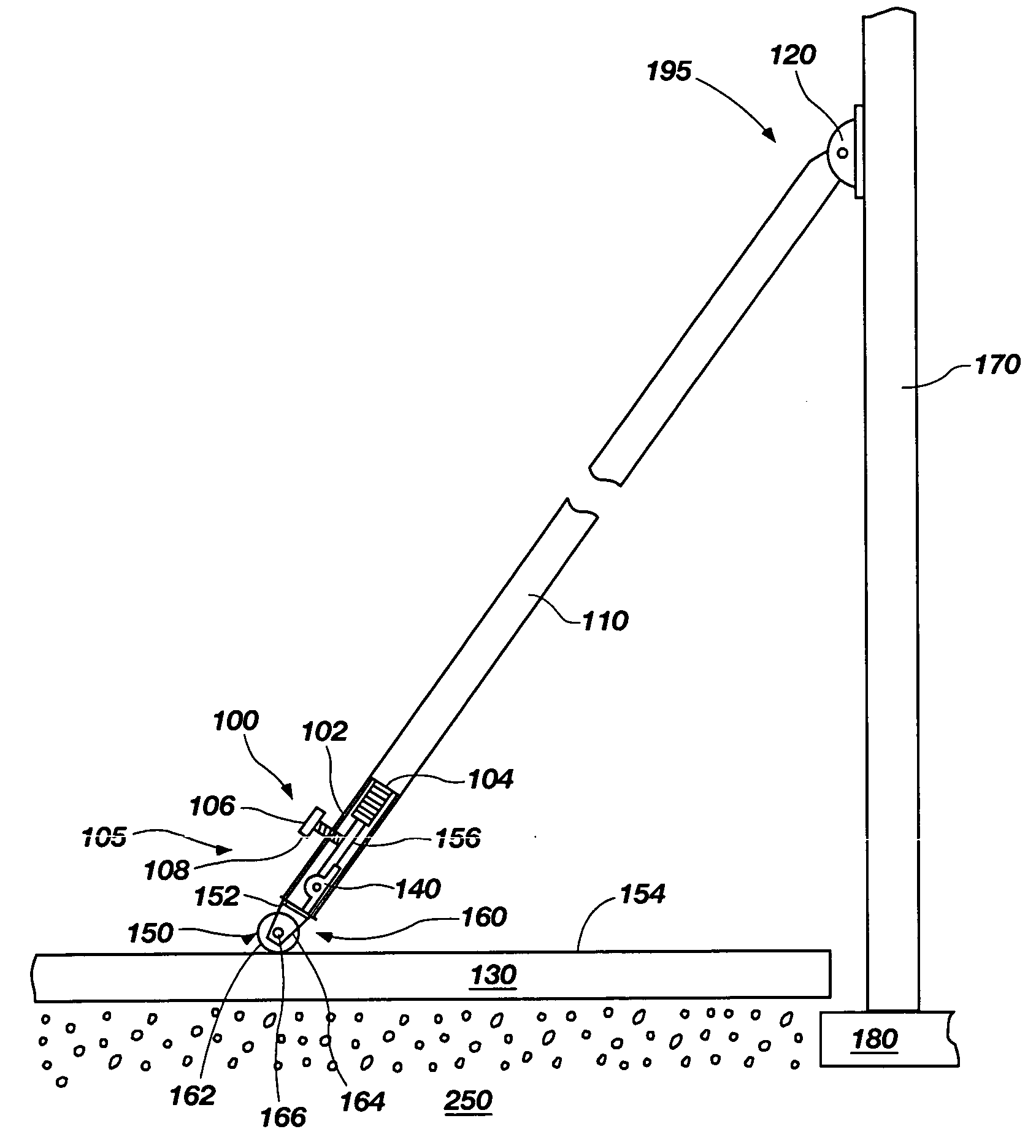

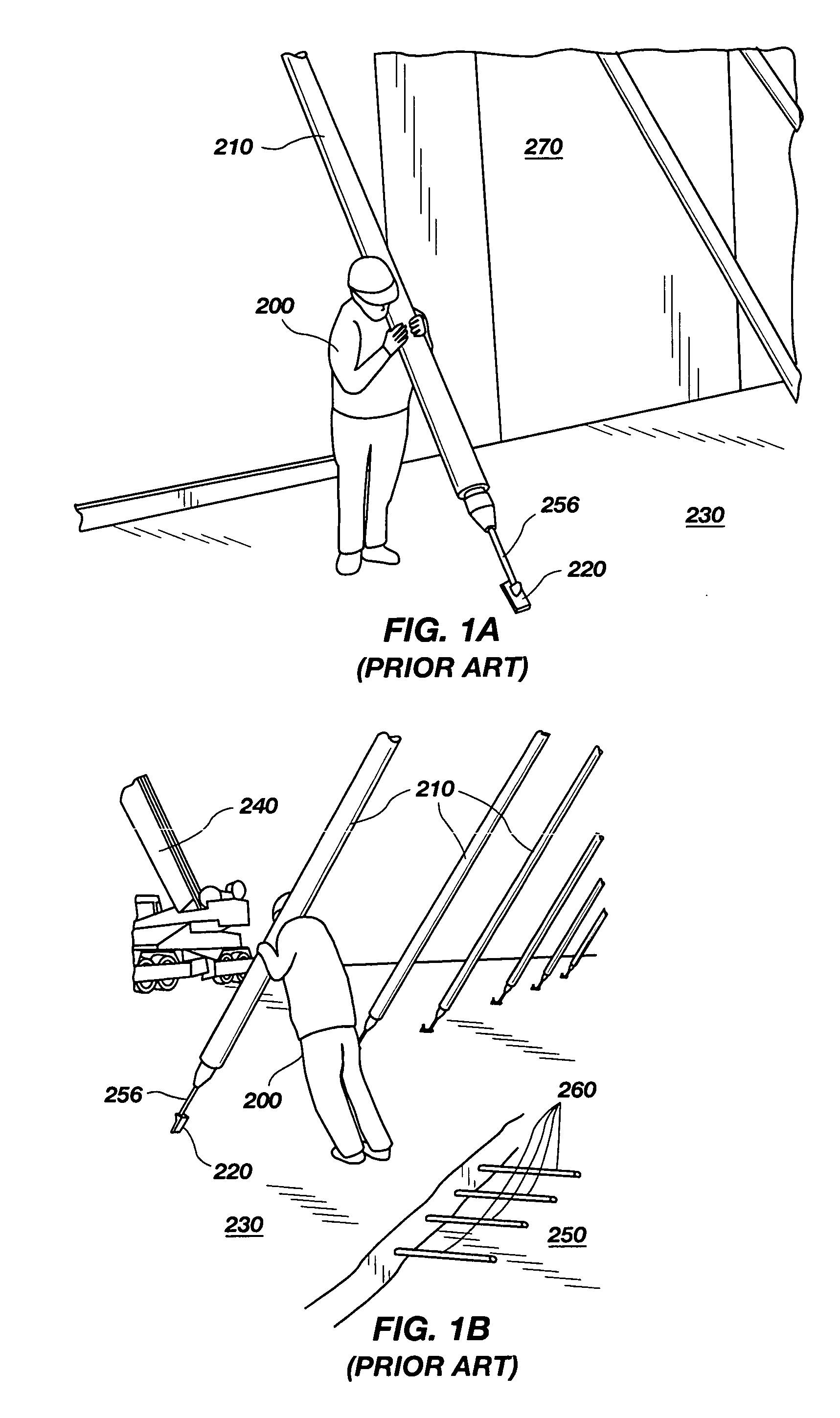

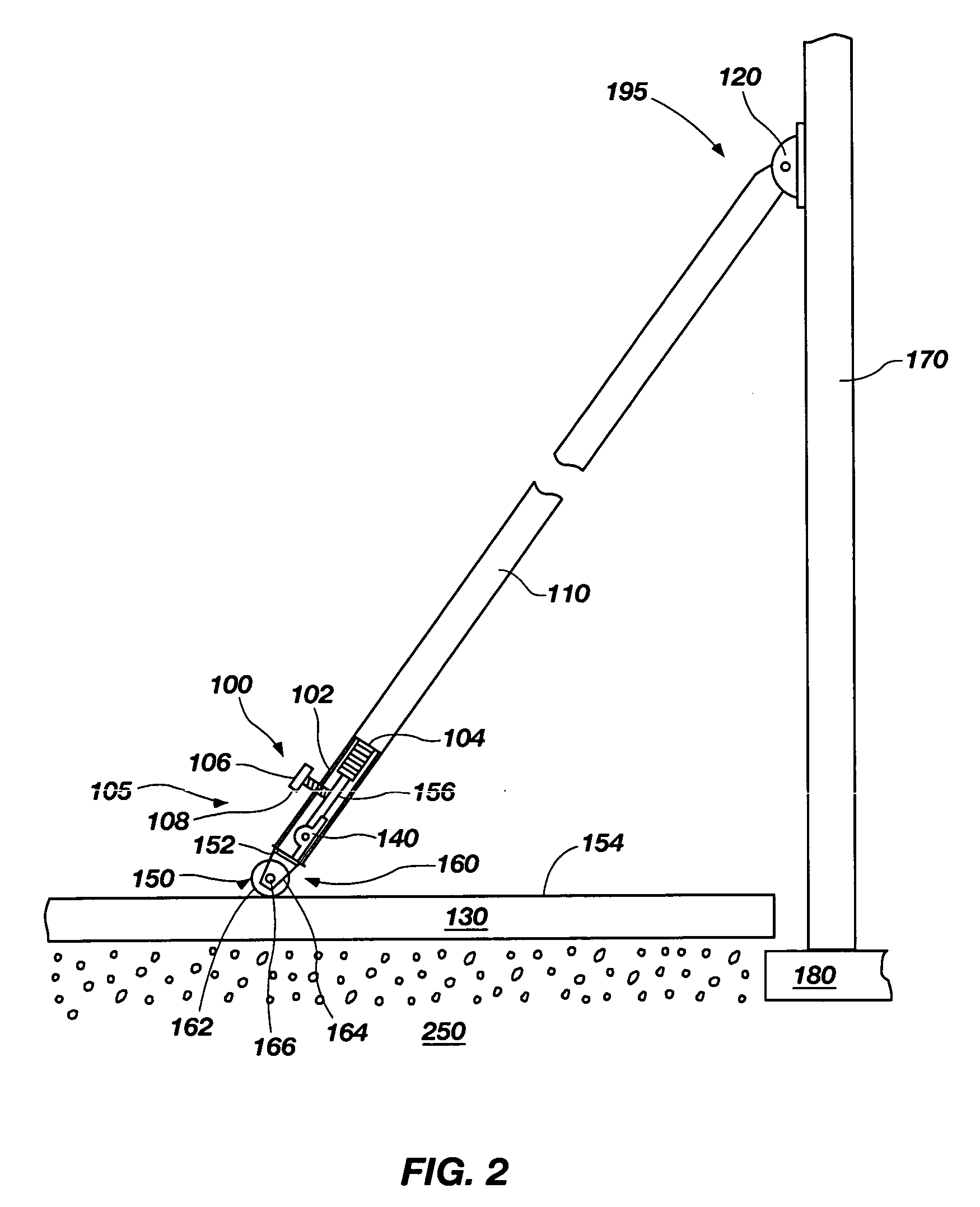

[0022]The invention is a tilt-up wall brace dolly and method of use. The embodiments of the invention are useful in the construction industry, particularly the erection and temporary bracing of tilt-up walls. Embodiments of a tilt-up wall brace dolly according to the present invention may be configured for use, or attached to, conventional tilt-up wall braces, or may be integrated into novel tilt-up wall braces. The embodiments of a tilt-up wall brace dolly illustrated and described herein are particularly useful for positioning the lower end of a tilt-up wall brace along a floor slab surface (inside of a building) or along a flat surface outside of a building during erection of a tilt-up wall. The embodiments of the invention disclosed herein may reduce construction worker fatigue. The embodiments of the invention may also reduce possible injury to construction workers during positioning of tilt-up wall braces.

[0023]FIG. 2 is a side-view of an embodiment of a tilt-up wall brace dol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com