double check seat

A valve seat and air chamber technology, applied in the field of double-blocking actuators, can solve problems such as mechanical noise, affecting service life, environmental noise pollution, etc., and achieve the effects of reducing impact force, prolonging service life, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

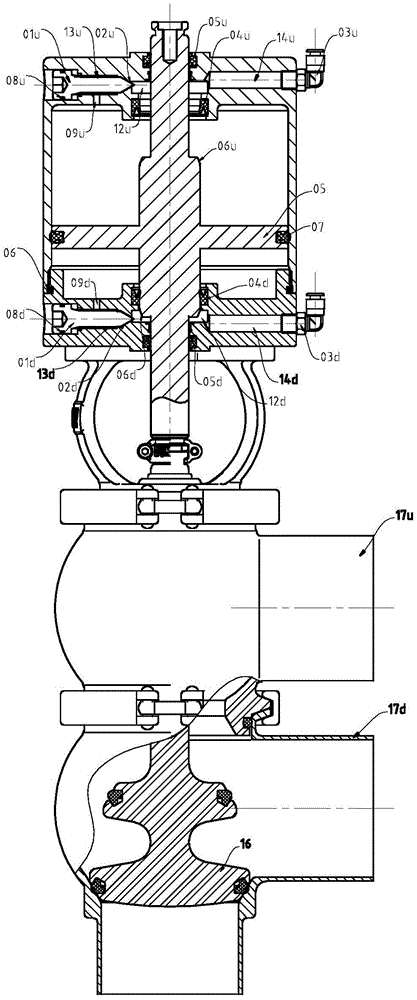

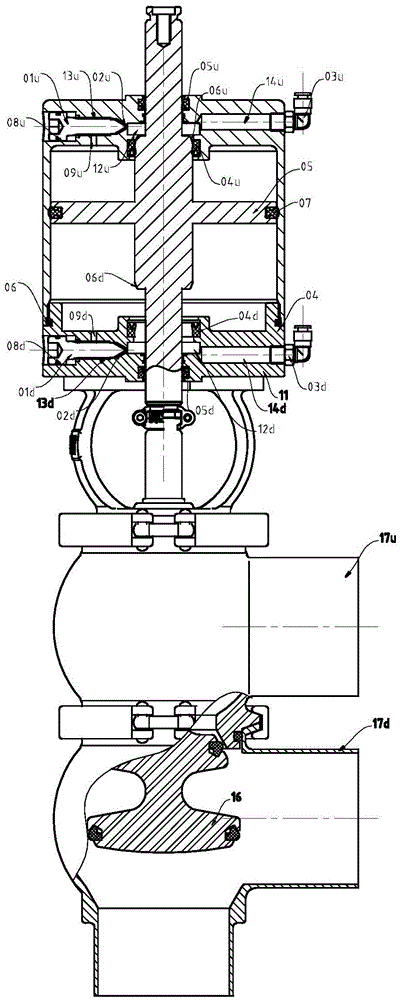

[0010] Such as figure 1 The actuator part of the middle double block valve seat, the pneumatic actuator of the double block valve seat is composed of a closed upper and lower cover. Yes, the upper and lower covers of the cylinder each have an air nozzle 03u, 03d, the function is to inflate and exhaust the two air chambers of the cylinder, and the piston 05 reciprocates up and down under the alternate inflation and exhaust pressure of the air nozzles 03u and 03d , the valve seat spool 16 connected with the piston 05 moves back and forth synchronously, so as to realize the switch function between the valve core 16 and the valve seats 17u, 17d, and realize the control of the valve.

[0011] The actuator of the seat valve is a closed body composed of upper and lower covers. The piston separates the body into upper and lower air chambers. The function of the two piston sealing rings 06 and 07 is sealing.

[0012] When the piston moves, there are two paths for exhaust gas, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com