Liquid crystal display using polymer stability alignment process with sealant pre-curing process

a liquid crystal display and polymer stability technology, applied in non-linear optics, instruments, optics, etc., can solve the problems of reducing the brightness of the lcd, increasing the complexity and cost of fabrication, and reducing the aperture ratio of the pixel, so as to prevent the possibility of inferior thermal stability during the curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

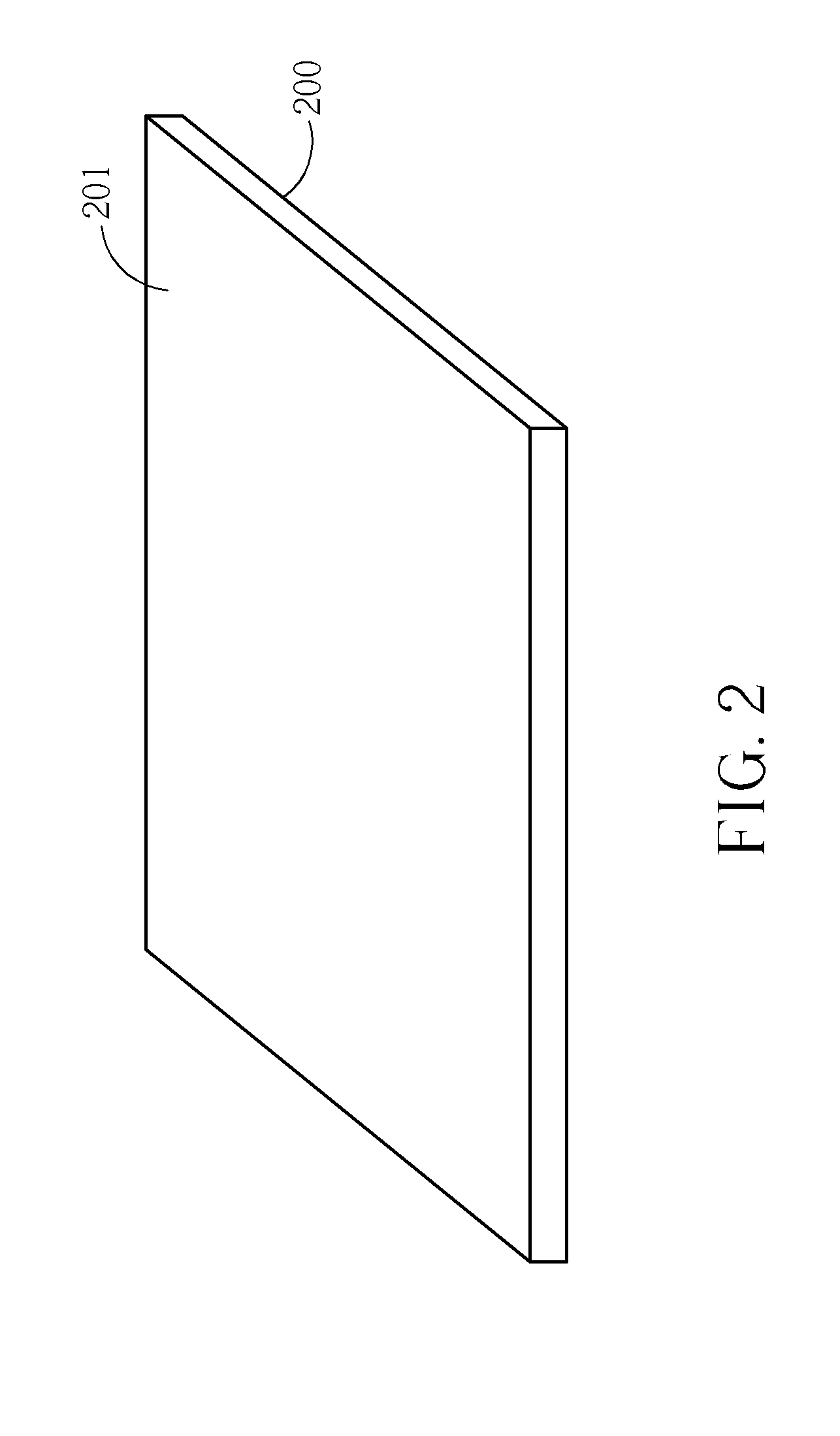

[0016]According to the present invention, the presently used reactive monomer is easy to be deteriorated or have other chemical reaction when the presently used reactive monomer is heated to a thermal-curing temperature of aforementioned sealant. Therefore, the presently used reactive monomer has a problem of inferior thermal stability, so that the reactive monomer has no function during the polymer stability alignment process so as to cause mura of a liquid crystal display (LCD). The present invention provides choices for the materials of the reactive monomer and a method for manufacturing the LCD as a whole to improve the problem in the art.

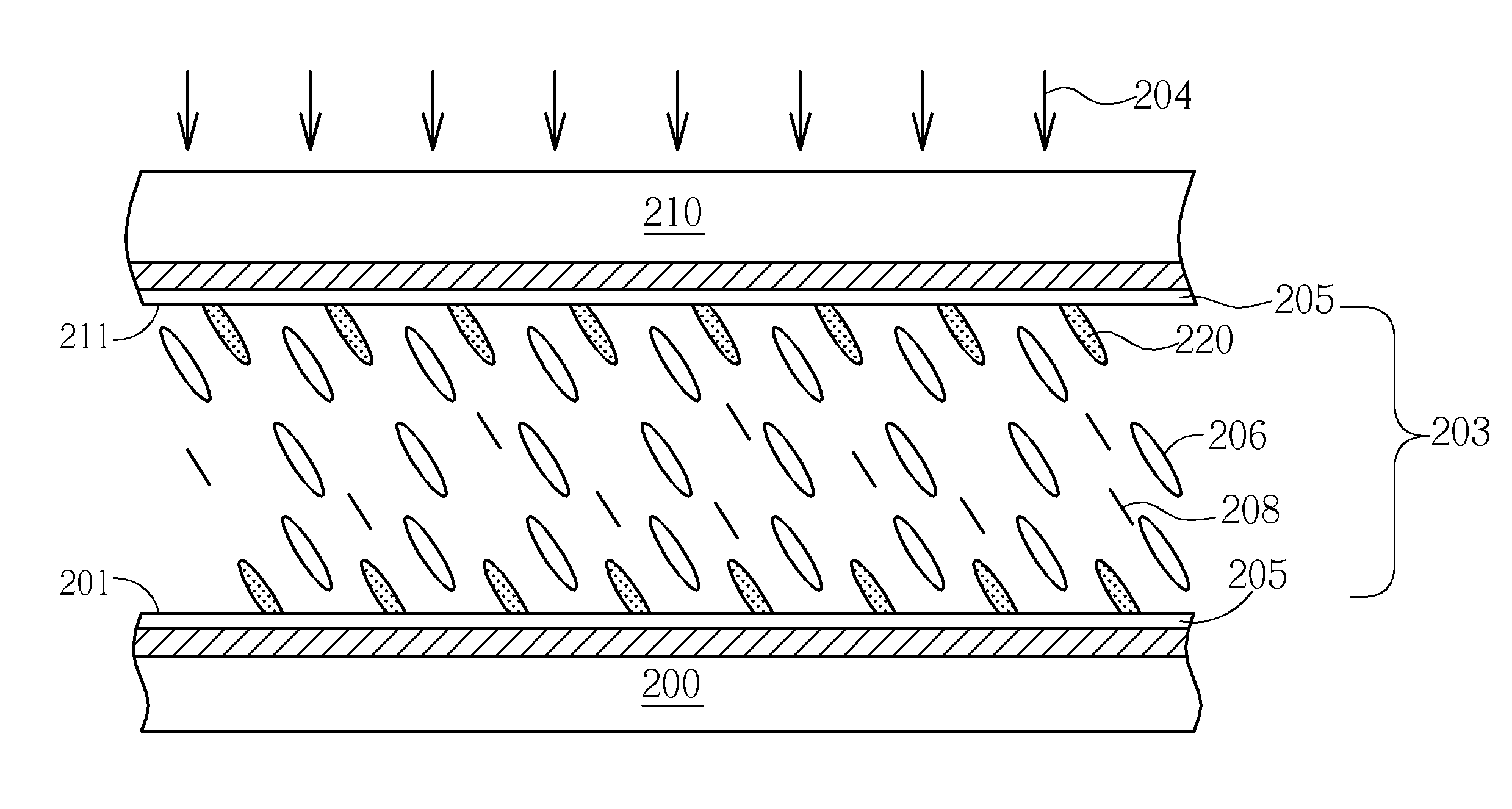

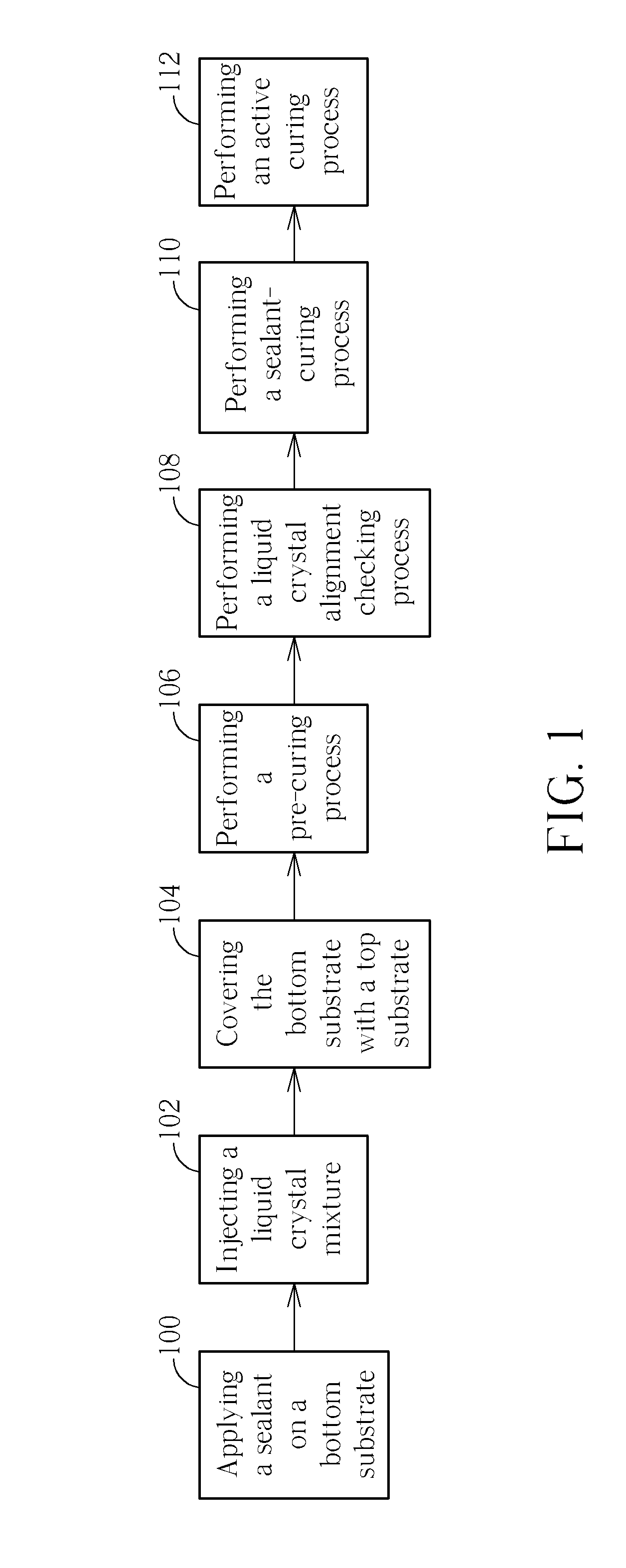

[0017]Please refer to FIG. 1 through FIG. 7. FIG. 1 is a flowchart of a method for manufacturing the LCD according to the present invention. FIG. 2 through FIG. 7 are schematic diagrams of a process for manufacturing the LCD according to the present invention. The LCD is manufactured mainly by a one drop fill process and a polymer stability ali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| curing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com