Pre-Tensioned Discrete Element Support System

a discrete element and support system technology, applied in the direction of buildings, constructions, ways, etc., can solve the problems of increasing the moment load potential of the matting system, small mats are difficult to break, and the matting system fails to meet the needs of construction and construction, so as to facilitate the positive return and enhance the beam strength of the mat segments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

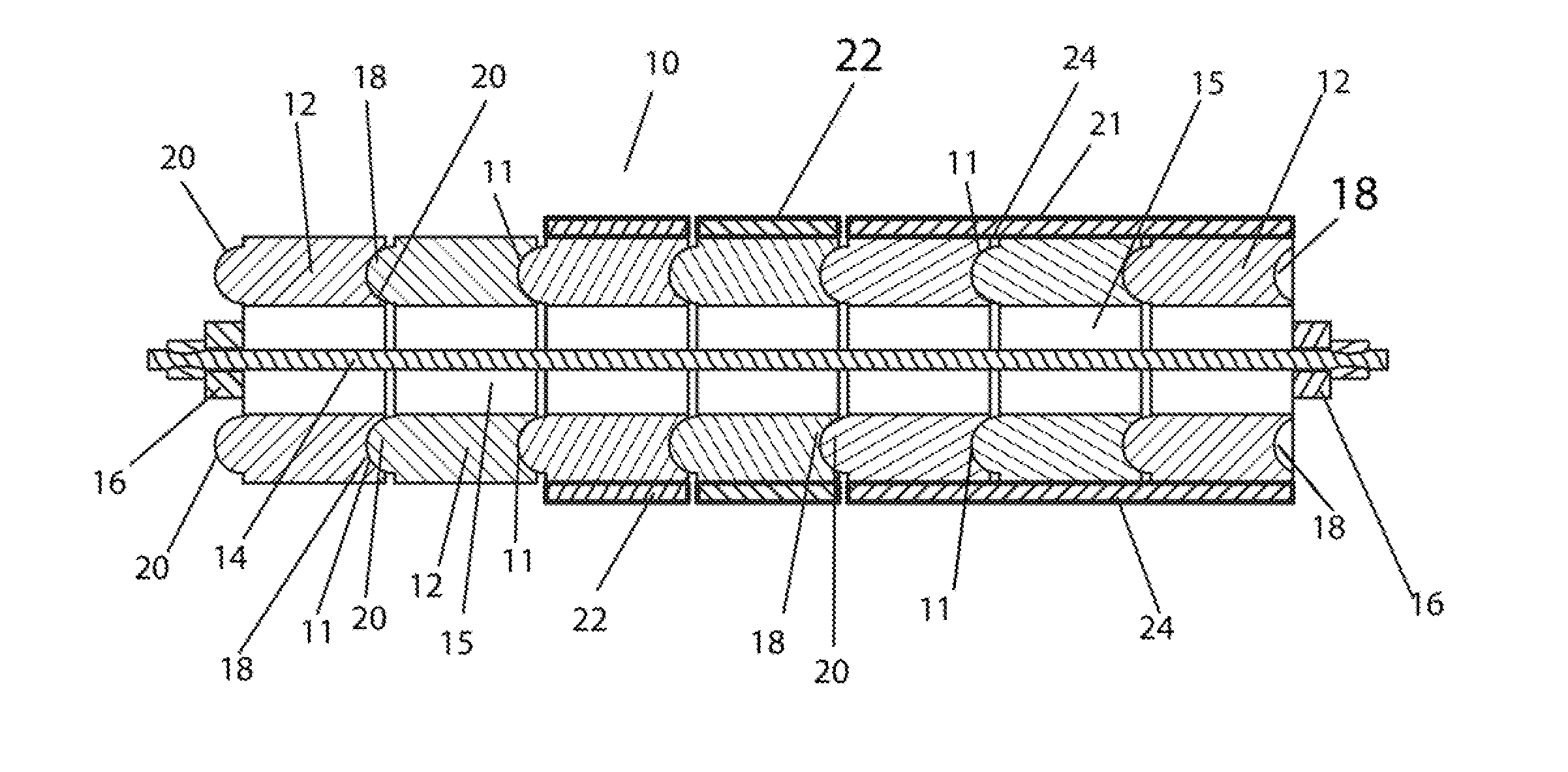

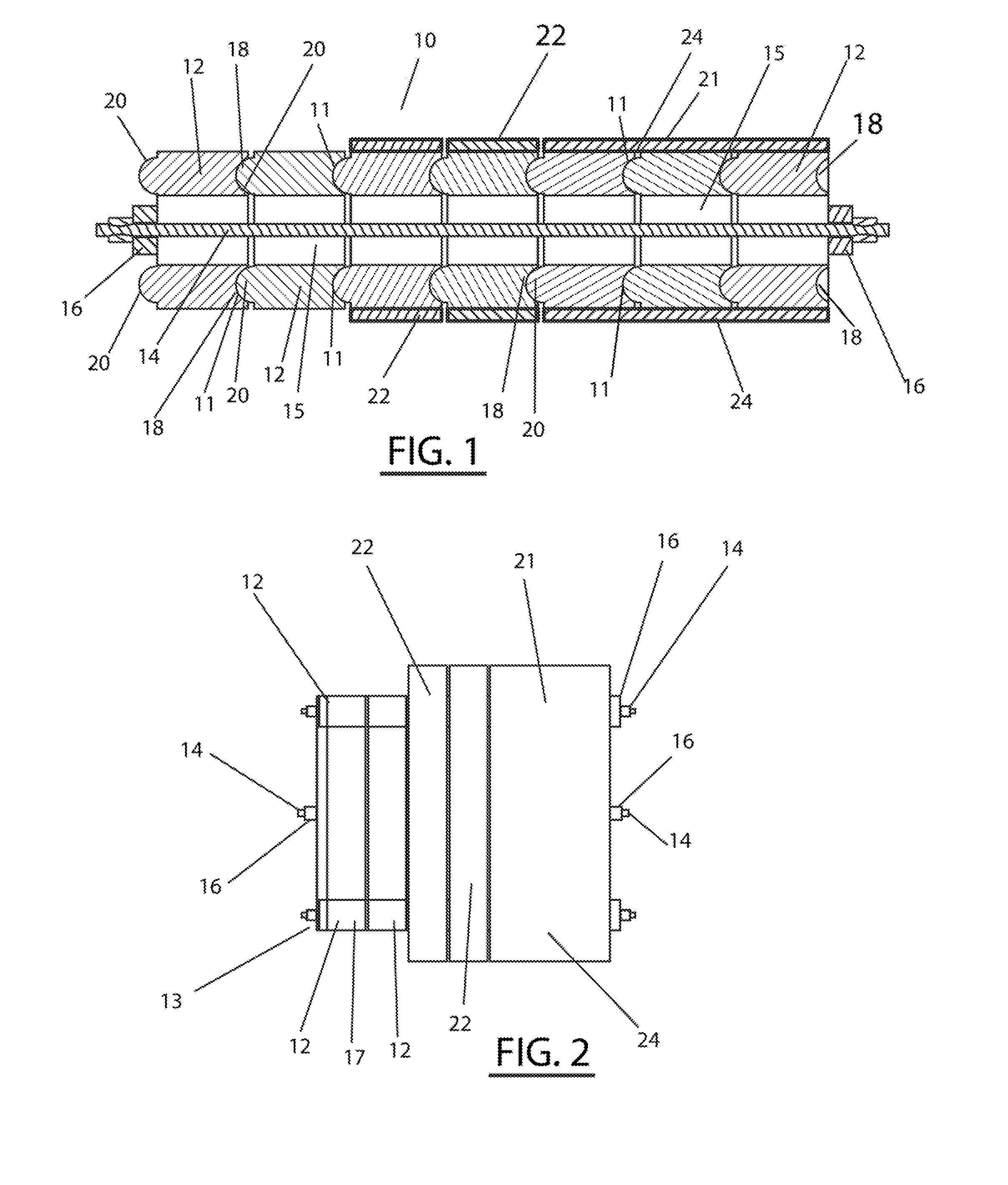

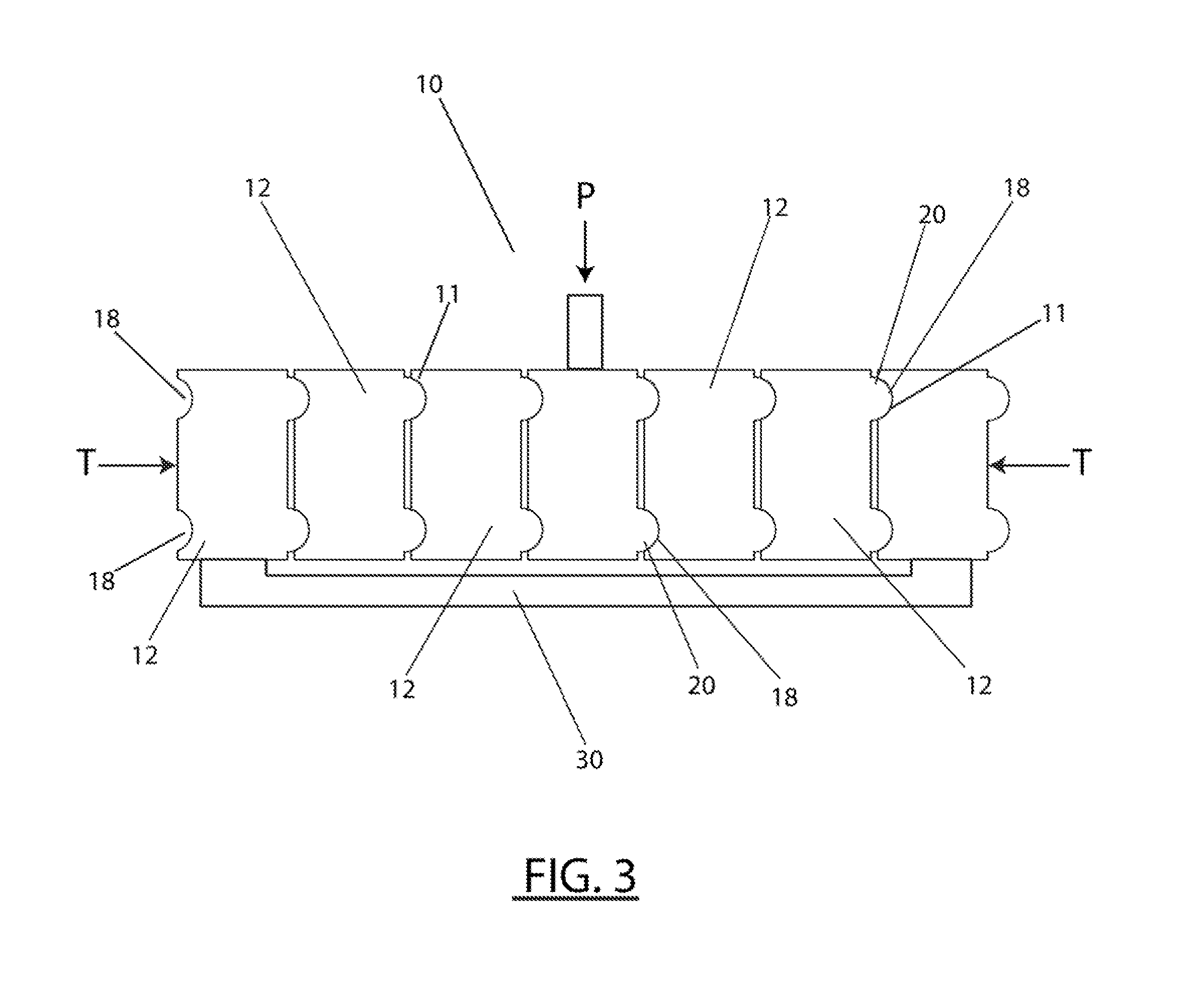

[0022]Referring now to FIG. 1 and FIG. 2, there is shown the matting system (10) of Applicant's invention. The matting system (10) is comprised of a plurality of discrete, individual mat segments (12), preferably in strips or splines, each having at least one retainer bore (15). The mat segments (12) are held together by a pre-tensioned wire or rod connector (14) positioned through the retainer bore (15) of the adjoining mat segments and secured in tension by a fastener such as a nut (16). Placing the connector (14) in tension in the manner similar to that used in post-tensioned concrete slabs is thought to be suitable. The wire or rod connector (14) may be of any suitable material thought it is thought that steel rods or steel wire cables will be utilized.

[0023]The mat segments (12) are designed to “give” or separate at their adjoining connecting surfaces (11) at a predetermined load as the pre-tensioned connector rod deforms when the matting system is overloaded. As shown multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com