Helmet

a helmet and helmet technology, applied in the field of helmets, to achieve the effect of absorbing more shock energy, preventing or reducing the bouncing of the helmet against the hit surface, and improving the protection against penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

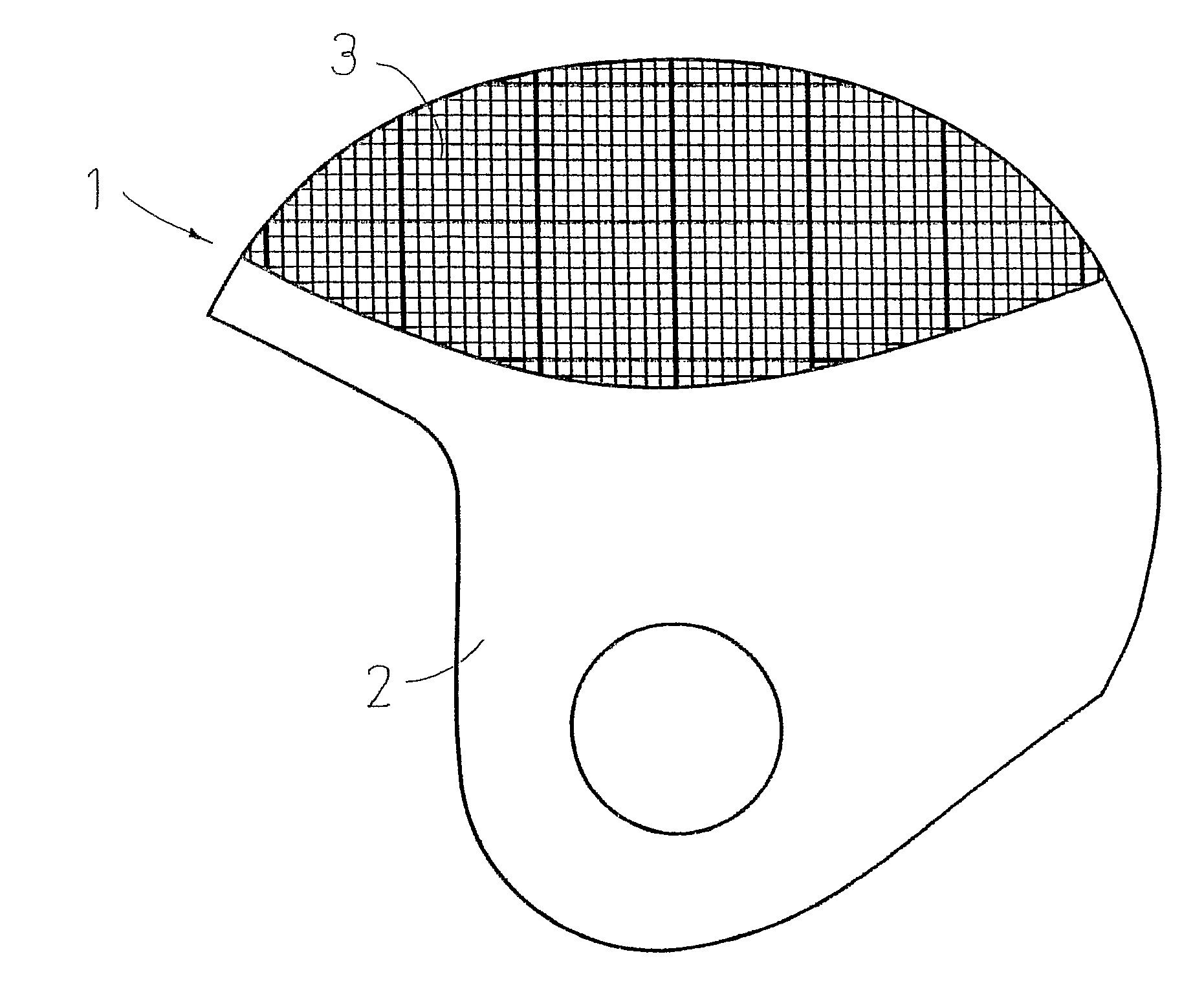

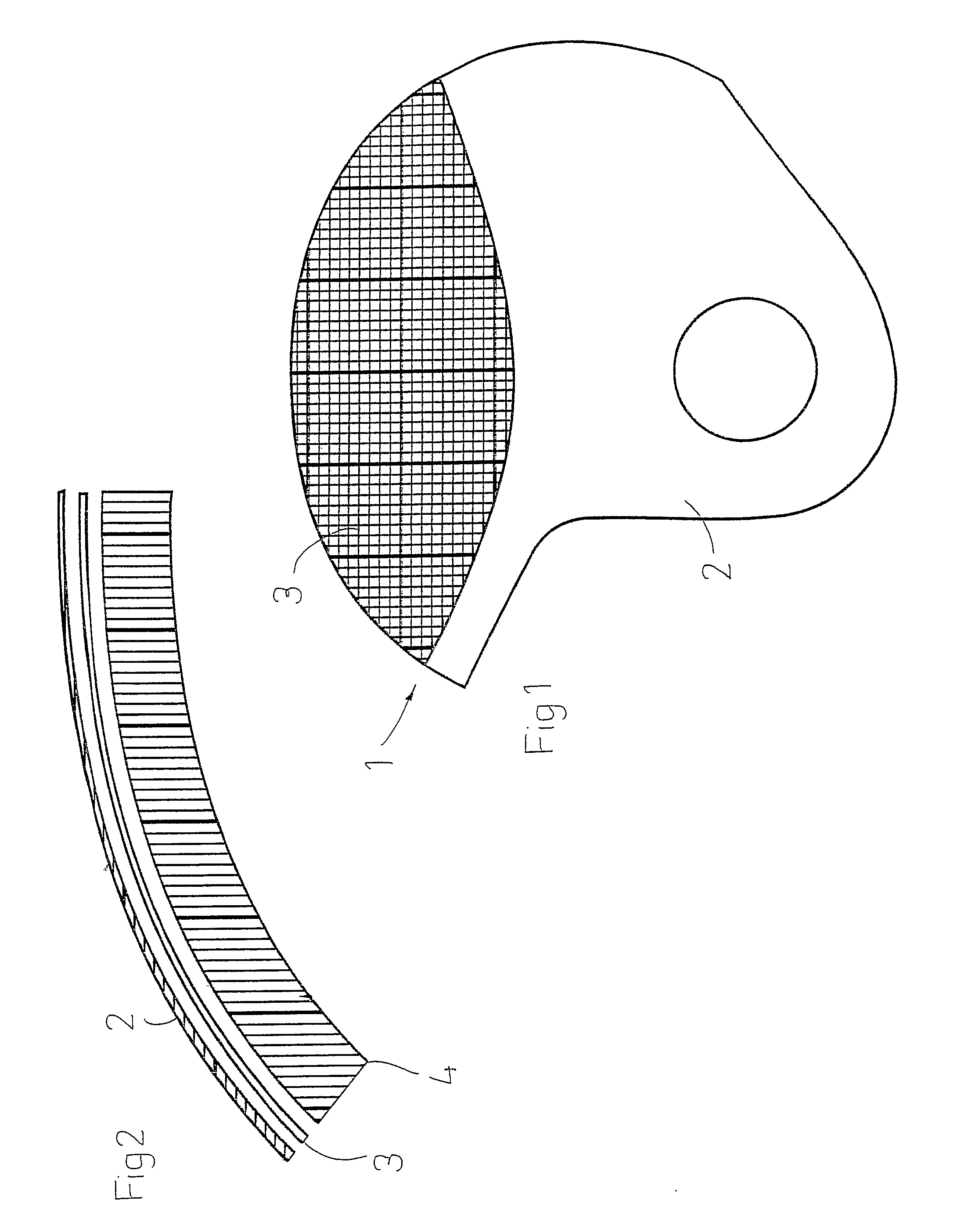

[0013]According to FIG. 1 a helmet 1 of the present invention is shown where a portion of a rigid outer shell 2 is taken away so that a coated net, woven or nonwoven material 3 is visible. The helmet 1 comprises at least a rigid outer shell 2 and an inner portion of energy absorbing material 4. The outer shell 2 may comprise more than one layer, for example an outer polycarbonate layer and an inner glass fibre reinforced resin layer. Also the inner portion of energy absorbing material 4 may comprise more than one layer, for example a layer of honeycomb material, a layer of expanded polystyrene and a layer of soft foamed plastic.

[0014]At least a portion, preferably the upper portion, of the rigid outer shell is made up with a thin material layer having a thickness of 0.01-4 mm, preferably 0.1-1.0 mm, for example a rigid outer shell 2 of ABS, polycarbonate, lexan or alike may be used. Other materials are also conceivable.

[0015]Between the outer shell 2 and the inner portion of energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com