Reclosable bag with tear open feature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

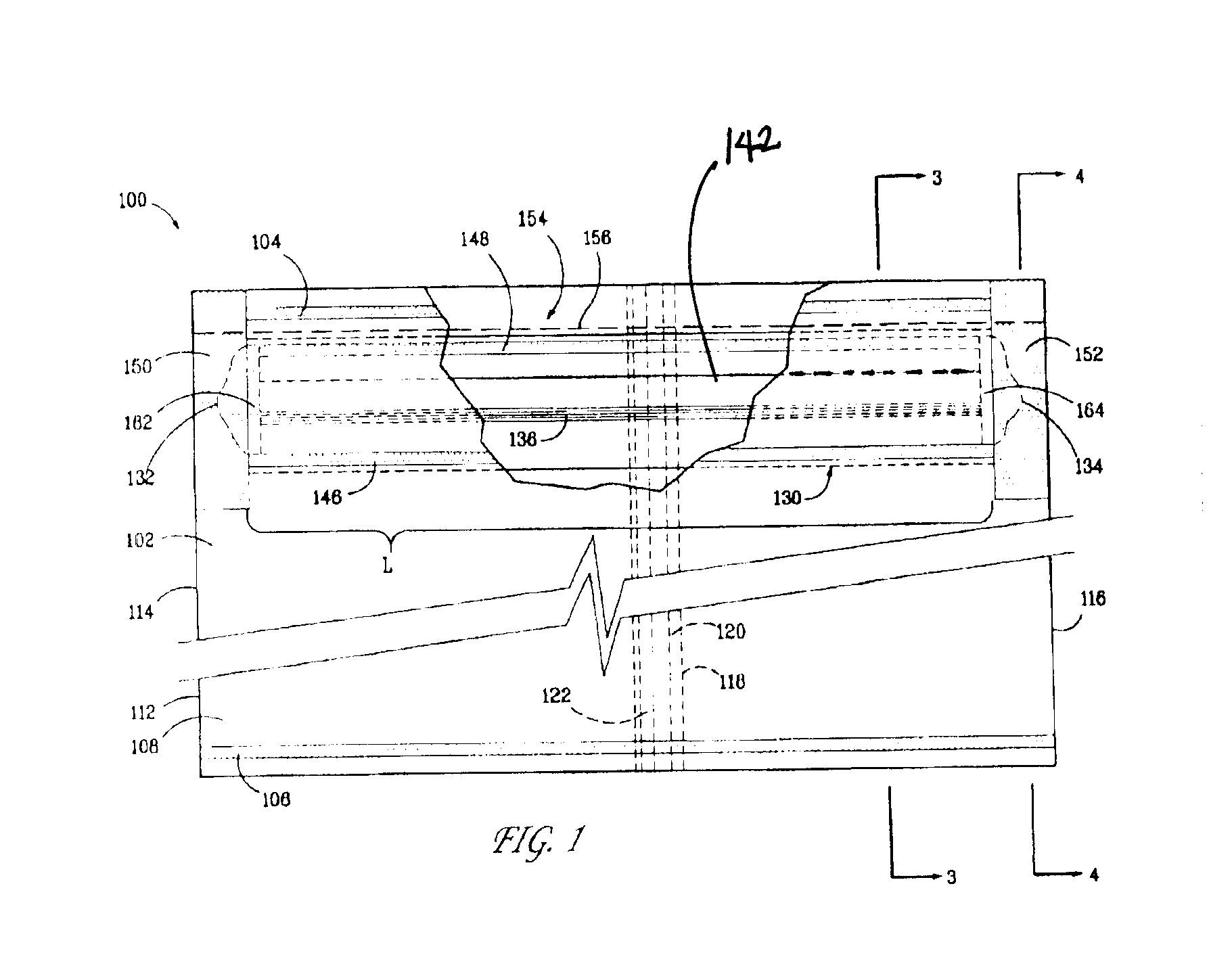

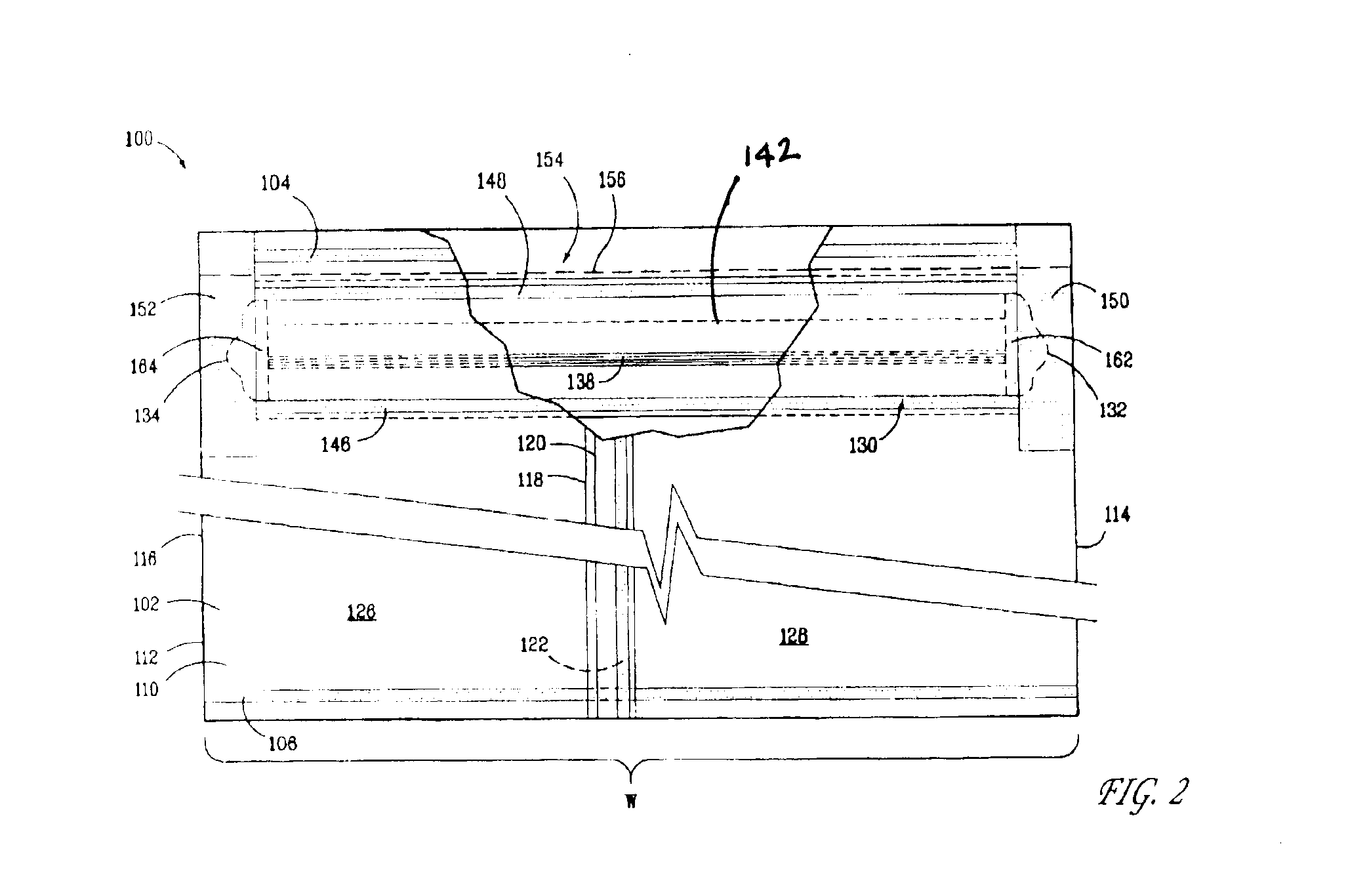

[0036]FIG. 1 is a front plan view of reclosable back-seam bag 100. Reclosable back-seam bag 100 includes a bag body 102. Bag body 102 (FIGS. 1-4) can include a top seal 104 and a bottom seal 106, and a front wall 108 and a back wall 110. Front wall 108 (FIGS. 1, 3 and 4) may be joined to the back wall 110 at the top seal 104 and the bottom seal 106 (FIGS. 1-4). It is appreciated that bag body 102 can be formed on conventional form fill and seal machines known in the art. In another embodiment, a reclosable bag can be configured as a side-seam bag having one web of film folded along a longitudinal fold to form two half webs of film, and having top edges of each of the two half webs of film sealed together to form a side seam. In another embodiment, the reclosable bag is configured as having two webs of film that are sealed together along respective edges of the two webs of film to form four side seams, each of the two webs of film having an inside surface, and the back wall having tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com