Collapsible crate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

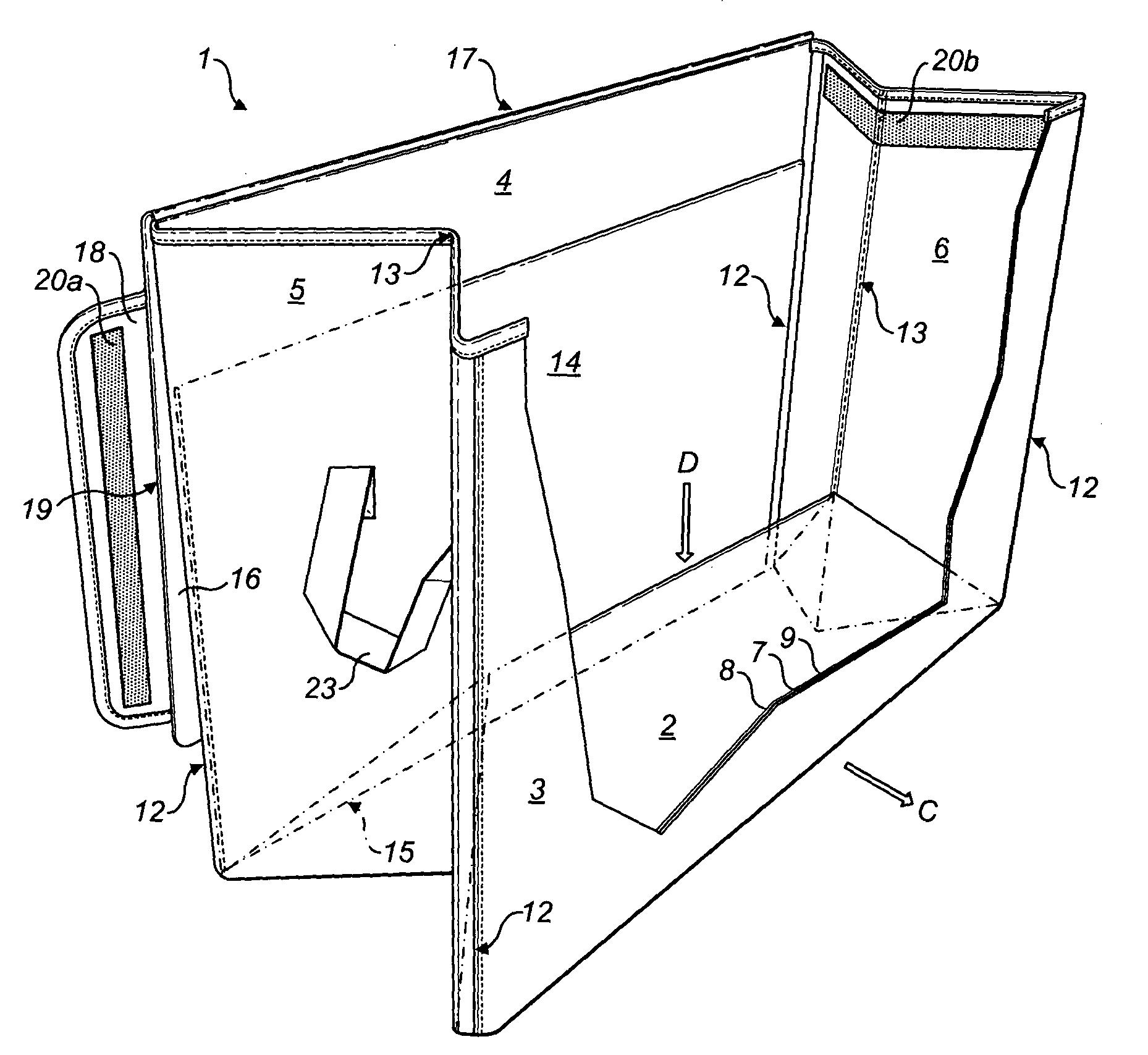

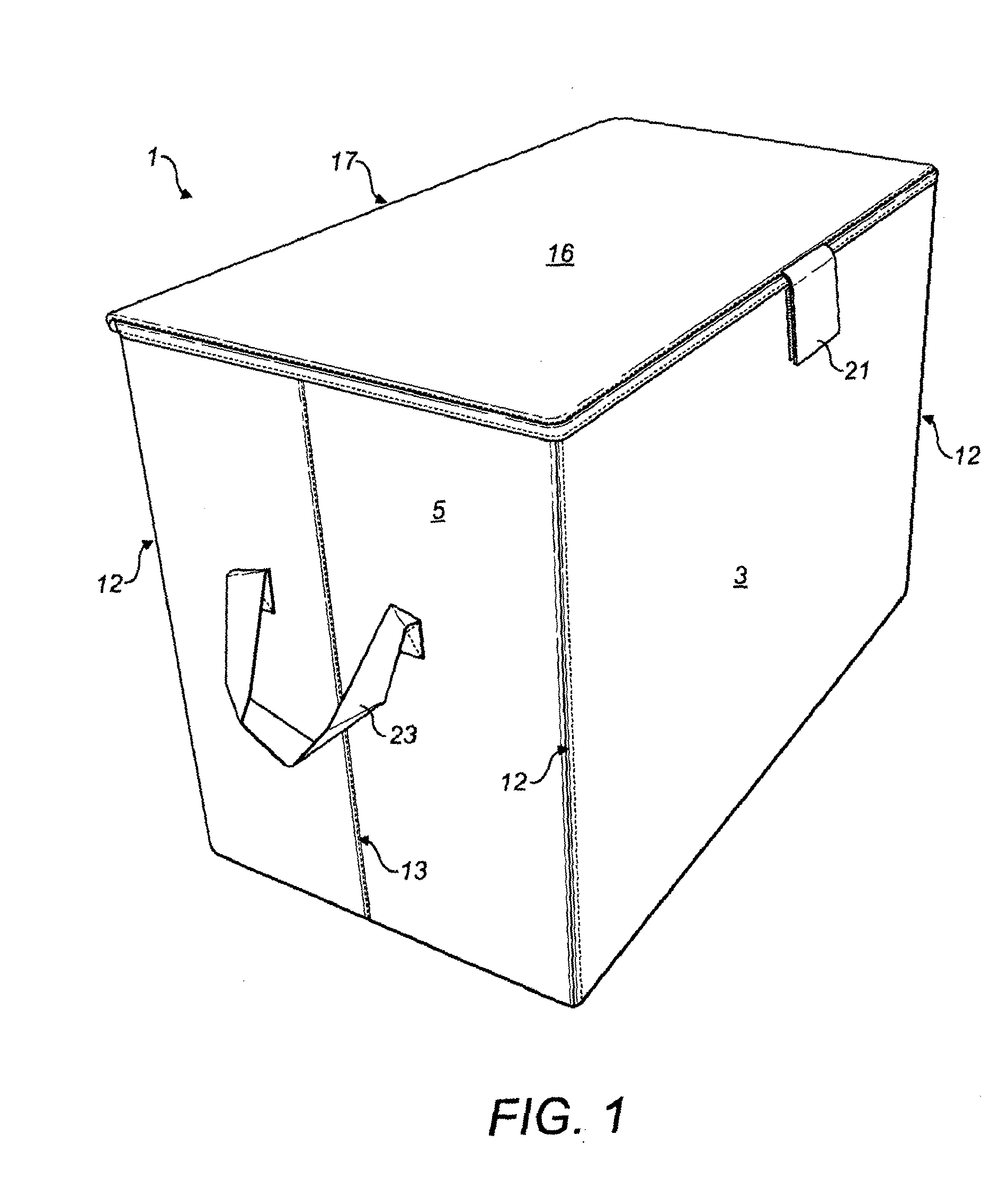

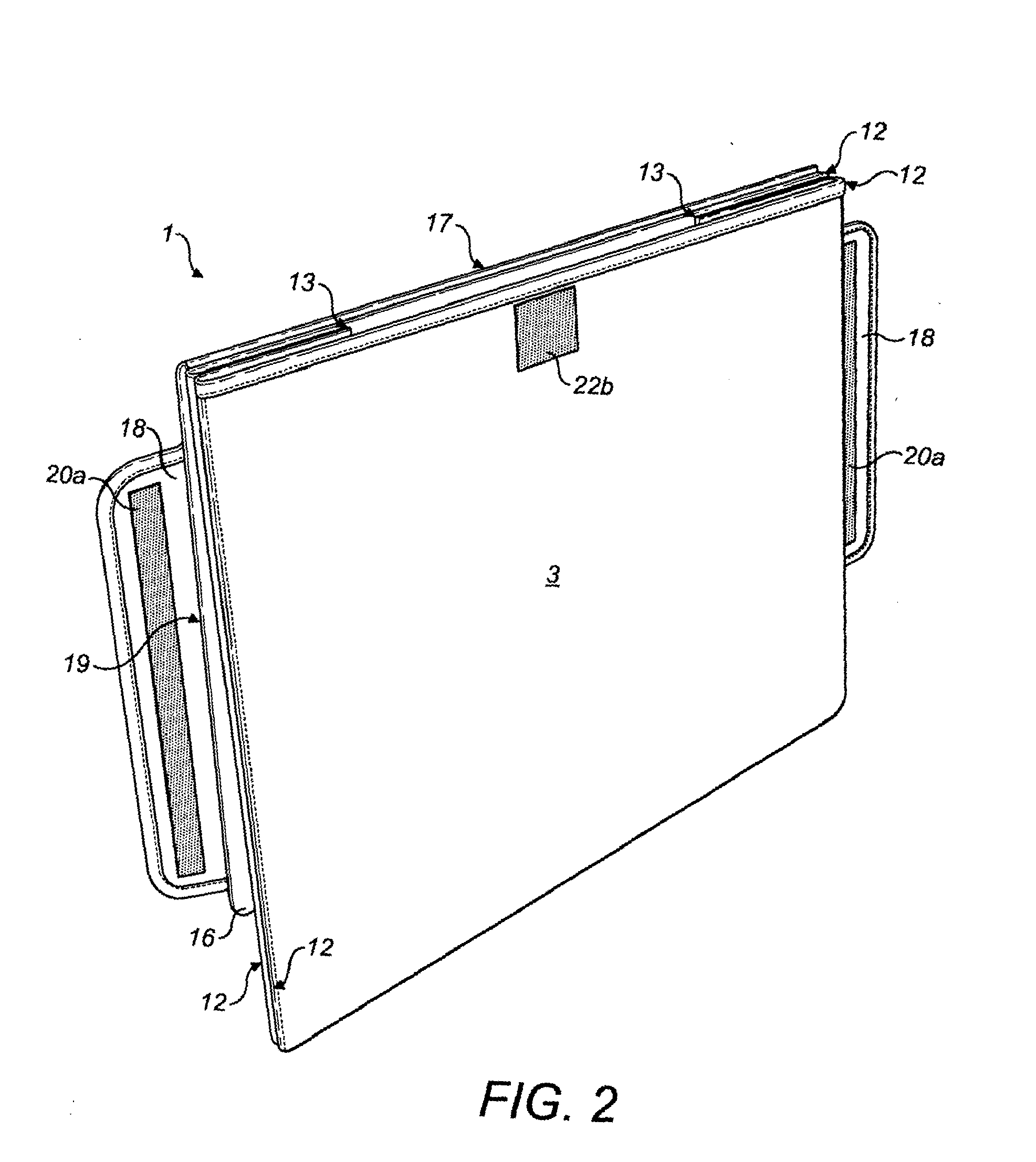

[0043]With reference to FIGS. 1 to 6 and particularly FIG. 3, a stackable crate according to a first embodiment will now be described. Thereafter, a second embodiment constructed according to similar principles will be described. The crate 1 comprises a rectangular flexible web base 2, upstanding opposing semi-rigid side walls 3,4 and upstanding opposing semi-rigid end walls 5,6. The side walls 3,4 have a sandwich construction of a semi-rigid panel 7 between flexible webs 8, 9. The end walls have a sandwich construction of two semi-rigid panels 10 between flexible webs 11, 12. The construction of these walls will be further described with reference to FIG. 6.

[0044]The base flexible web 2 is stitched to the flexible webs of each of the side and end walls 3,4,5,6 so creating a seam at each juncture. The flexible webs of the side walls 3,4 are stitched to the flexible webs of the adjacent end walls 5,6, again forming a seam at each juncture. Upstanding hinges 12 are therefore formed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com