Control device for an automated geared transmission

a control device and gear shift technology, applied in mechanical equipment, propulsion parts, transportation and packaging, etc., can solve the problem of not being able to simultaneously supply the supply output, and achieve the effect of reducing the supply output and preventing the supply pressure from increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

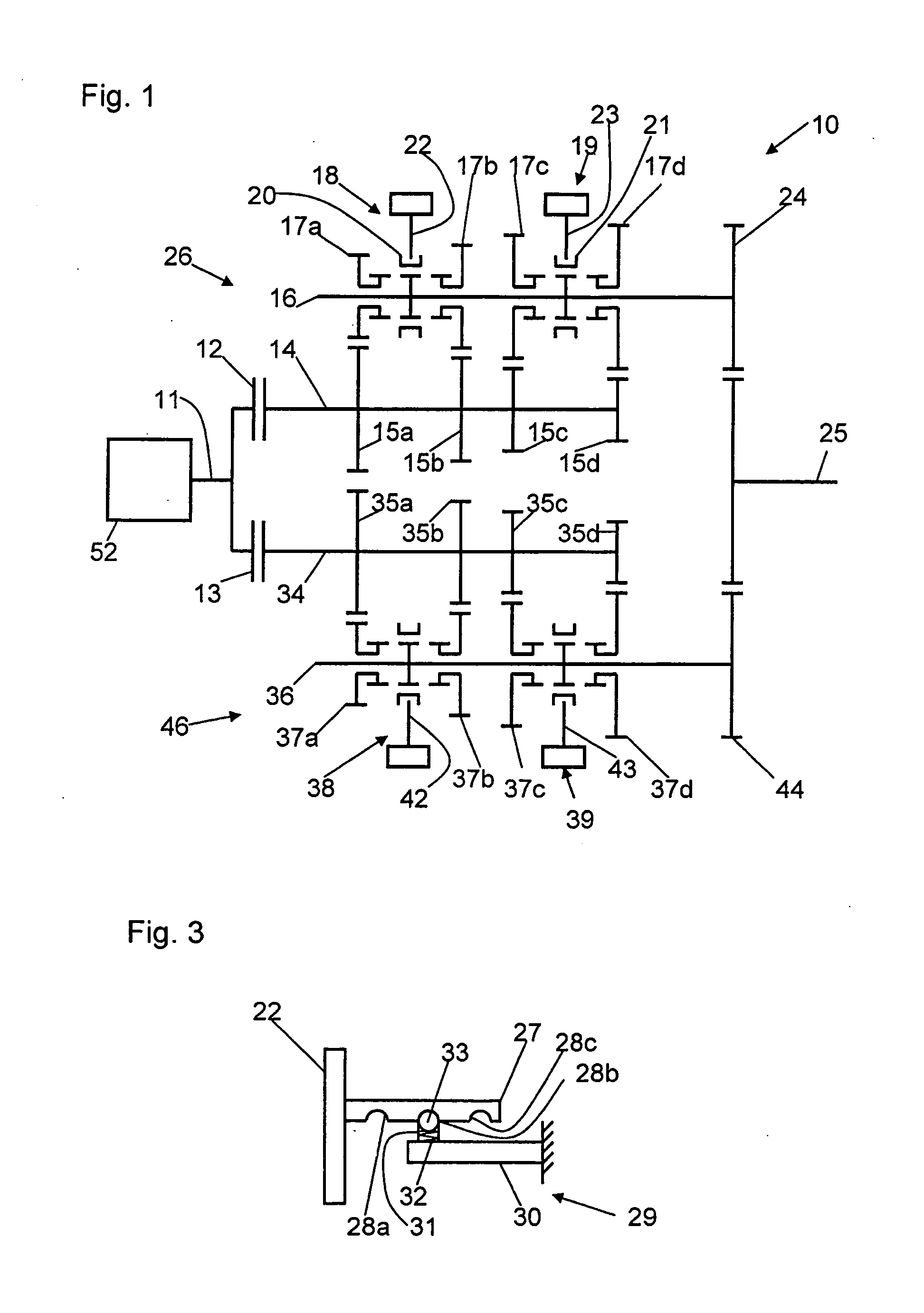

[0031]FIG. 1 shows an automated transmission in the form of a dual clutch transmission 10 for a motor vehicle with seven forward and one reverse gear which is connected via a drive shaft 11 to a drive machine 52, for example an internal combustion engine. The drive shaft 11 is in operative connection with a first and a second clutch 12, 13. The clutches 12, 13 serve as start-up clutches and are particularly designed as wet friction clutches, which can be actuated hydraulically. The first clutch 12 is additionally in operative connection with a first transmission input shaft 14, on which are arranged four fixed wheels 15a to 15d. A first countershaft 16 is arranged parallel to the first transmission input shaft 14, on which countershaft are mounted four idler wheels 17a to 17d in a rotatable manner, which, respectively, cog with the fixed wheels 15a to 15d of the first transmission input shaft 14. The idler wheels 17a, 17b can be coupled to the countershaft 16 in a rotationally fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com