High temperature electrolyzer (HTE) including a plurality of cells, having improved operation in the event of breakage of at least one cell and during ageing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

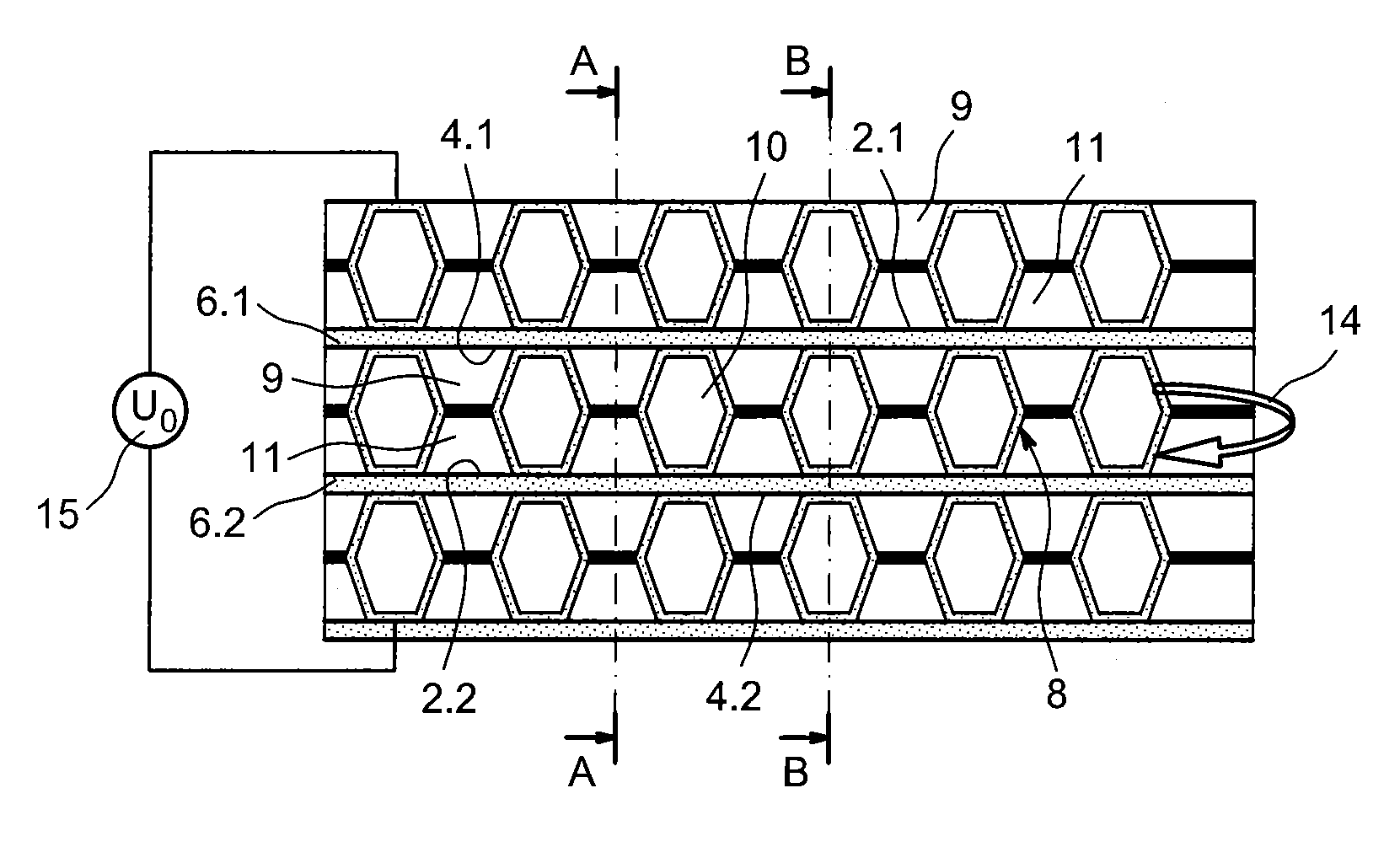

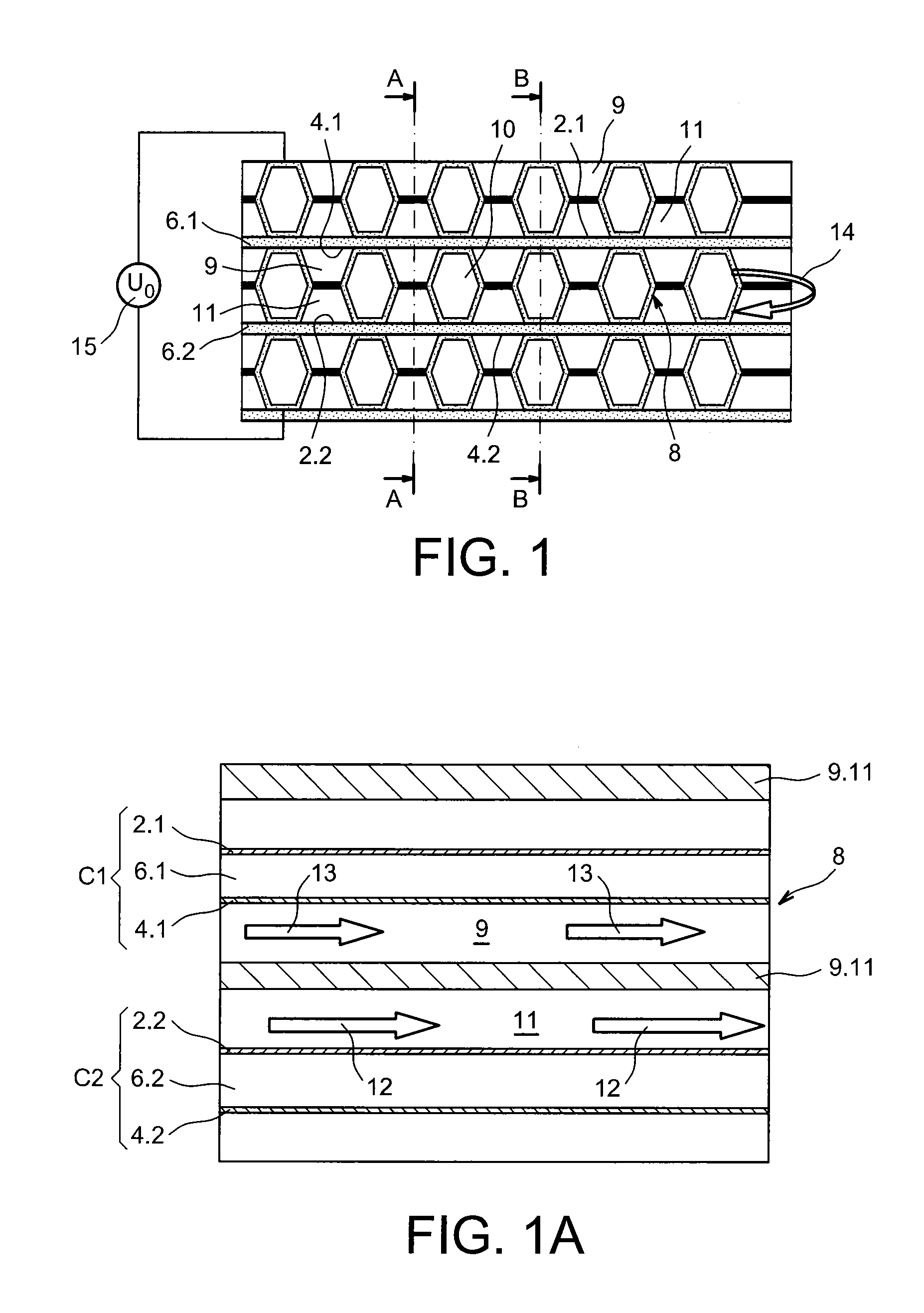

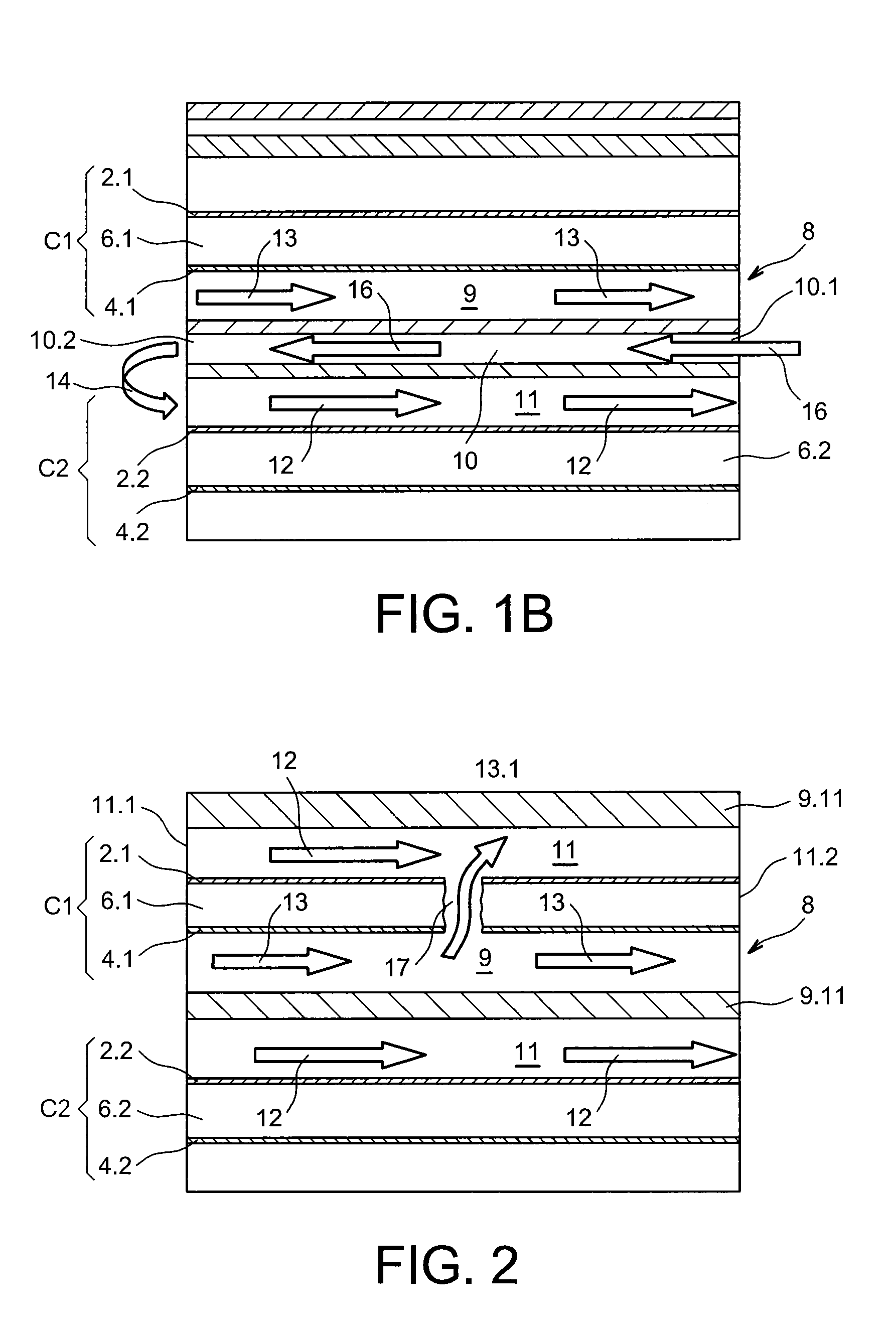

[0016]To do this, the invention relates to a process of electrolyzing water at high temperatures implemented by an electrochemical reactor comprising a stack of N elementary electrochemical cells each formed of a cathode, an anode and an electrolyte inserted between the cathode and the anode, at least one interconnecting plate being arranged between two adjacent elementary cells and in electrical contact with an electrode of one of the two elementary cells and an electrode of the other of the two elementary cells, in which at least water vapour is made to circulate in contact with the cathode and a leaching gas is made to circulate in contact with the anode to evacuate the oxygen produced, characterised in that the following steps are carried out:

[0017]a / simultaneously circulating the water vapour containing at the most 1% of hydrogen at each cathode and at each anode as a leaching gas, the temperatures of the water vapour at the inlet of each anode and each cathode being lower tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com