Delivery unit

a technology of delivery unit and delivery head, which is applied in the direction of machines/engines, transportation and packaging, liquid fuel engines, etc., can solve the problems of hydraulic loss, unfavorable energy terms, and high cost of rotational speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

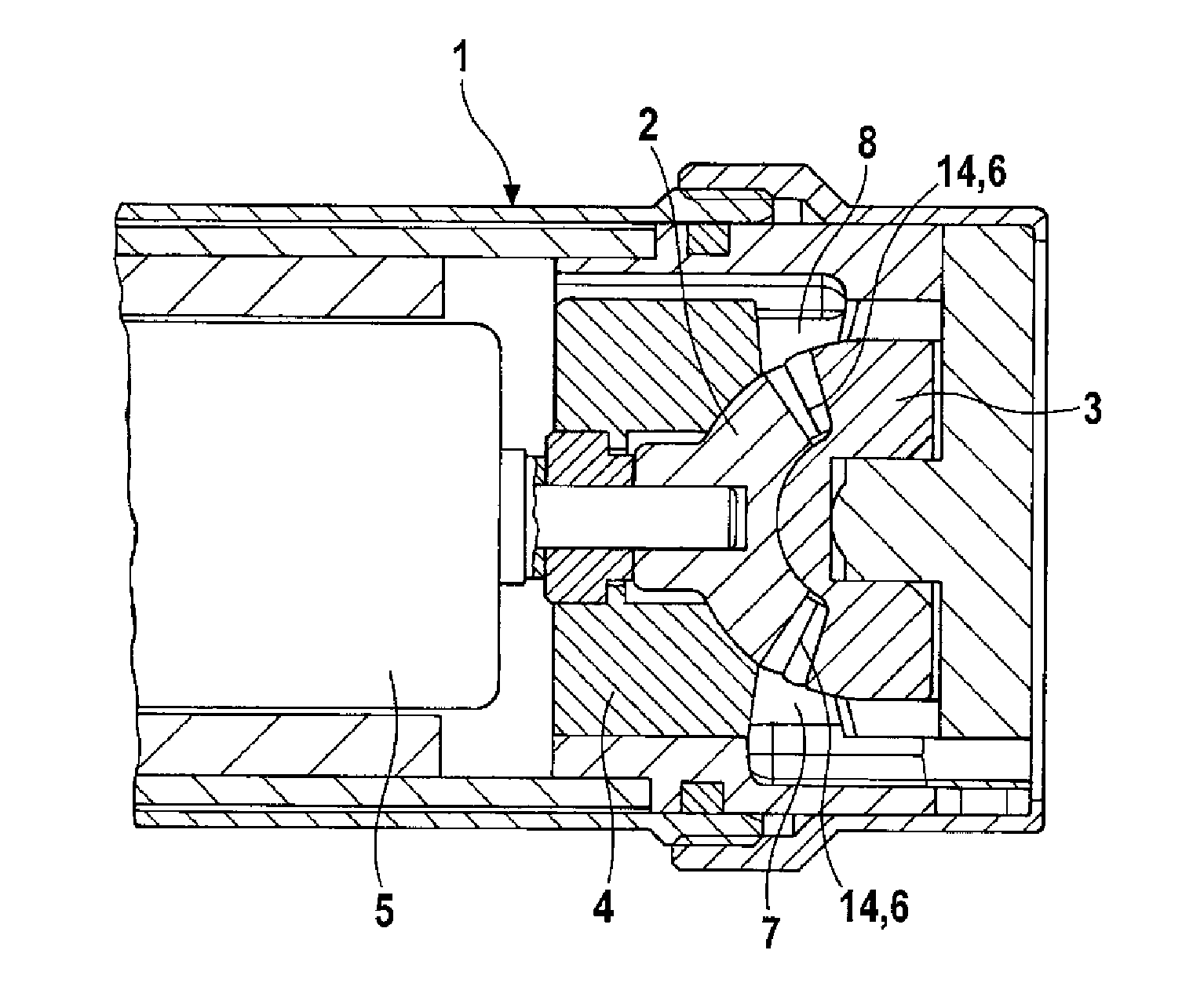

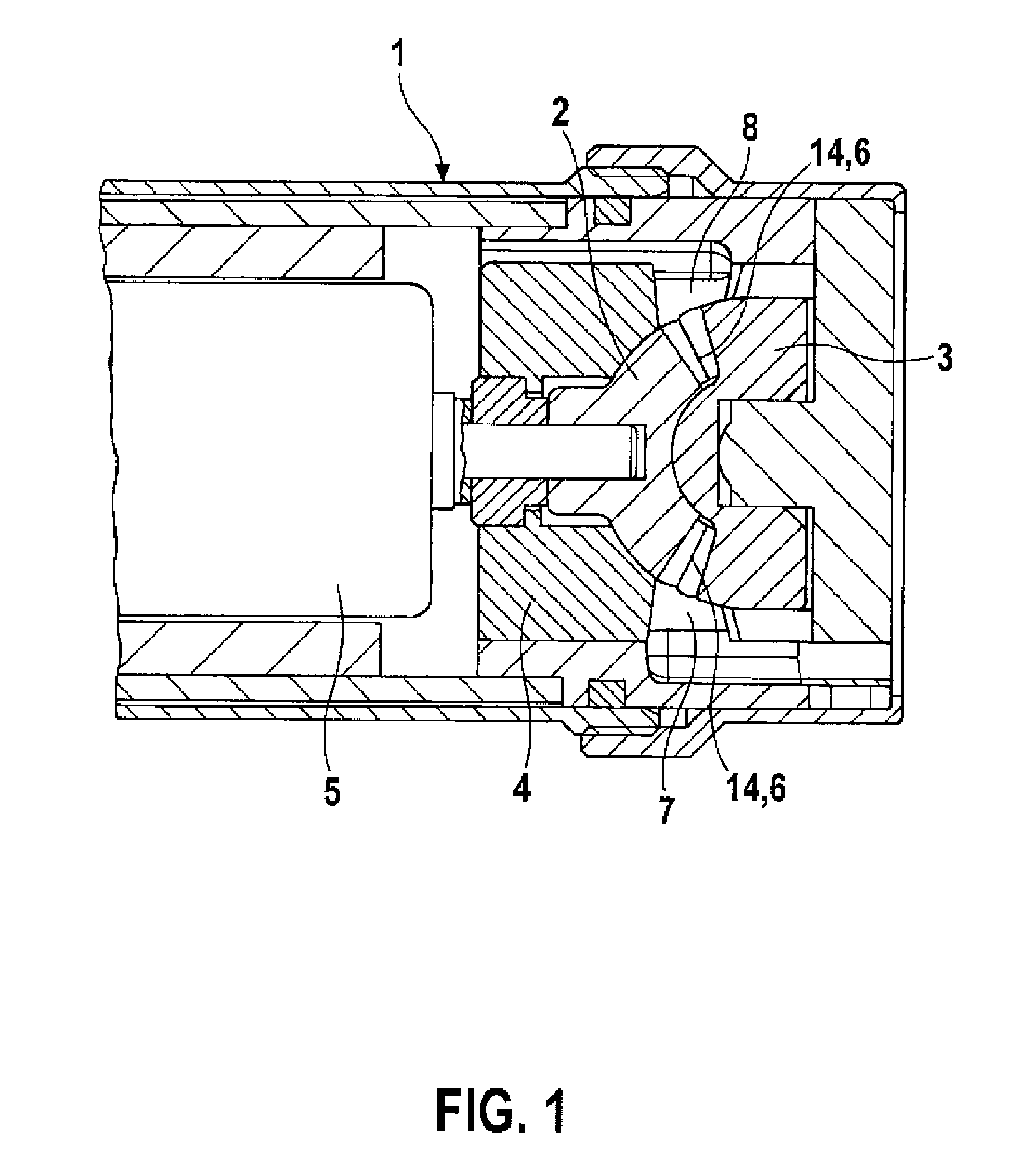

[0011]FIG. 1 shows in section a delivery unit to which the invention could be applied.

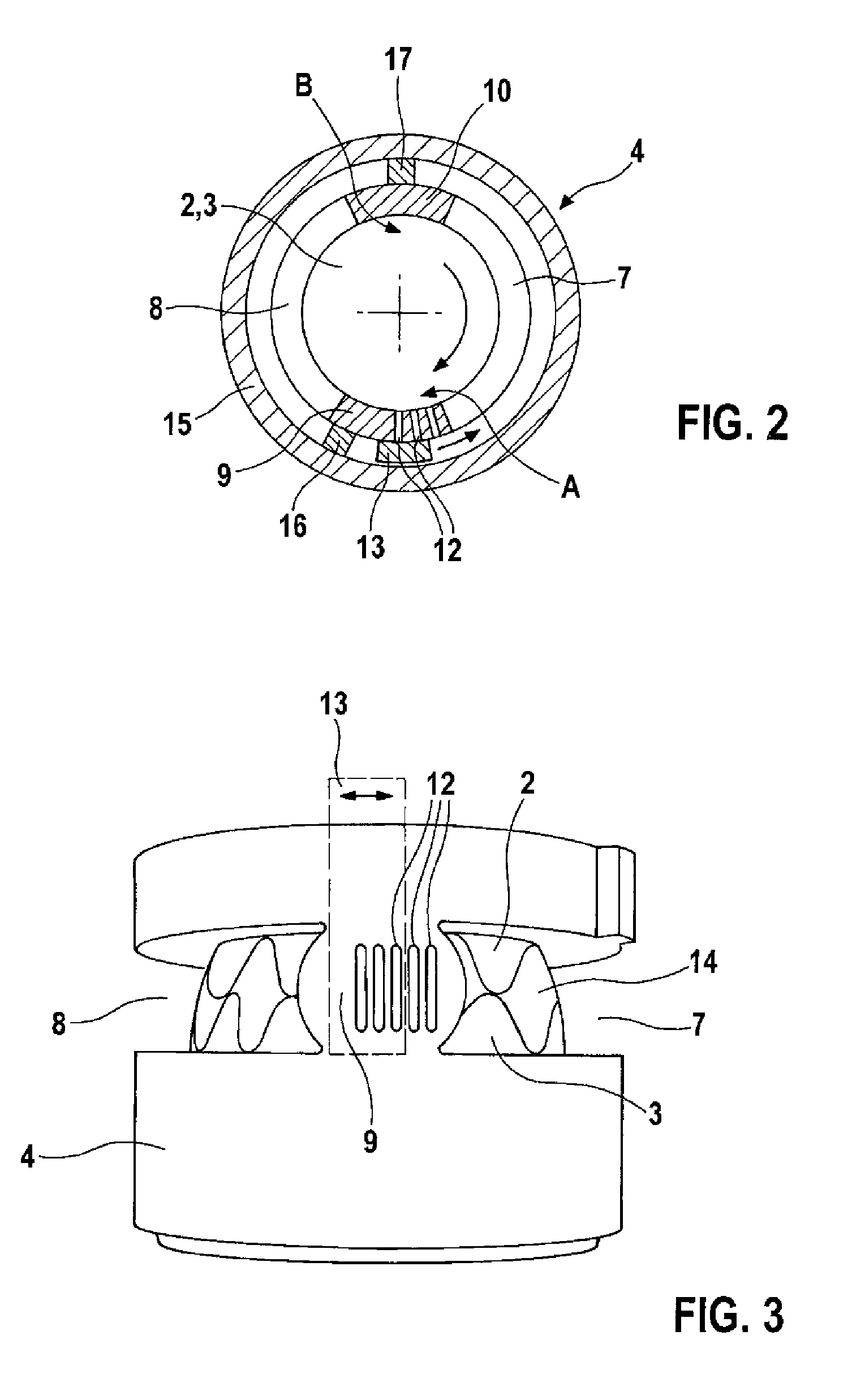

[0012]The delivery unit 1 has a drive rotor 2 and an output rotor 3 driven by the drive rotor 2 which are both mounted in a rotor housing 4. The drive rotor 2 is driven by a motor 5, for example an electric motor, via a driveshaft. The two rotors 2, 3 each have a spur toothing6, for example a cycloidal spur toothing, which interact with each other in a meshing manner and draw fluid in through at least one inlet 7 in the rotor housing 4 and push said liquid out through an outlet 8 in the rotor housing 4 following the positive displacement principle. Working chambers 14 are formed between the spur toothings 6 of the rotors 2, 3. The axes of rotation of the two rotors 2, 3 extend obliquely to each other and thus enclose an angle other than 180 degrees so that the volume of the working chambers 14 alternately increases and decreases during a revolution of the drive rotor 2. At the inlet 7 the volume of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com