Automatic locking slider for slide fastener

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

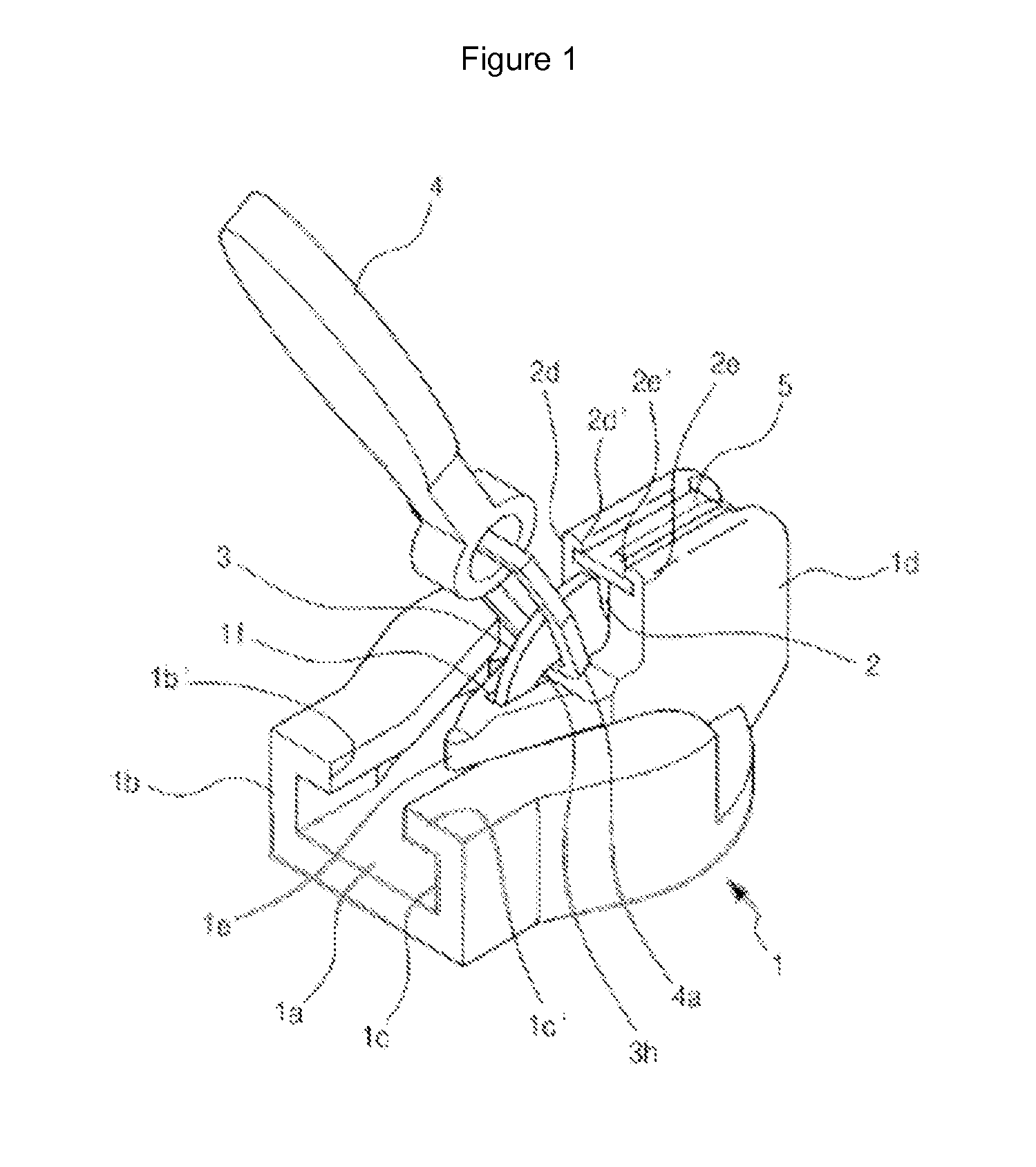

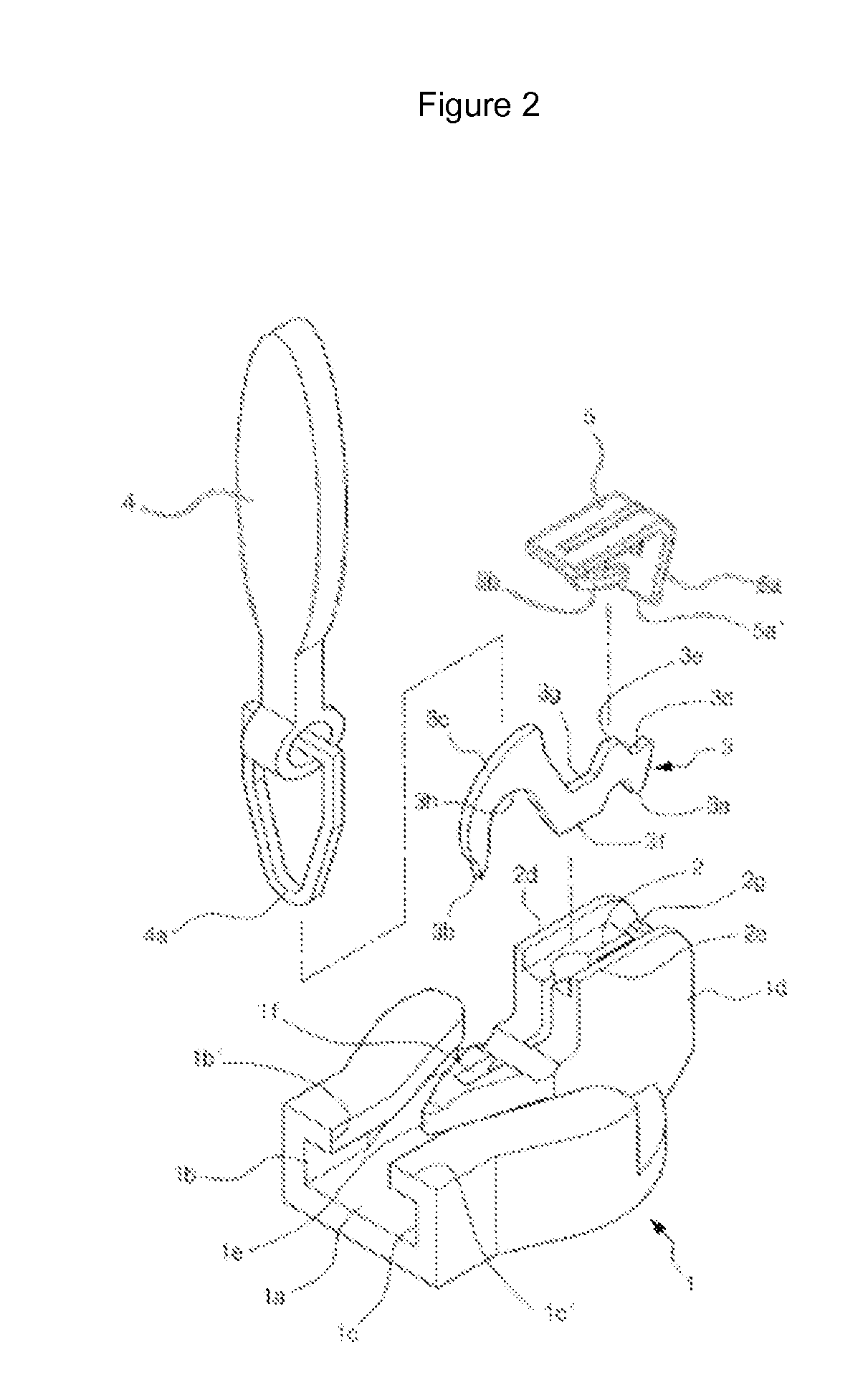

[0019]The preferred embodiments of the present invention will be described. There is provided an automatic locking slider for a slide fastener which has features in that side walls 1b and 1c are formed at the heights corresponding to the height of a fastener in an upward direction from an outer surface of the bottom plate so that a Y-shaped fastener engaging groove is formed on an upper surface of a bottom plate 1a of a slider body, and inward wings 1b′ and 1c′ are formed facing each other in inward directions at the tops of the side walls, and a fastener engaging groove is formed so that the fasteners of both sides can be guided by the side walls and the inward wings, and

[0020]a locking lever accommodation groove 2 is formed in such a way that a guide pillar 1d extends in an upward direction from the center of the side of an input part of the fastener engaging groove, and its top and inner side portion are open at a central portion of the guide pillar, and a central wing 2e whose t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com