Hook-and-loop component embedded with foam material and cushion thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]A hook-and-loop component embedded with a foam material and a cushion thereof are disclosed in the present invention. The detailed description of the present invention will be discussed in the following embodiments, which are not intended to limit the scope of the present invention, but can be adapted for other applications. While drawings are illustrated in details, it is appreciated that the quantity of the disclosed components may be greater or less than that disclosed, except expressly restricting the amount of the components.

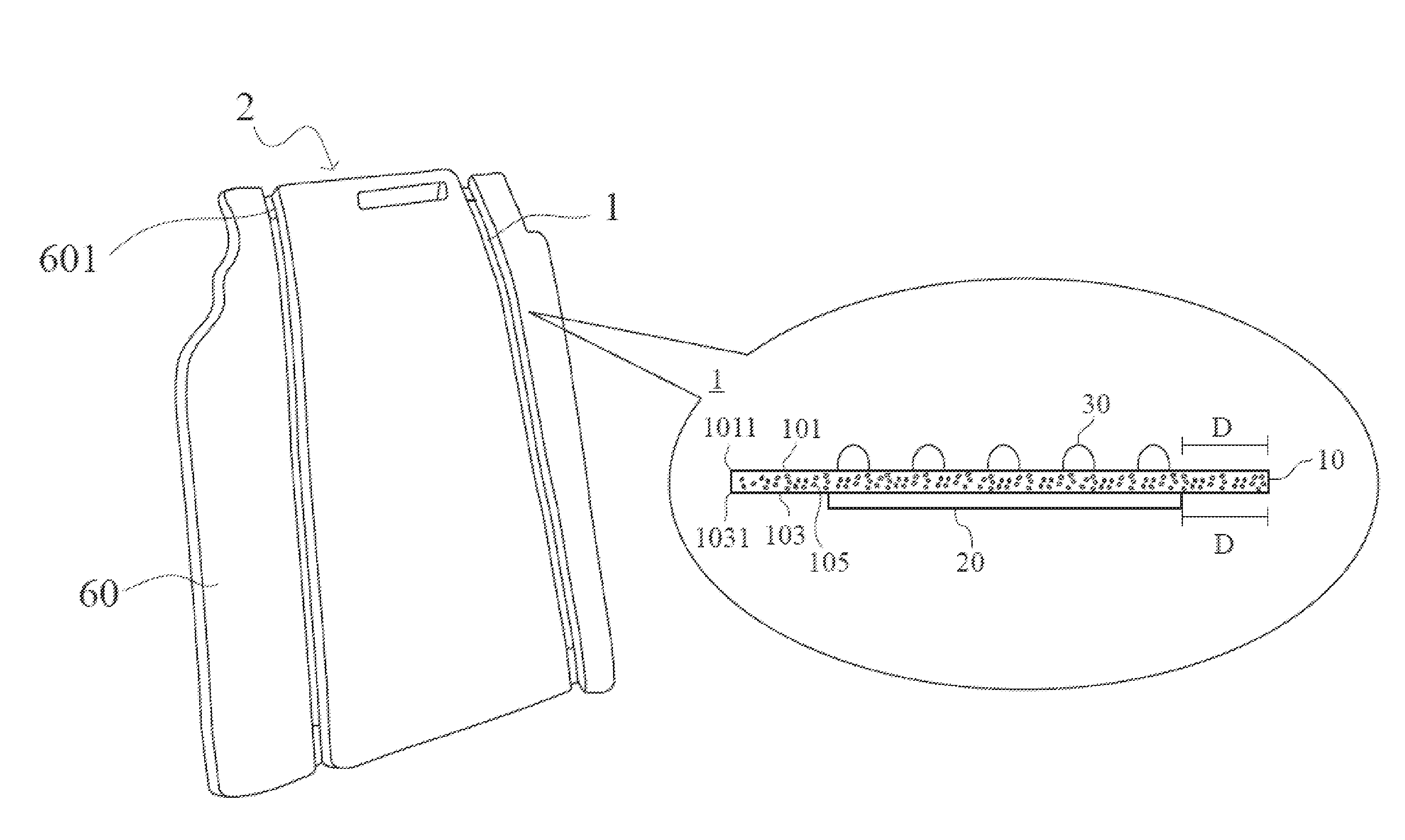

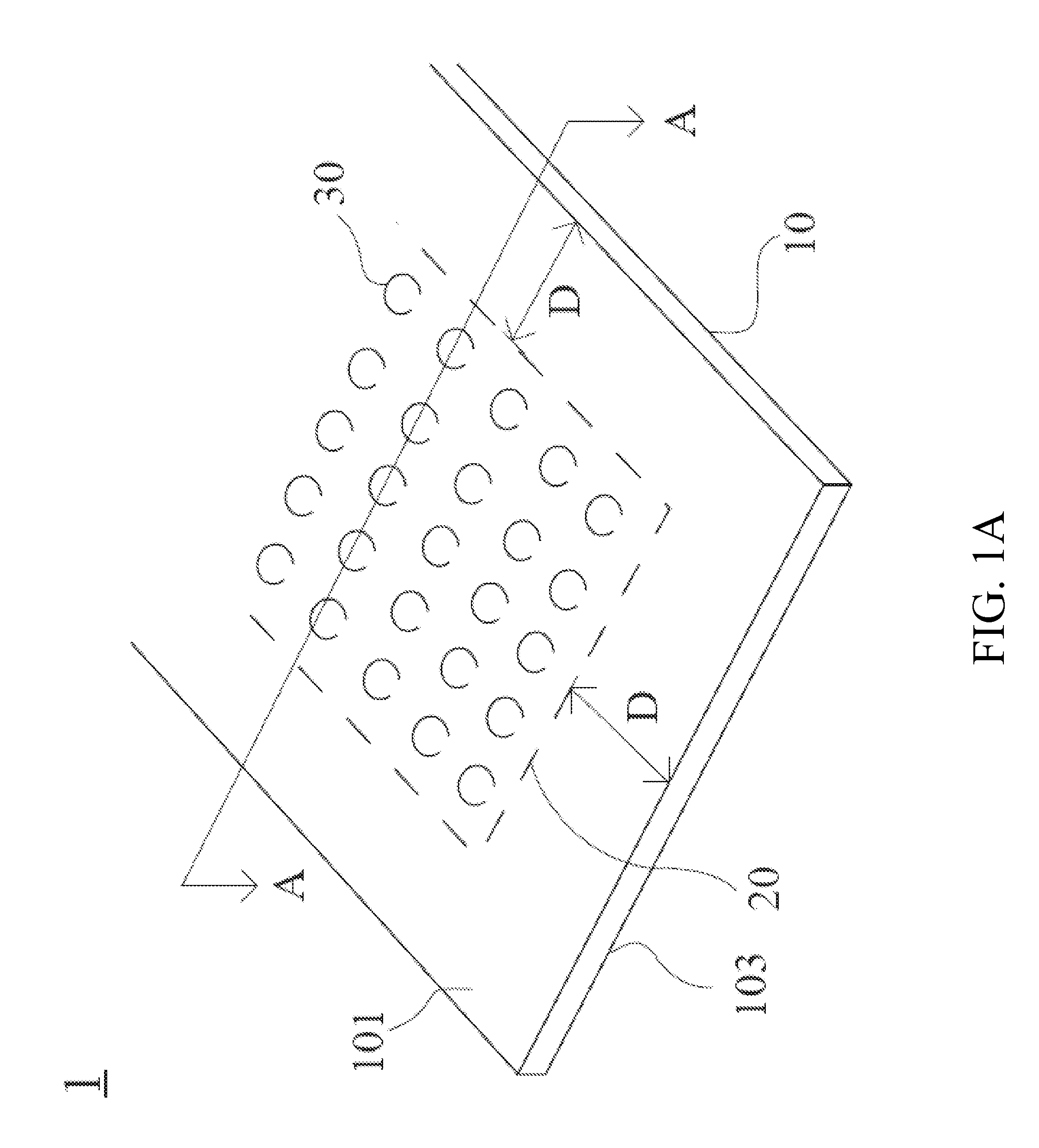

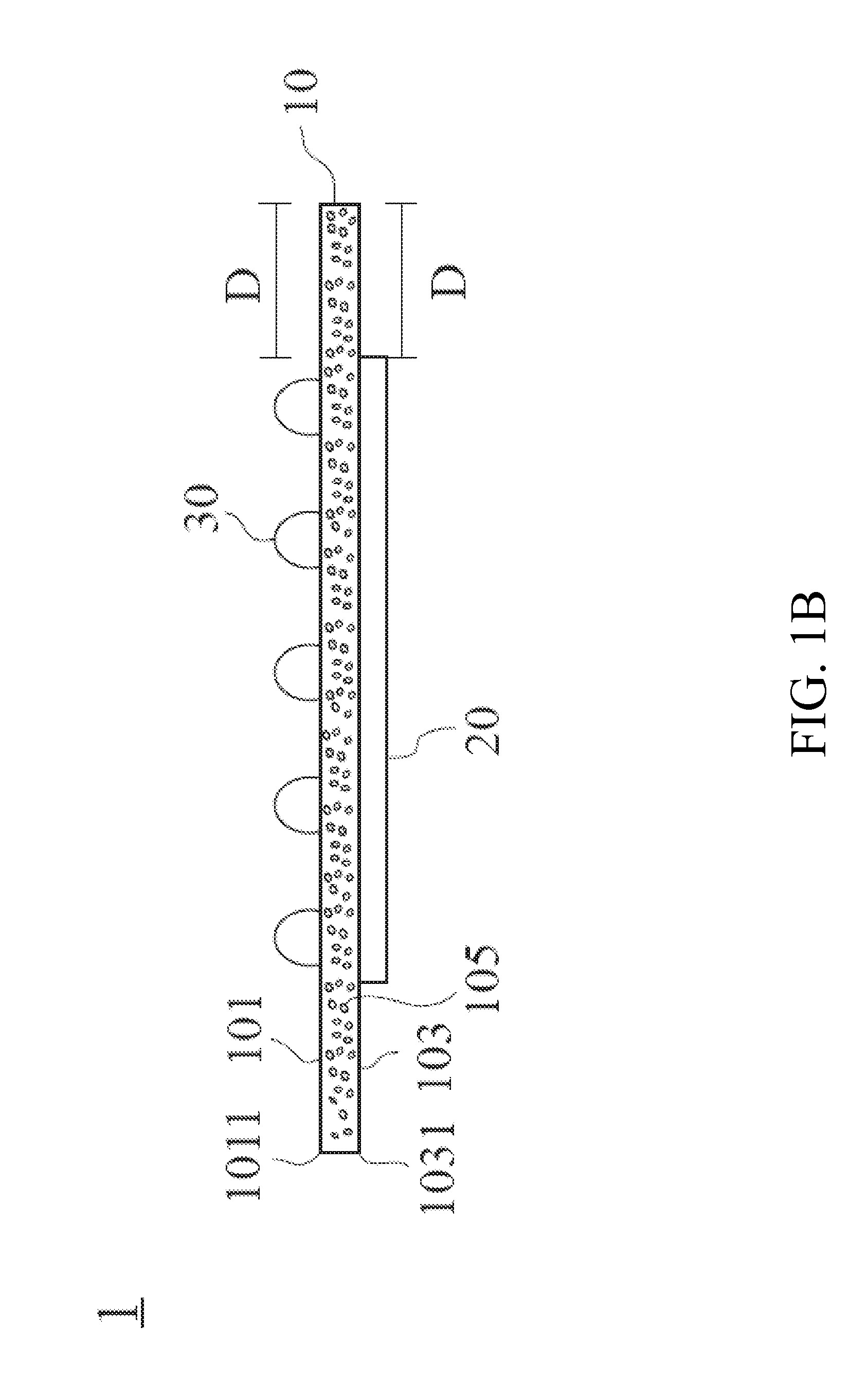

[0020]Please refer to FIG. 1A and FIG. 1B, which are respectively illustrating a view and an A-A line sectional view of FIG. 1A of a hook-and-loop component in one embodiment of the present invention. The hook-and-loop component 1 includes a band body 10, a plurality of hair hoops 30 and a magnetic material 20. The band body includes a first surface 101 and a second surface 103 and the first surface 101 and the second surface 103 are opposite to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com