Full-face-type helmet windshield prop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

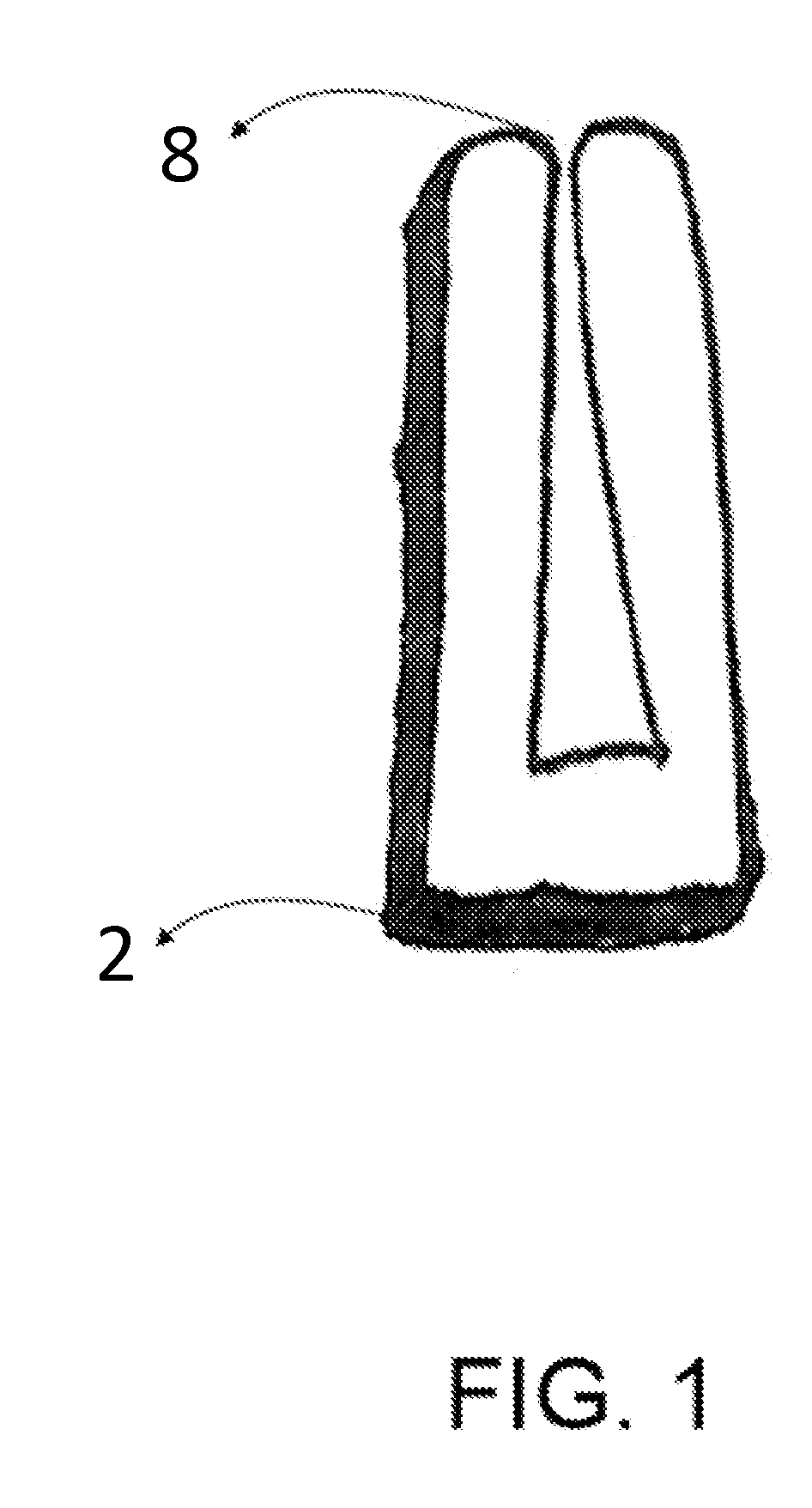

[0011]Referring to FIG. 1 it can be seen that an embodiment of present invention consists of a top area whereby the two sides come together and touch but are not bonded together, like a closed U for example (1). The top area of the propis what affixes it to the full-face-type helmet windshield (1). The bottom of the prop consists of a piece parallel to the ground like the bottom of a U (2). The bottom of the prop is what keeps the full-face-type helmet windshield from completely closing leaving a minimal gap between the chin guard or crown area and the windshield for ventilation and defogging purposes (2).

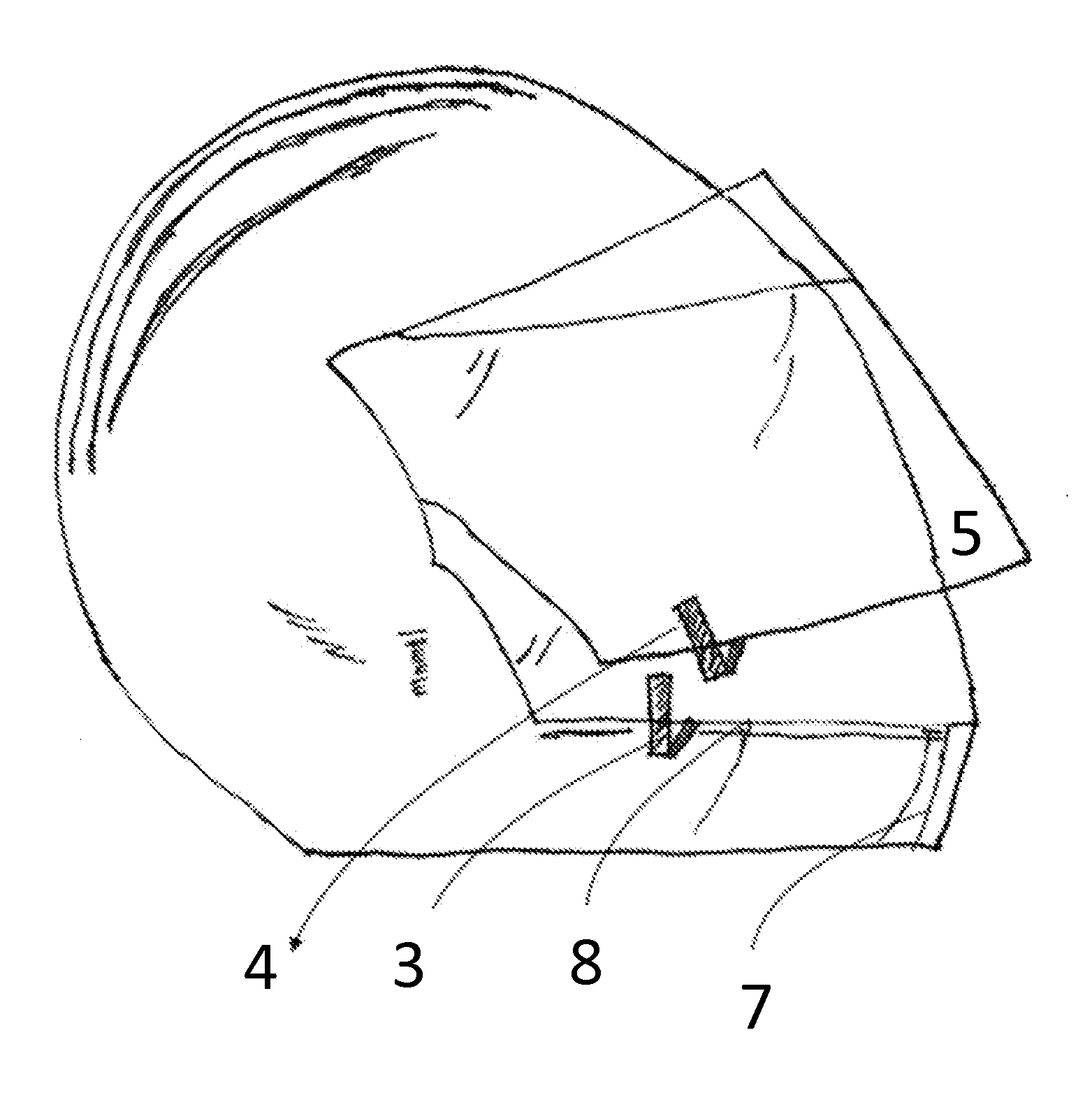

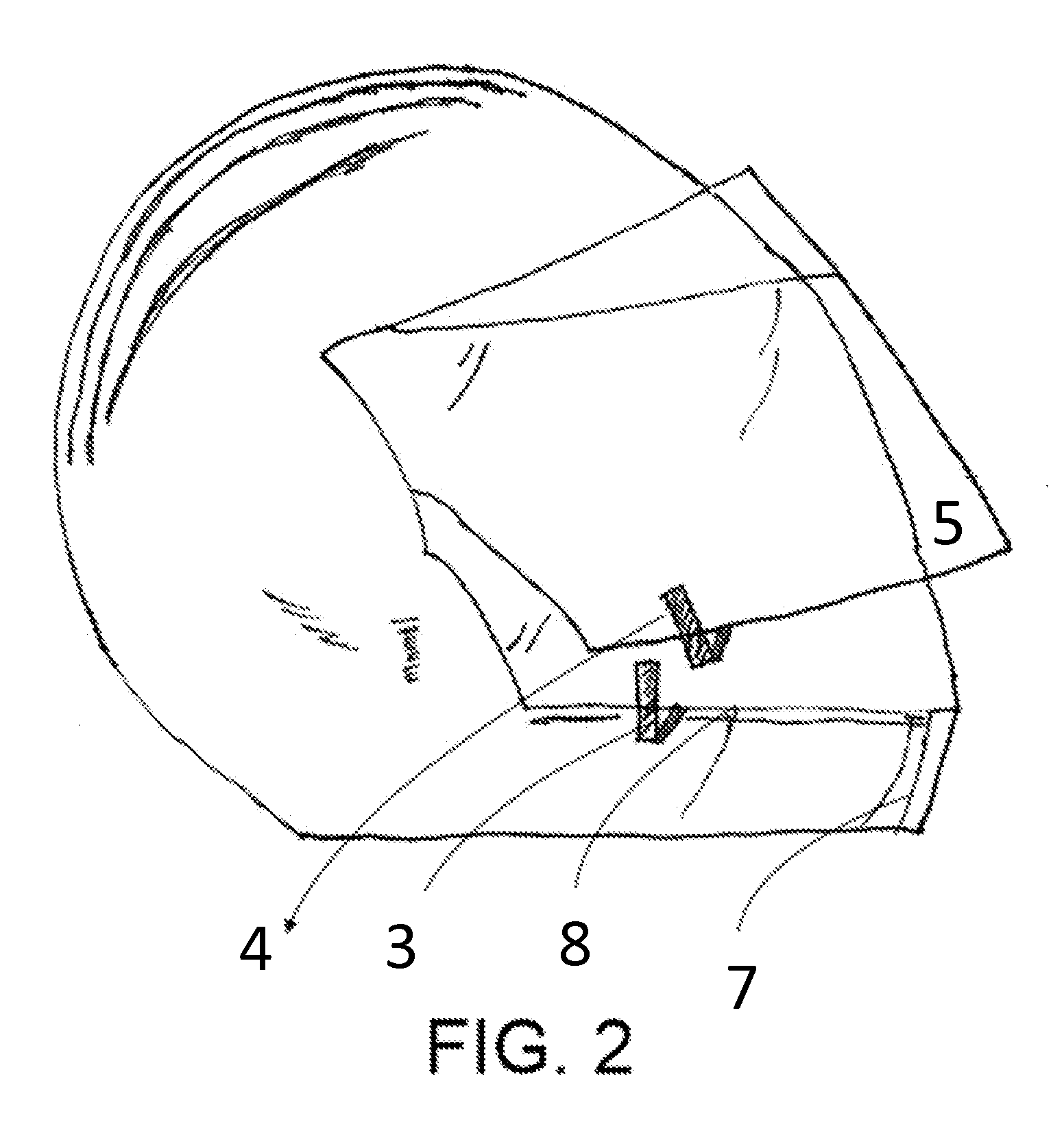

[0012]Referring to FIG. 2 it can be seen that this embodiment of the present invention is usable on the bottom of the full-face-type helmet windshield. FIG. 2 shows the windshield in both open and closed position. (3) shows the prop affixed to the windshield with the windshield closed. Note the visible gap in the drawing of the windshield were closed (8). (4) shows the invention af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com