Hand puller with a structure of double stopping plates

a technology of stopping plate and hand puller, which is applied in the direction of fastenings, press-button fasteners, transportation items, etc., can solve the problems of increasing the cost of hand pullers and releasing straps too much

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The present invention will be apparent from the following detailed description, which proceeds with reference to the accompanying drawings, wherein the same references relate to the same elements.

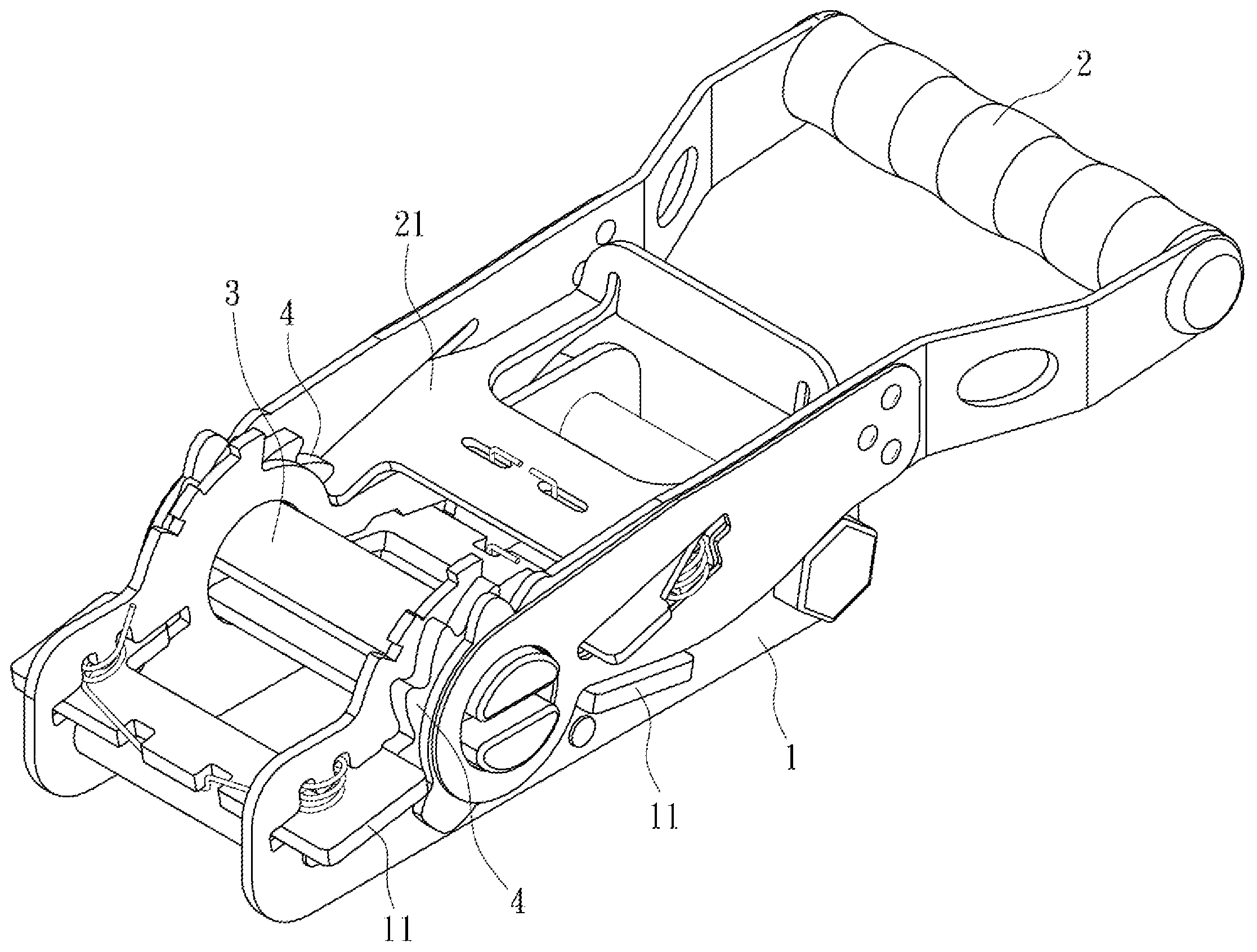

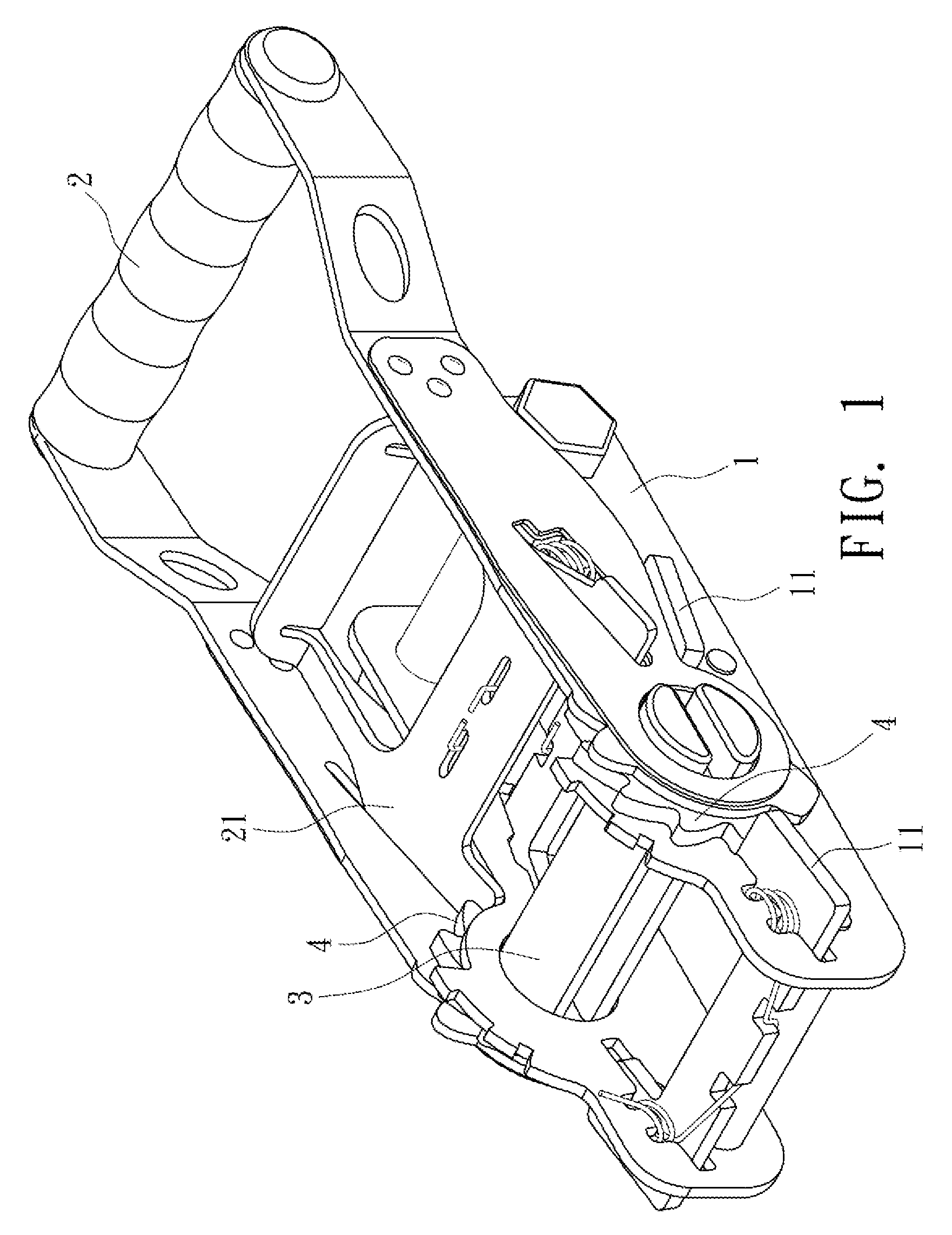

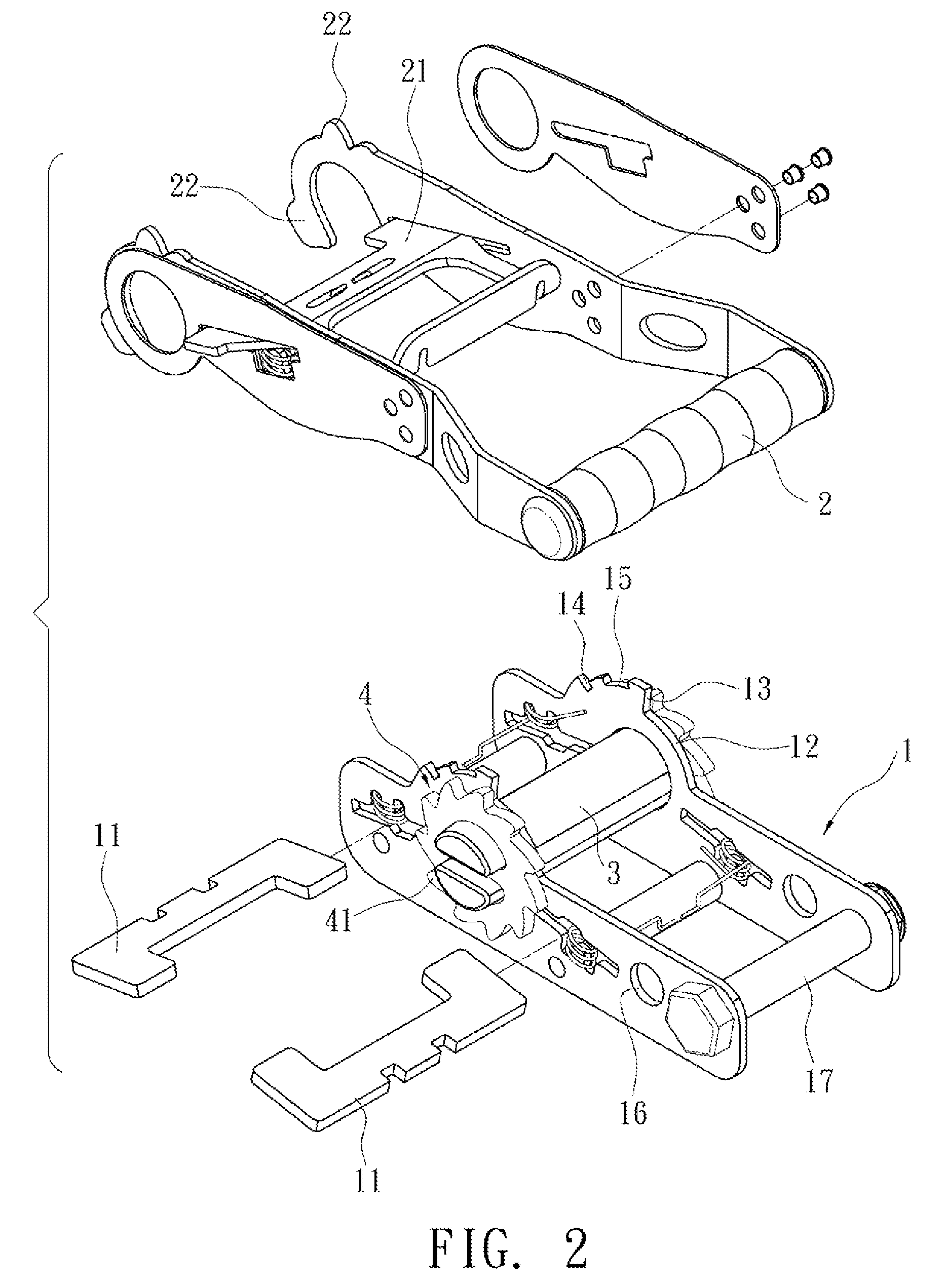

Please refer to FIGS. 1 to 7 for an embodiment of the invention. It is used only for the illustration purpose. The invention is not restricted to such a structure.

This embodiment provides an improved hand puller. An axle part 3 goes through a fixing part I and a pulling part 2. Both ends of the axle part 3 are provided with a ratchet 4, respectively. The fixing part 1 has stopping plates I1. The pulling part 2 has a driving claw 21. The stopping plate 11 and the driving claw 21 engage with the teeth 41 of the ratchet 4. As shown in FIG. 2, the pulling part 2 can depart from the fixing part 1.

The fixing part 1 has a stopping plate 11 ob opposite ends of the axle 3, respectively. When the driving claw 21 drives the ratchet 4, the stopping plate 11 on one side of the ratchet 4 engages with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com