Female armor system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

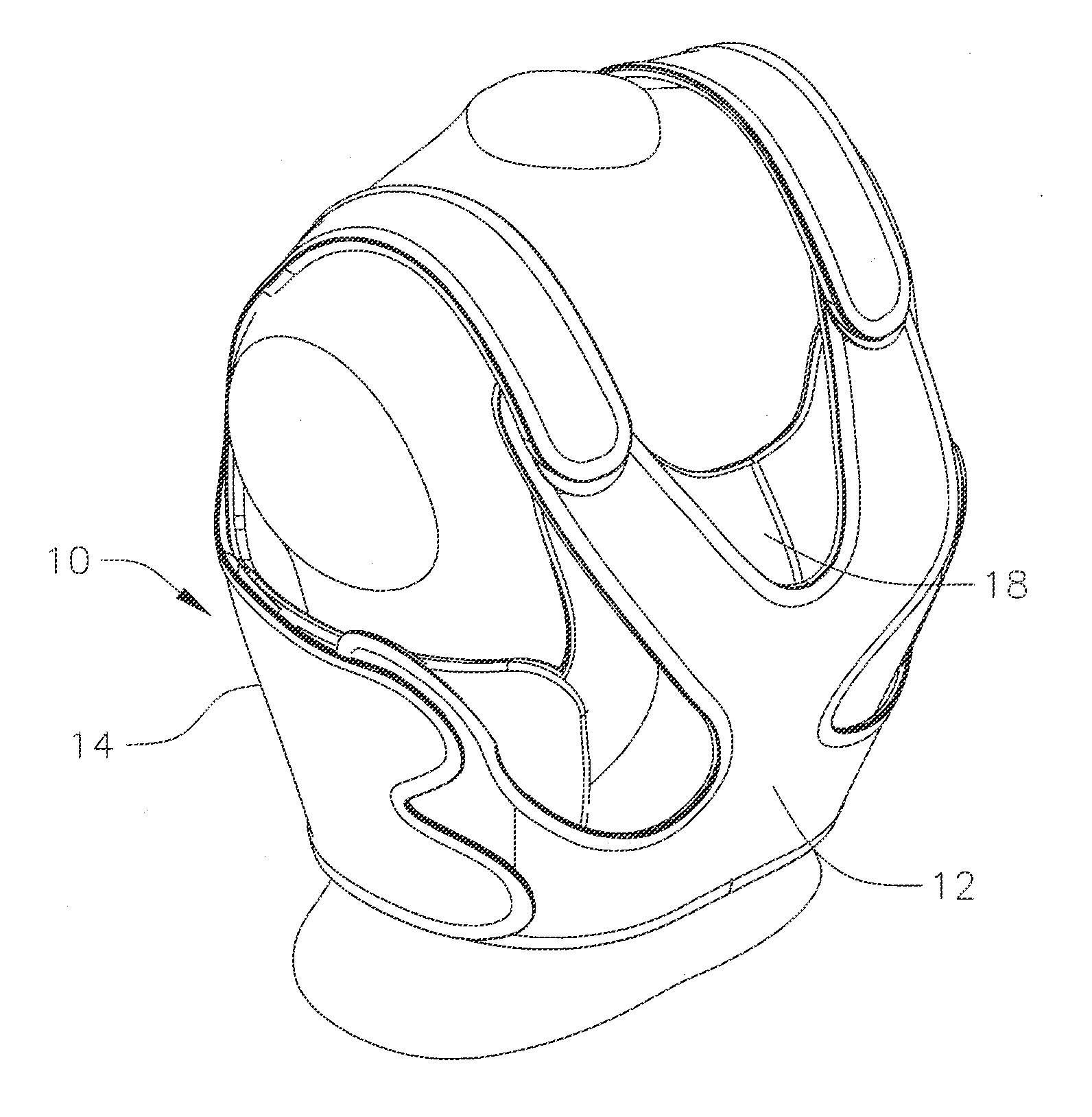

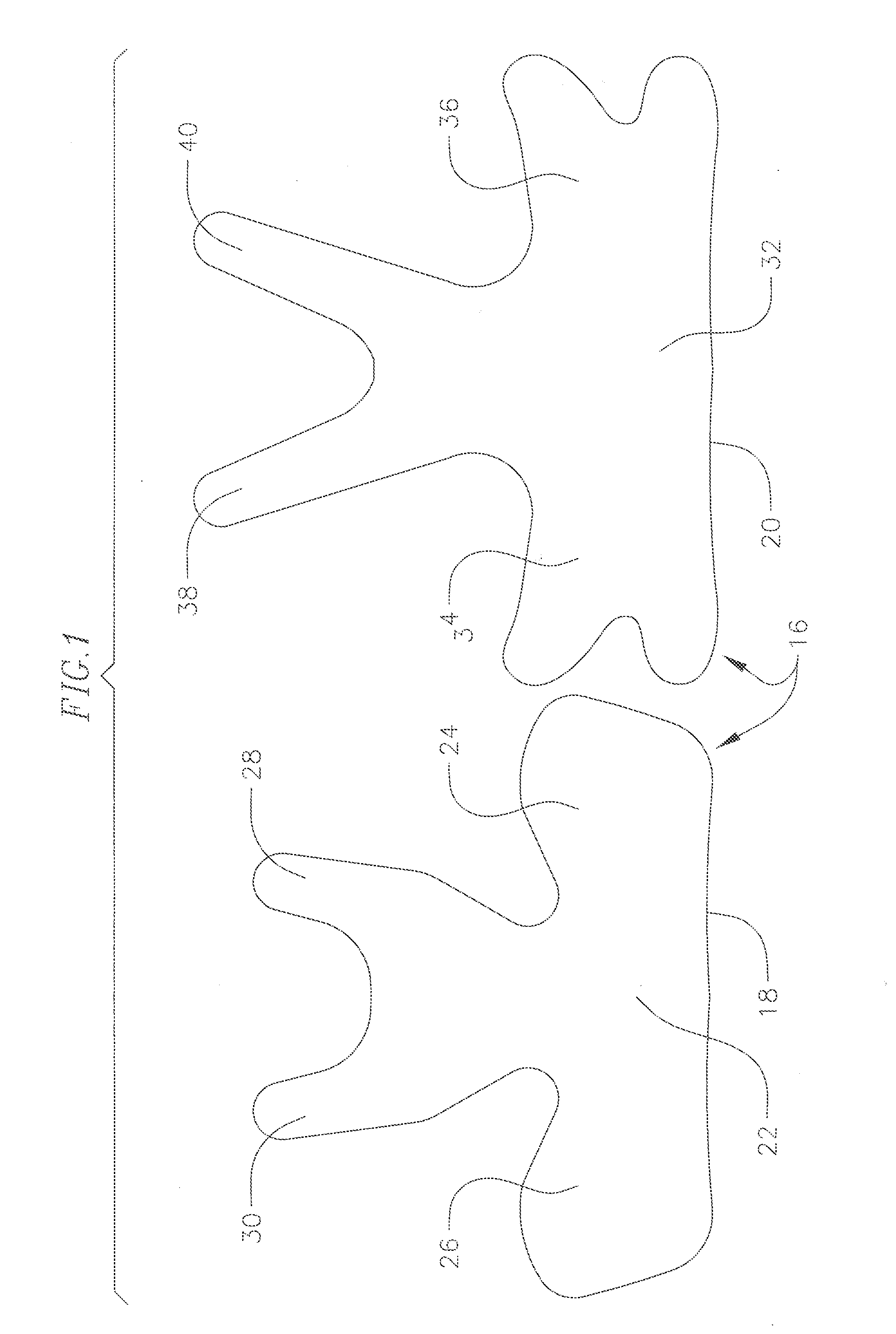

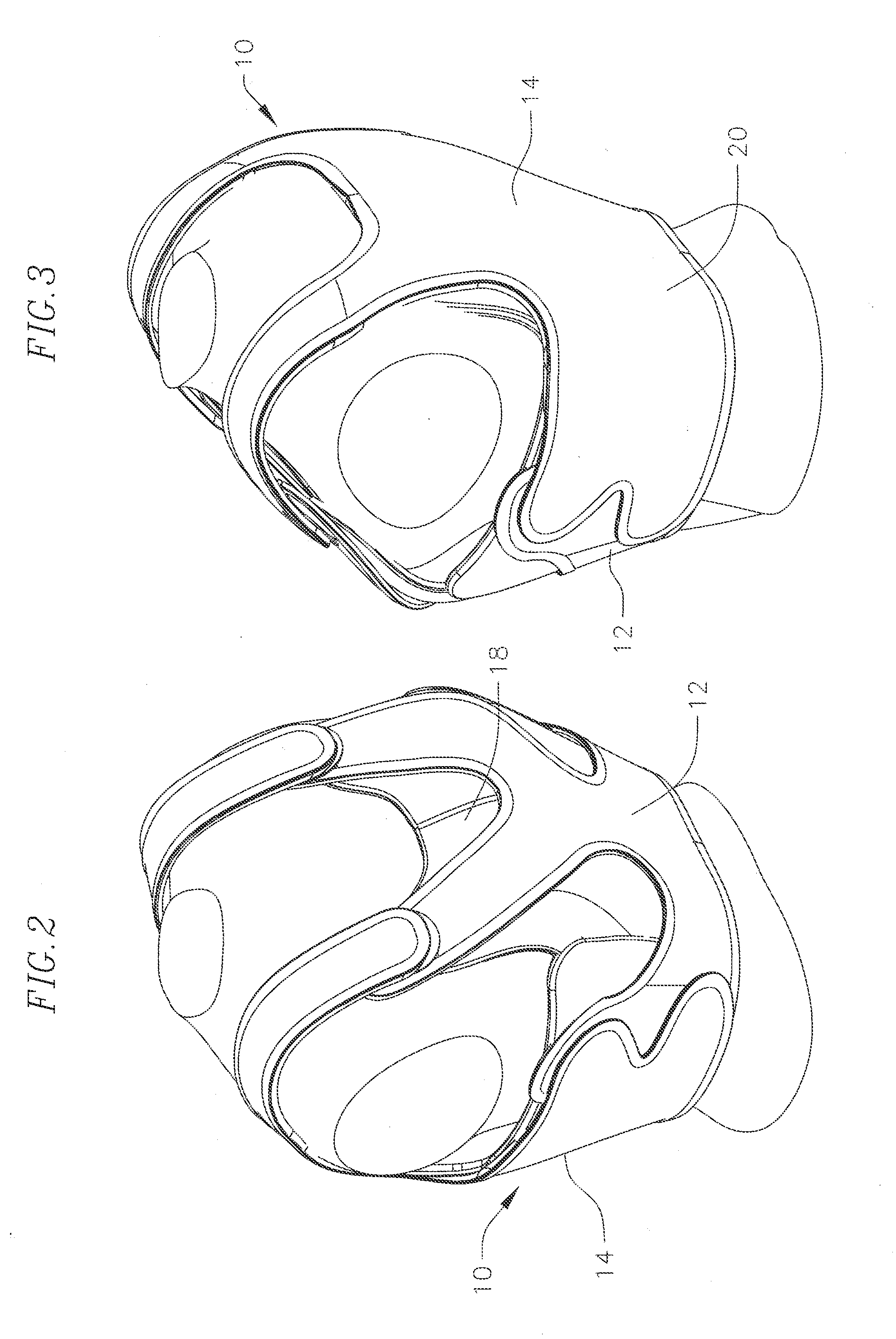

[0017]The ballistic vest 10 of the present invention is shown in FIGS. 2 and 3. The ballistic vest 10 is a concealable vest of the soft body armor type commonly worn by law enforcement officers. The ballistic vest includes a front panel 12 and a rear panel 14. The front panel 12 protects the chest and stomach of the wearer while the rear panel 14 protects the back and sides of the wearer, as will be discussed in more detail below. The front panel 12 and the rear panel 14 are held in position on the wearer by a stretchable supportive outer garment 16 as also shown in more detail in FIG. 1. The supportive outer garment includes a front section 18 and a rear section 20 wherein the front section 18 is positioned over front panel 12 and the rear section 20 is positioned over the back panel 14 to conform the ballistic panels to the body of the wearer. Alternatively, the stretchable outer garment can be a single piece construction similar to a sports bra.

[0018]The front section 18 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com