Package Assembly with Tear Away Film and Manufacturing System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]In order to reduce, or overcome, the problems associated with traditional packaging methods, apparatus, and assemblies, a new package assembly, method of producing the package assembly, and packaging apparatus are herein disclosed. Each is described, in turn, in the following description.

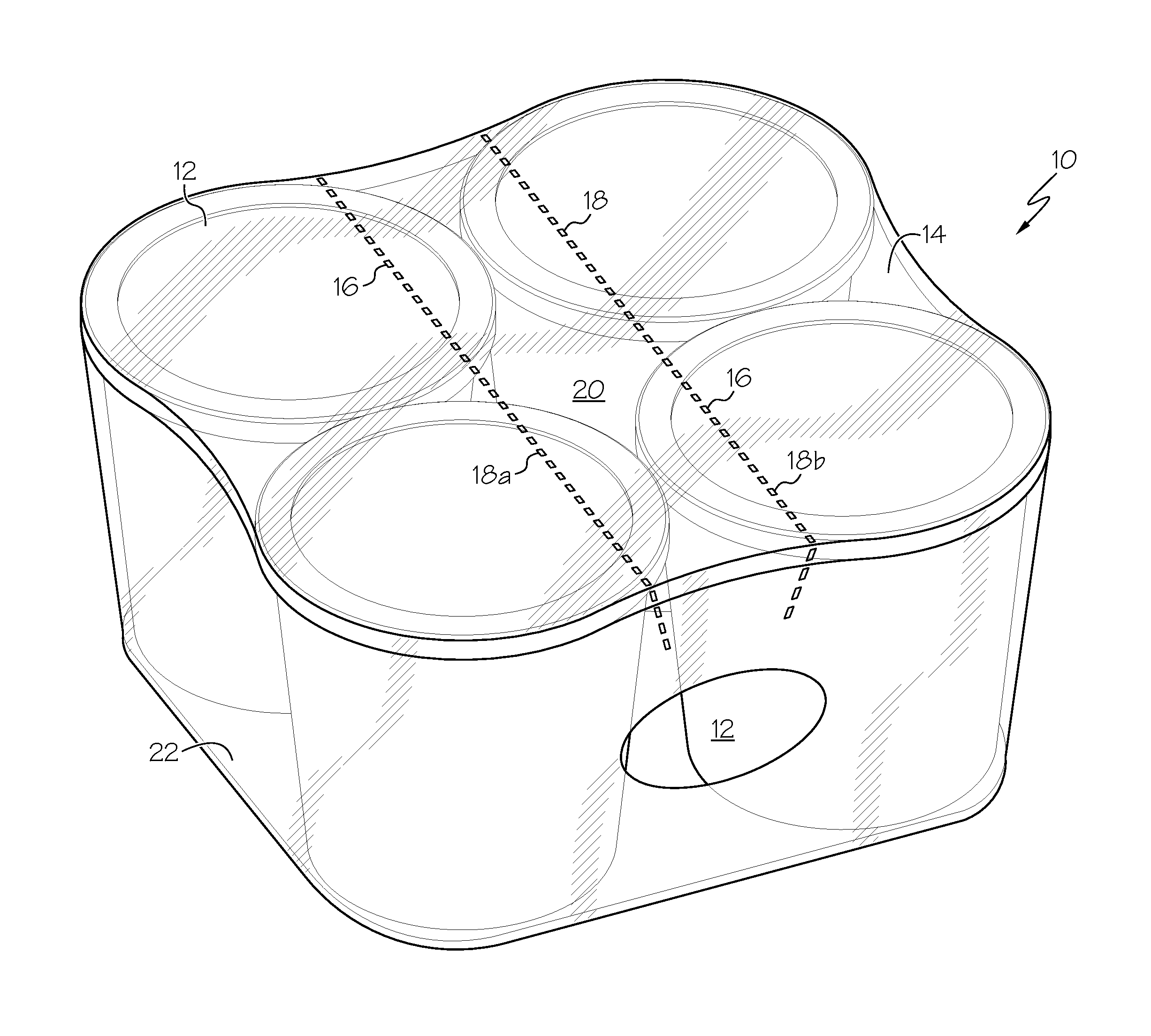

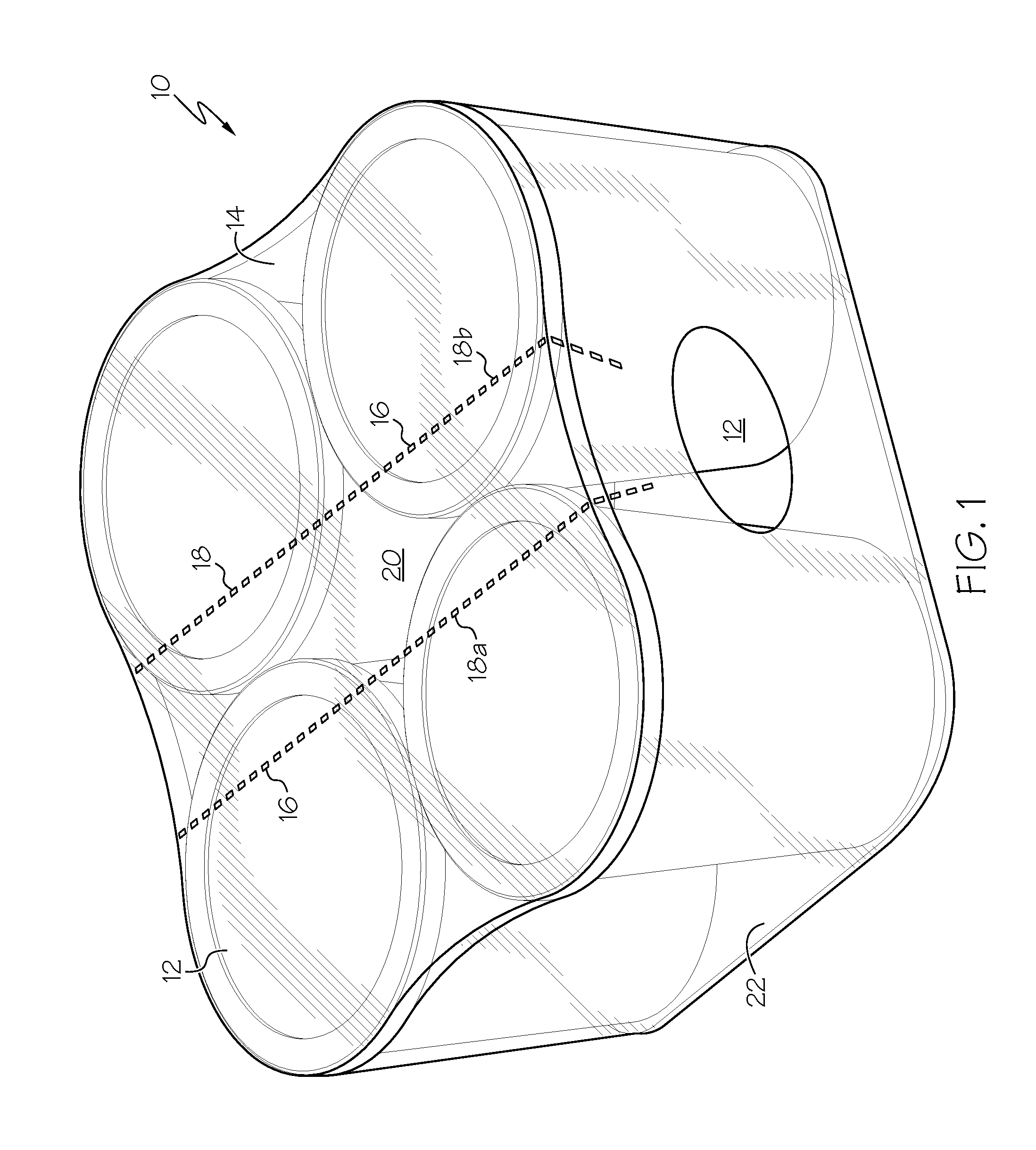

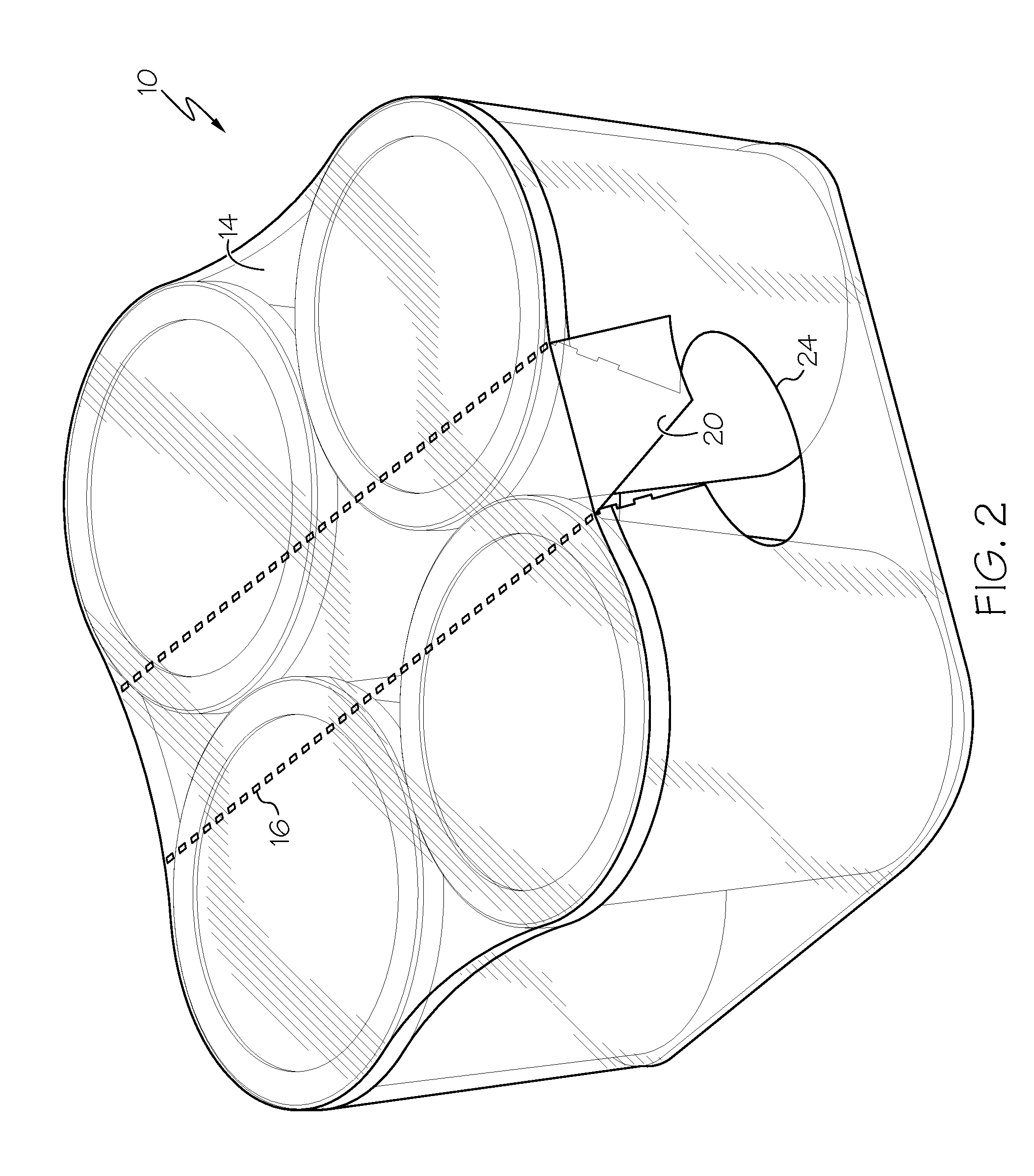

Package Assembly

[0033]With regard to FIG. 1, a package assembly 10 is shown. The package assembly includes a plurality of containers 12 and a film or heat-shrink wrapping 14. The containers 12 can be of any desirable shape or configuration, for example cylindrical, conical, frusto-conical, spherical, cuboid, pyramidal, and combinations thereof. Additional examples of suitable packaging configurations can be found in U.S. Pat. Nos. 7,604,114 to Gessler, 7,392,905 to Andersen, 7,370,761 to Andersen, 6,588,594 to Andersen, 5,887,717 to Anderson, and 7,467,504 to Mate, the contents of each of which are herein incorporated by reference in their entirety.

[0034]In addition to the foregoing, the heat-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap