Inertial igniters with safety pin for initiation with low setback acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

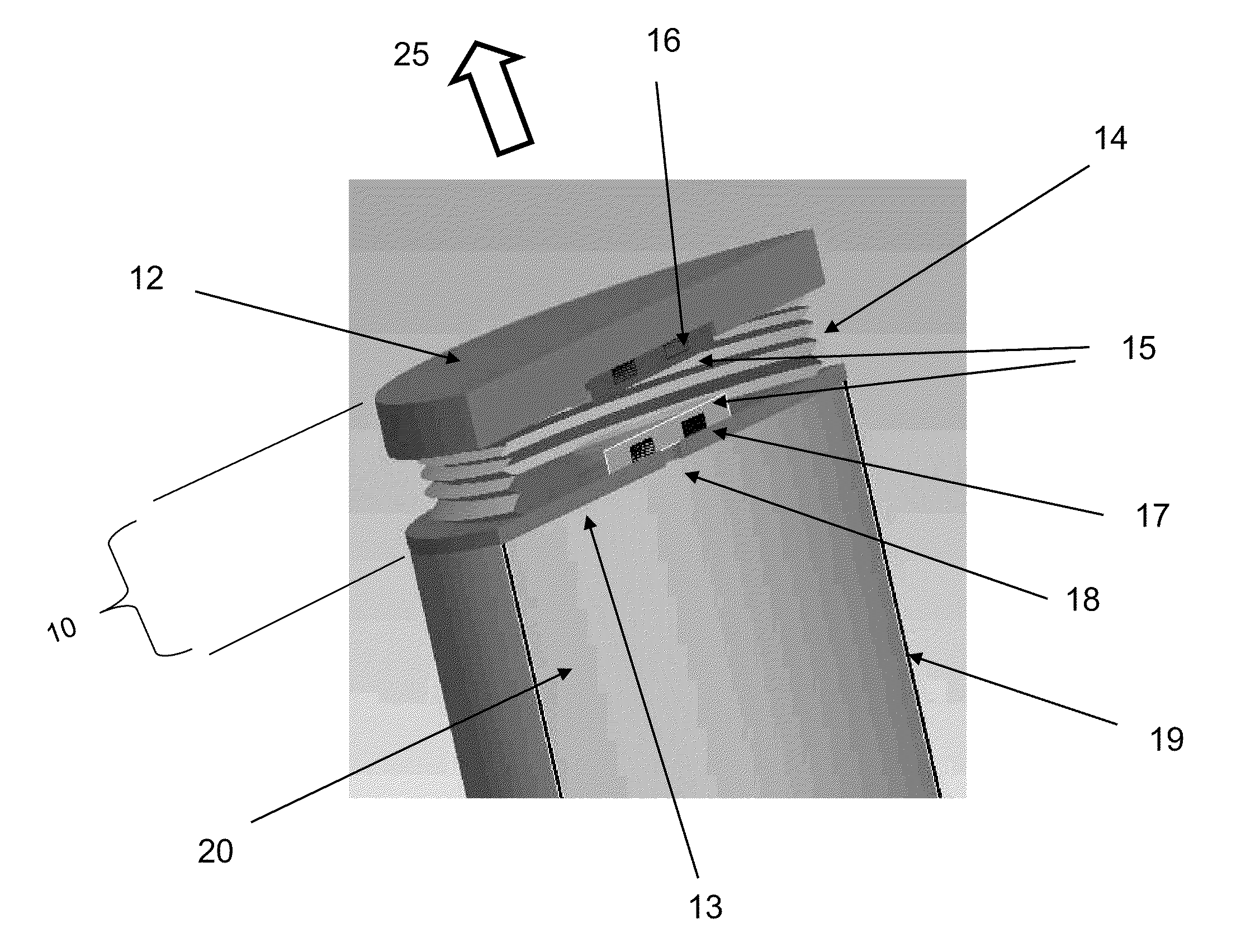

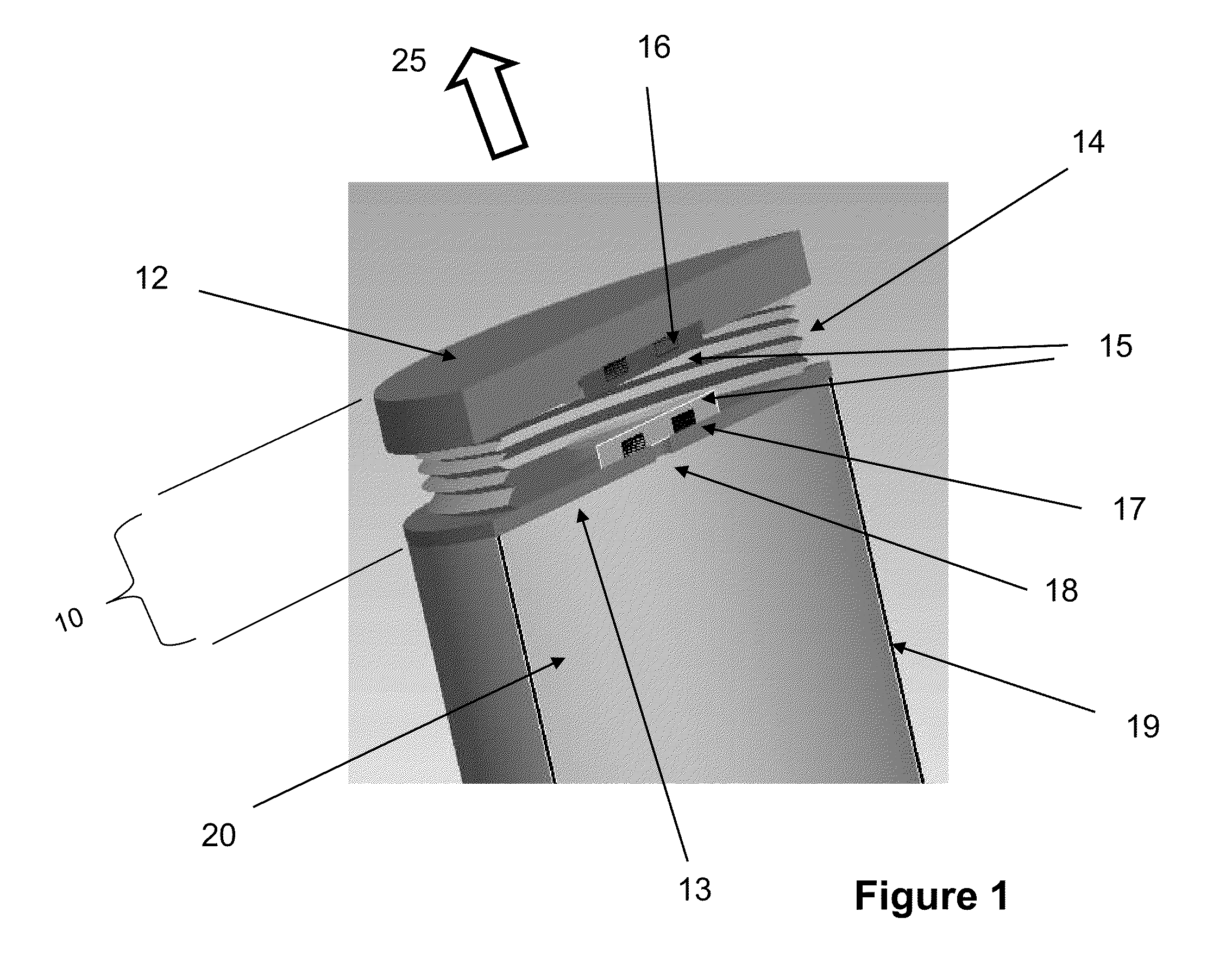

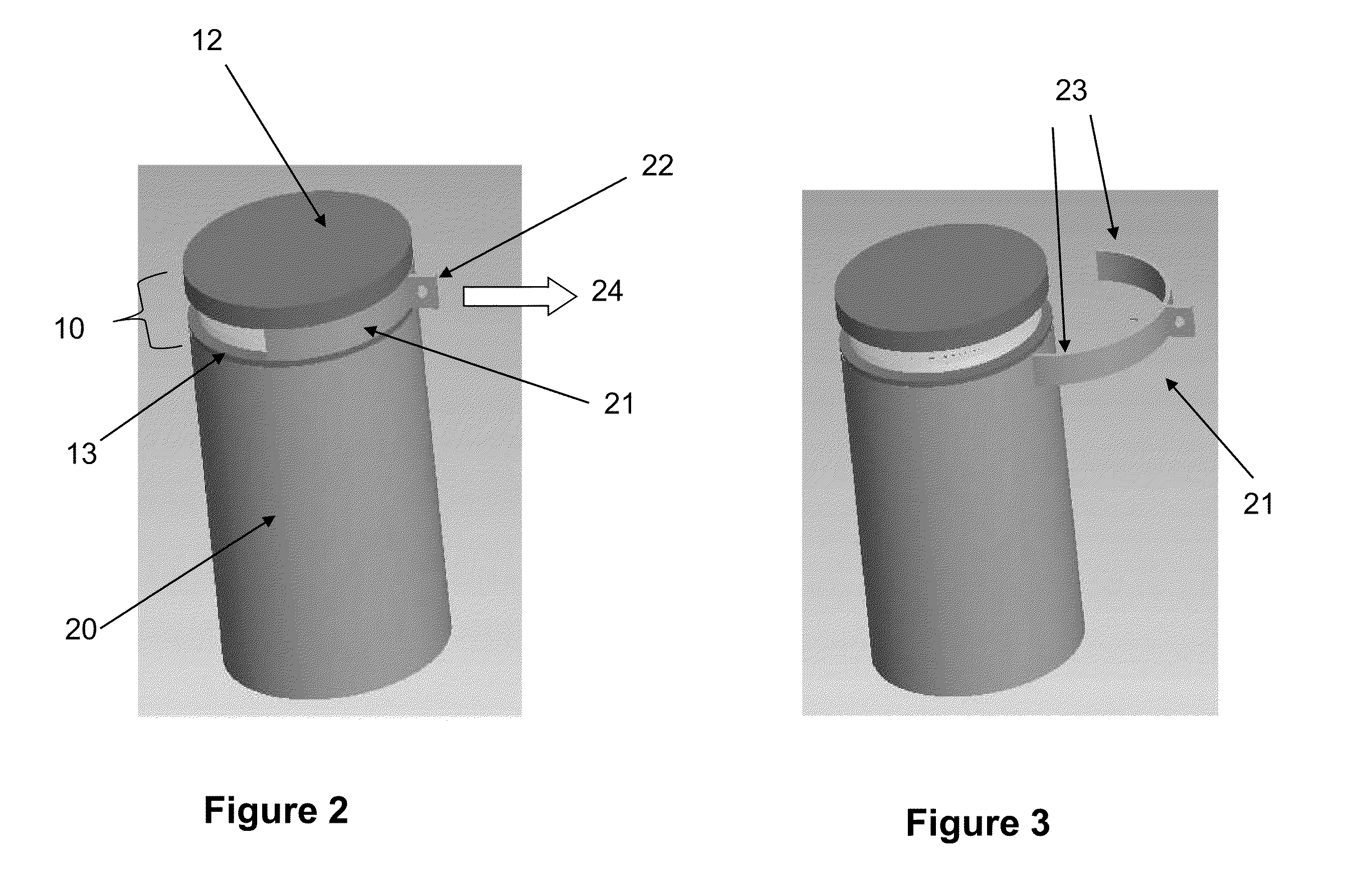

[0025]The schematic of a first embodiment is shown in the frontal cross-sectional view of FIG. 1. In FIG. 1, the inertial igniter 10 is shown to be fixed to the top of the thermal battery 11. The inertial igniter 10 is shown to consist of a top cap 12, which also acts as a striker mass for initiating ignition during all-fire conditions. The top cap 12 is attached (such as being welded or brazed) to the base plate 13 by a bellow 14, which can be stainless steel or other suitable material. The base plate 13 can be the top cap of the thermal battery 20 and is attached (such as being welded or brazed) to the thermal battery housing 19. The base plate 13 can be fabricated with stainless steel. The top cap 12 can be made out of a one piece stainless steel material. The top cap 12 may also be constructed with two piece elements (not shown in FIG. 1), with an outer shell of stainless steel (to make it easier to weld to the bellow 14) and an interior (in the present design disc shaped) eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com