Locking arrangement for sleeve-and-endcap package

a technology of end caps and locking arrangements, applied in the field of product packaging, can solve the problems of the amount of labor and materials required to construct the packag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

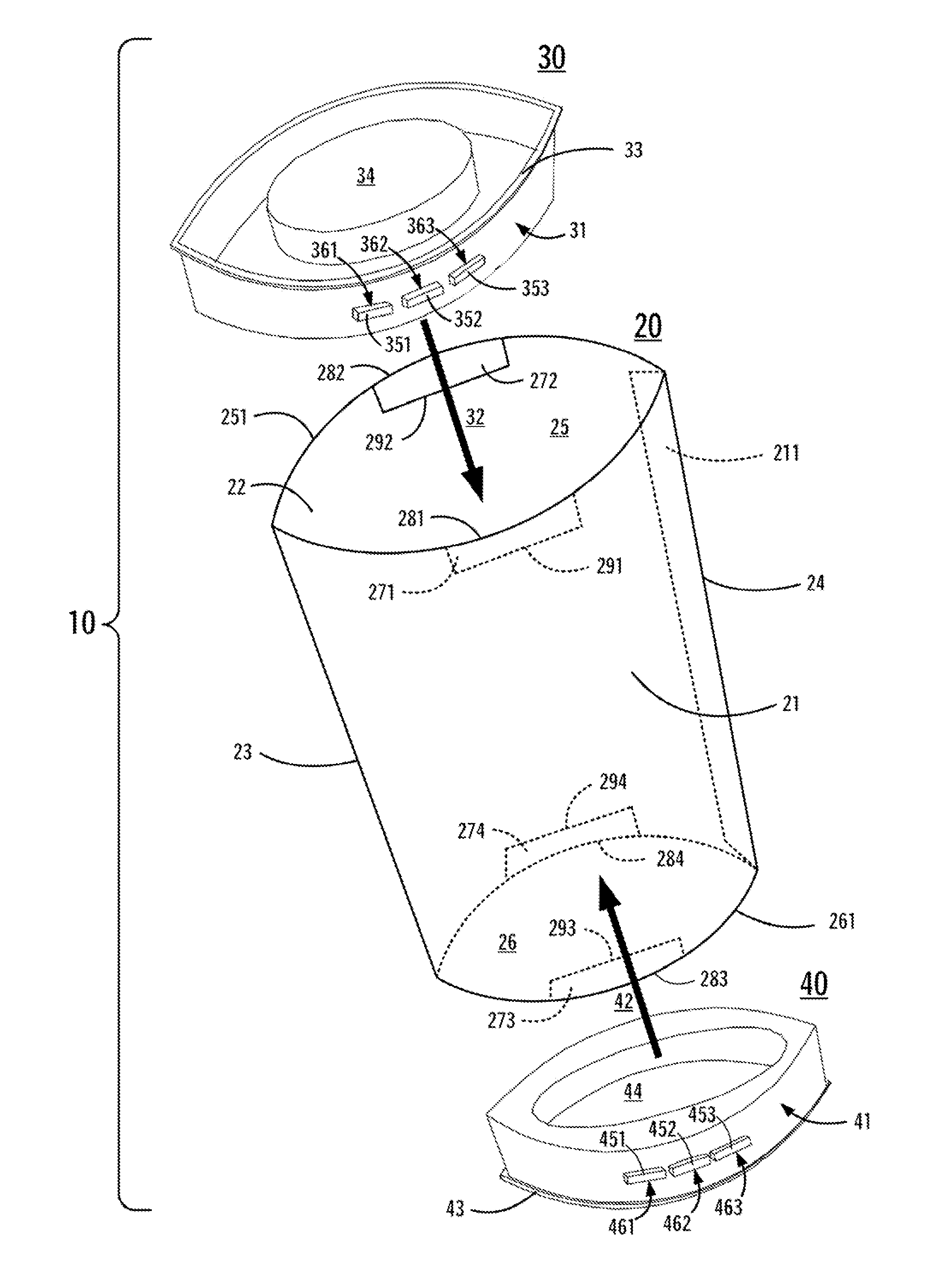

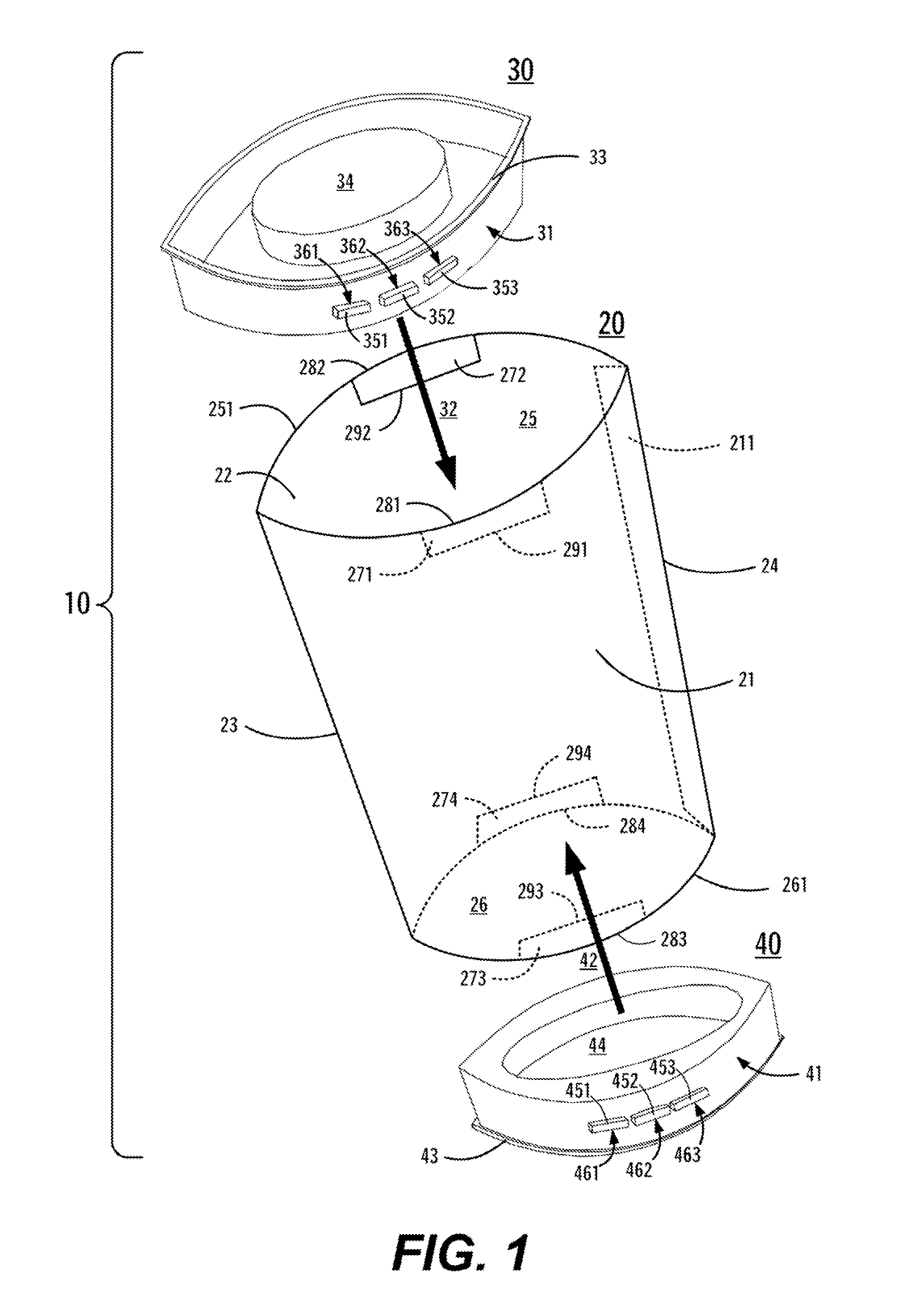

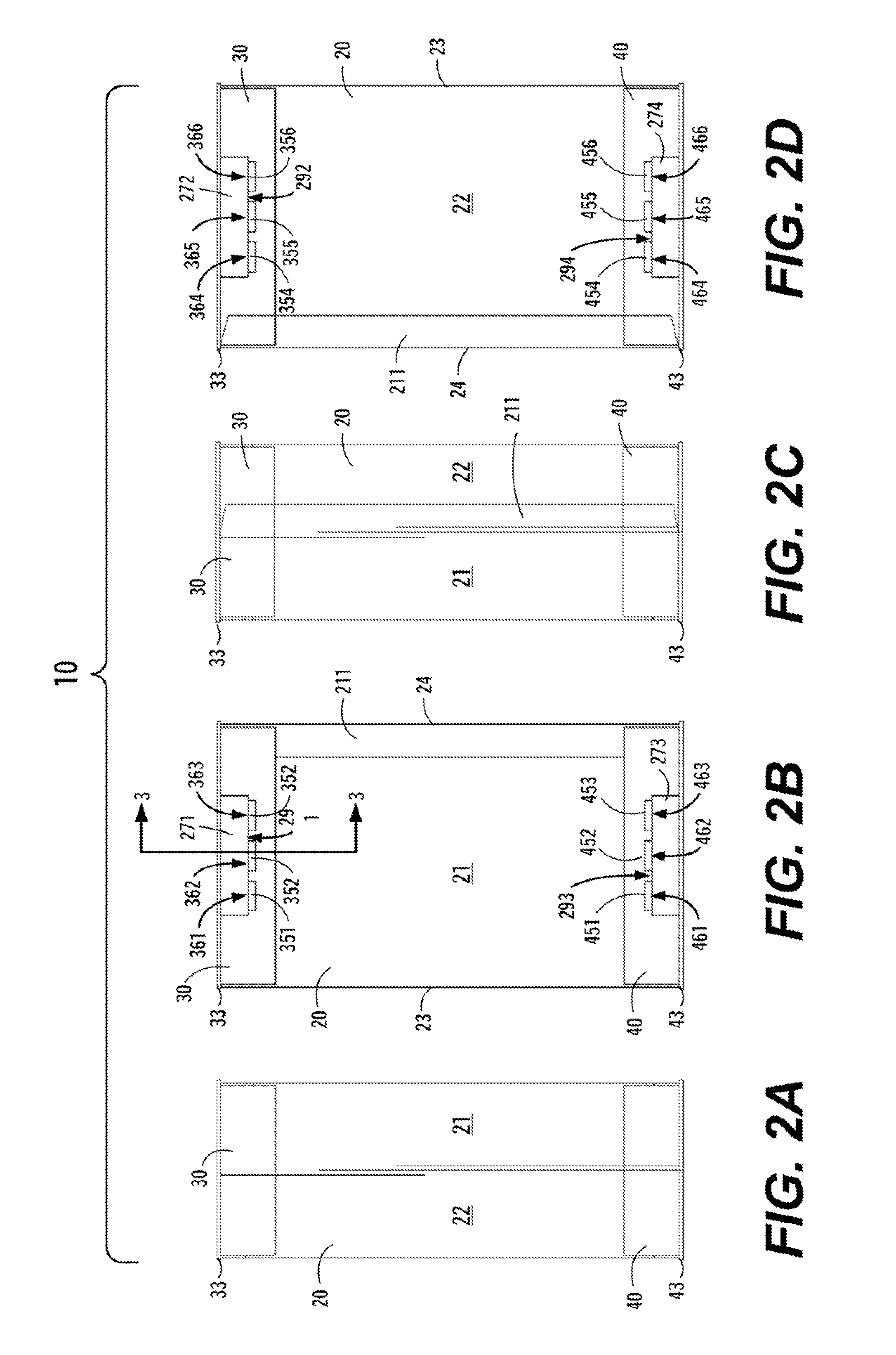

[0024]Aspects of the invention are directed to structures and techniques that, in a sleeve-and-endcap package, provide secure locking of one or more endcaps it its respective sleeve end. As discussed below, aspects of the invention can be used to create an endcap that is readily insertable into a sleeve and that, once fully seated, is securely locked in position. As further discussed below, the locking structures can be designed to be inconspicuous, such that they are virtually unnoticeable to a casual observer. Alternatively, the locking structures can be designed to contribute to the overall esthetic appearance of the package. For example, the locking bumps can incorporate the shape of a corporate logo or other design.

[0025]According to an aspect of the invention, the locking structure comprises one or more outwardly extending endcap bumps and one or more inwardly extending sleeve tabs corresponding in position to respective endcap bumps. The endcap bumps and the sleeve tabs are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com