Paper laminates comprising tungsten treated titanium dioxide having improved photostability

a technology of titanium dioxide and phototability, which is applied in the field of resinimpregnated, opaque, cellulose pulpbased sheet and paper laminates, can solve the problems of pyrogenically prepared metal oxide particles, process and materials to be added to improve the properties of titanium dioxide particles,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

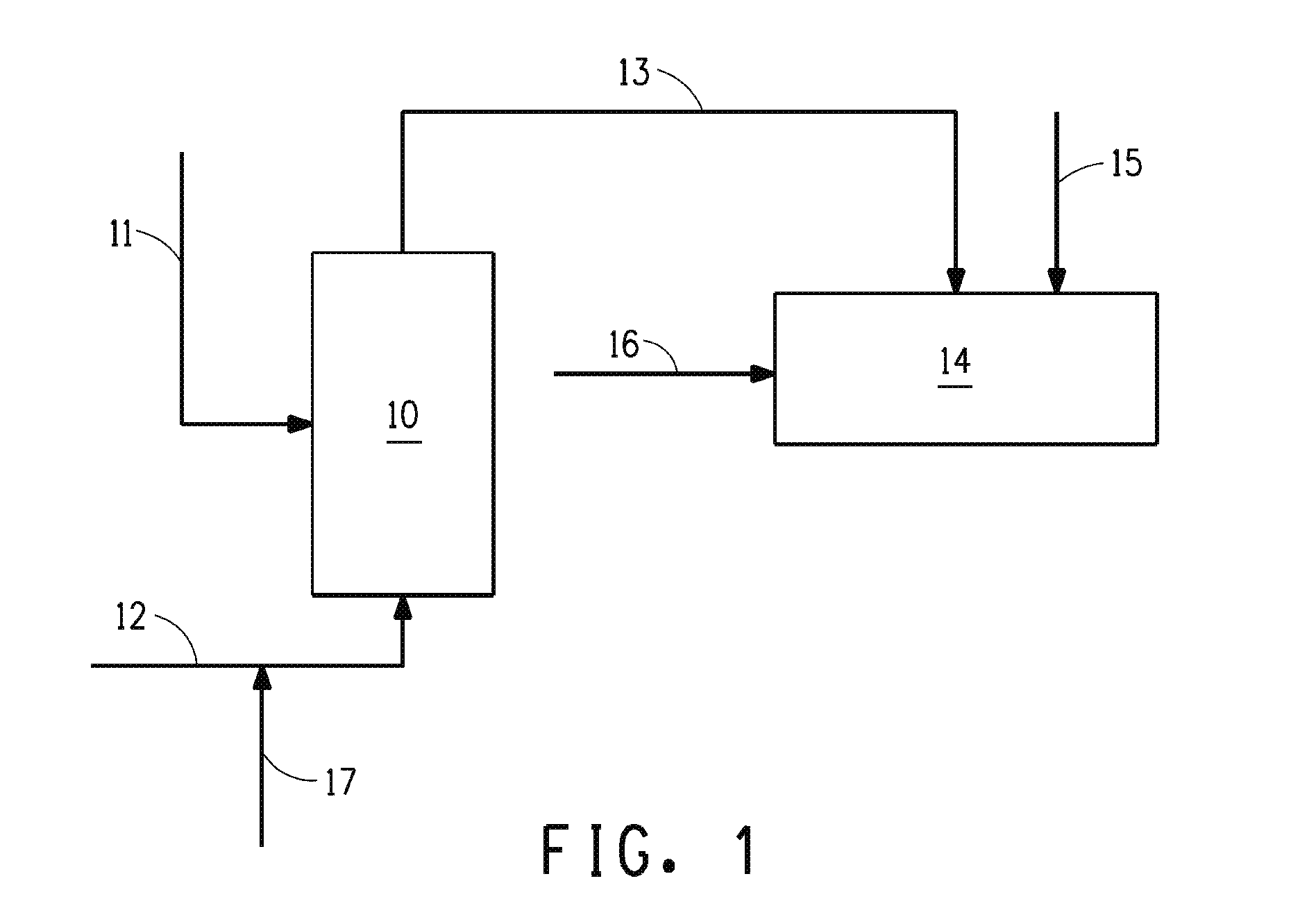

Image

Examples

example 3

[0056]Titanium dioxide similar to that described in Comparative Example 1 was well mixed with various amounts of ammonium tungstate, (NH4)10W12O41·5H2O, to give samples having the W contents listed below. These samples were fired as described in Comparative Example 1. After firing the samples had L*a*b* color and photostability ratios (PSR) as given in the following table:

W (wt. %)L*a*b*PSR0.099.15−0.452.171.00.3499.00−0.712.723.01.7298.56−0.823.1710.43.4498.41−0.903.11211.4

[0057]The increased incorporation of W clearly enhanced photostability up to roughly a factor of 200 while the color was only minimally affected.

example 4

[0058]Titanium dioxide similar to that described in Comparative Example 1 was impregnated via incipient wetness with various amounts of ammonium tungstate, (NH4)10W12O41·5H2O, to give samples having the W contents listed below. These samples were fired as described in Comparative Example 1. After firing the samples had L*a*b* color and photostability ratios as given in the following table:

W (wt. %)L*a*b*PSR0.098.160.022.091.00.3497.97−0.022.532.21.7297.52−0.152.7910.03.4497.41−0.533.3467.4

[0059]The increased incorporation of W clearly enhanced photostability up to roughly a factor of 67 while the color index was only minimally affected.

example 5

[0060]Titanium dioxide similar to that described in Comparative Example 2 was well mixed with amounts of ammonium tungstate, (NH4)10W12O41·5H2O, to give samples having the W contents listed below. These samples were fired as described in Comparative Example 1. After firing the samples had L*a*b* color and photostability ratios as given in the following table:

W (wt. %)WL*a*b*PSR0.00.097.71−0.031.891.00.341x97.73−0.212.194.31.725x97.18−0.561.94139.03.4410x 97.03−0.832.45113.8

[0061]The increased incorporation of W clearly enhanced photostability up to roughly a factor of 140 while the color index was only minimally affected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com