LED drive circuit, phase control dimmer, LED illumination fixture, LED illumination device, and LED illumination system

a technology of led drive circuit and phase control dimmer, which is applied in the direction of electric variable regulation, process and machine control, instruments, etc., can solve the problem of not being able to achieve normal dimming, and achieve the effect of reducing led flicker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

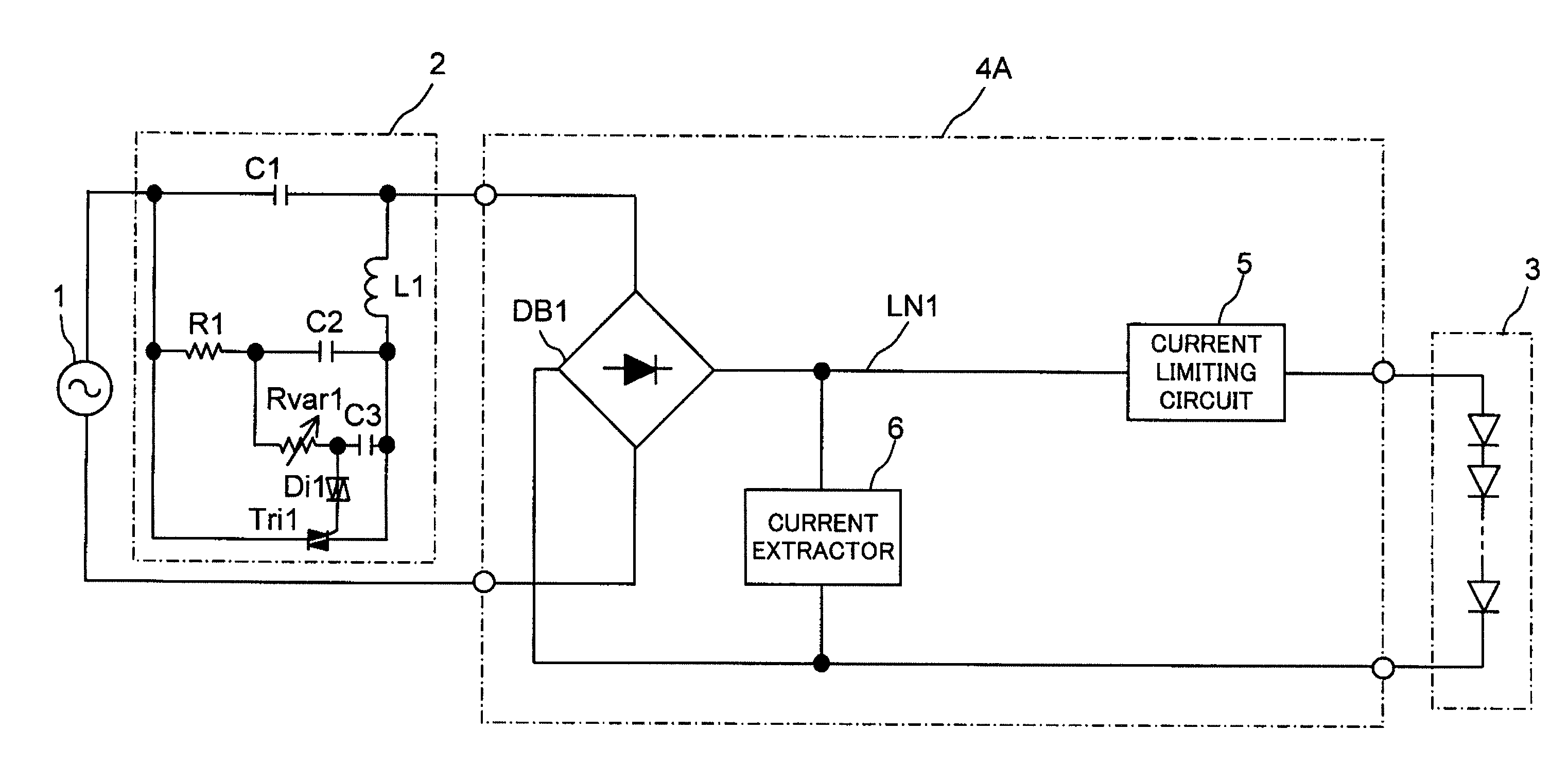

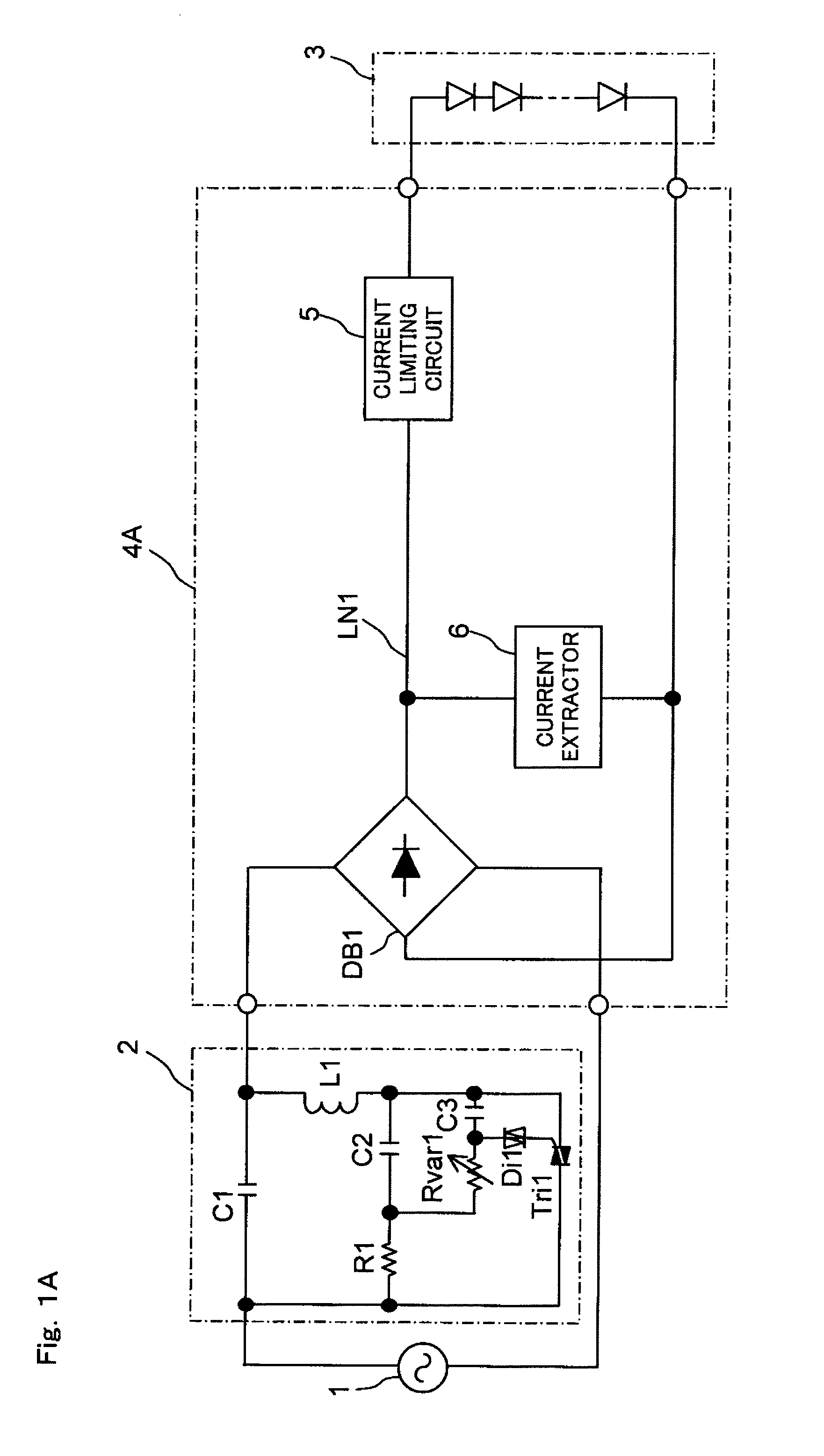

[0068]FIG. 1A shows the configuration of the LED illumination system according to a first embodiment of the present invention. The same reference symbols are used in FIG. 1A to refer to components that are the same as those in FIG. 17, and no detailed description thereof will be given. The LED illumination system according to the first embodiment of the present invention shown in FIG. 1A is provided with a phase control dimmer 2, an LED module 3, and an LED drive circuit 4A. The LED drive circuit 4A is an example of the LED drive circuit according to the present invention and is a direct-type (non-switching type) LED drive circuit, and has a diode bridge DB1, a current limiting circuit 5, and a current extractor 6. The current extractor 6 is provided between the output terminals of the diode bridge DB1, and extracts a current from a power supply feed line LN1 for feeding an LED drive current to the LED module 3 during operation. In the LED illumination system according to the first ...

second embodiment

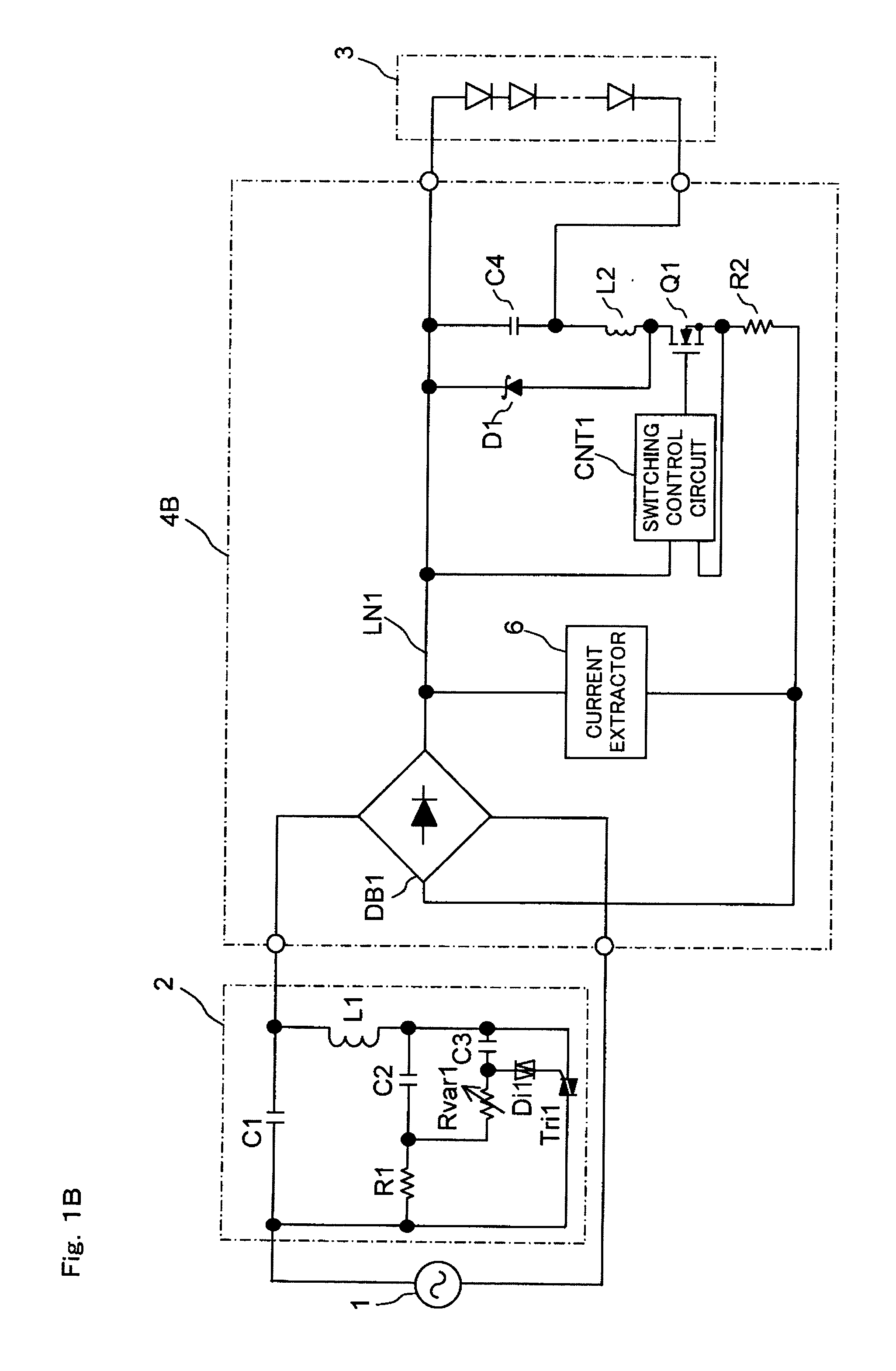

[0070]FIG. 1B shows the configuration of the LED illumination system according to a second embodiment of the present invention. The same reference symbols are used in FIG. 1B to refer to components that are the same as those in FIG. 18, and no detailed description thereof will be given. The LED illumination system according to the present invention shown in FIG. 1B is provided with a phase control dimmer 2, an LED module 3, and an LED drive circuit 4B. The LED drive circuit 4B is another example of the LED drive circuit according to the present invention, and is a switching-type LED drive circuit having a diode bridge DB1, a switching control circuit CNT1, a switching element Q1, a coil L2, a diode D1, a capacitor C4, a resistor R2, and a current extractor 6. The current extractor 6 is provided between the output terminals of the diode bridge DB1, and extracts a current from a power supply feed line LN1 for feeding an LED drive current to the LED module 3 during operation. In the LE...

third embodiment

[0072]FIG. 2 shows the configuration of the LED illumination system according to a third embodiment of the present invention. The same reference symbols are used in FIG. 2 to refer to components that are the same as those in FIG. 17, and no detailed description thereof will be given. The LED illumination system according to the third embodiment of the present invention shown in FIG. 2 is provided with a phase control dimmer 2′, an LED module 3, and an LED drive circuit 4. The LED drive circuit 4 is a direct-type (non-switching type) LED drive circuit, and has a diode bridge DB1 and a current limiting circuit 5. In the LED illumination system according to the third embodiment of the present invention shown in FIG. 2, the phase control dimmer 2′ is provided between an alternating-current power supply 1 and the input terminal of the LED drive circuit 4, and the LED module 3 composed of one or more LED elements is provided between the output terminals of the LED drive circuit 4.

[0073]Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com