Tent Hub Assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Certain terminology is used in the following description for convenience only and is not limiting. The article “a” is intended to include one or more items, and where only one item is intended the term “one” or similar language is used. Additionally, to assist in the description of the present invention, words such as top, bottom, upper, lower, front, rear, inner, outer, right and left are used to describe the accompanying figures. The terminology includes the words above specifically mentioned, derivatives thereof, and words of similar import.

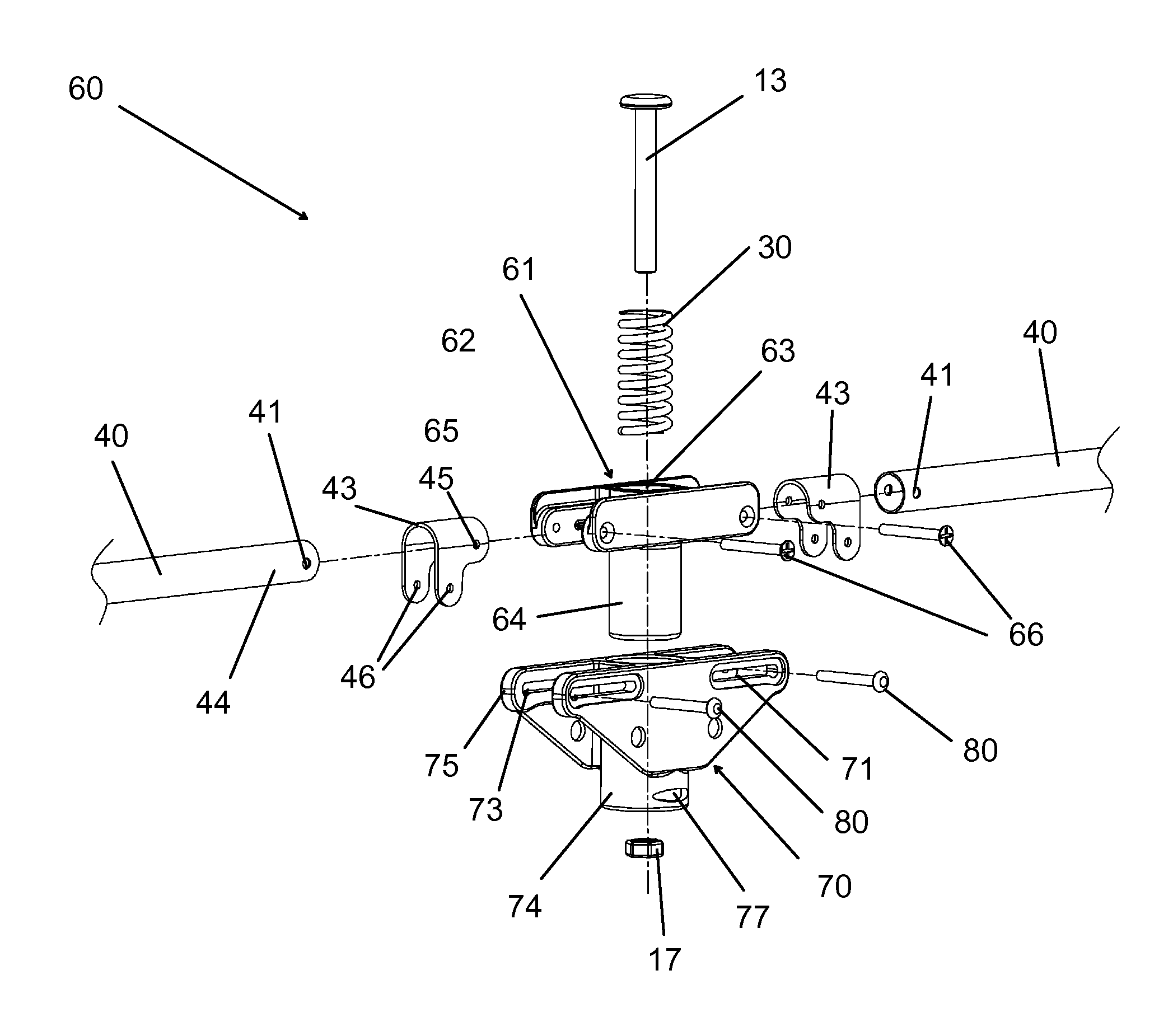

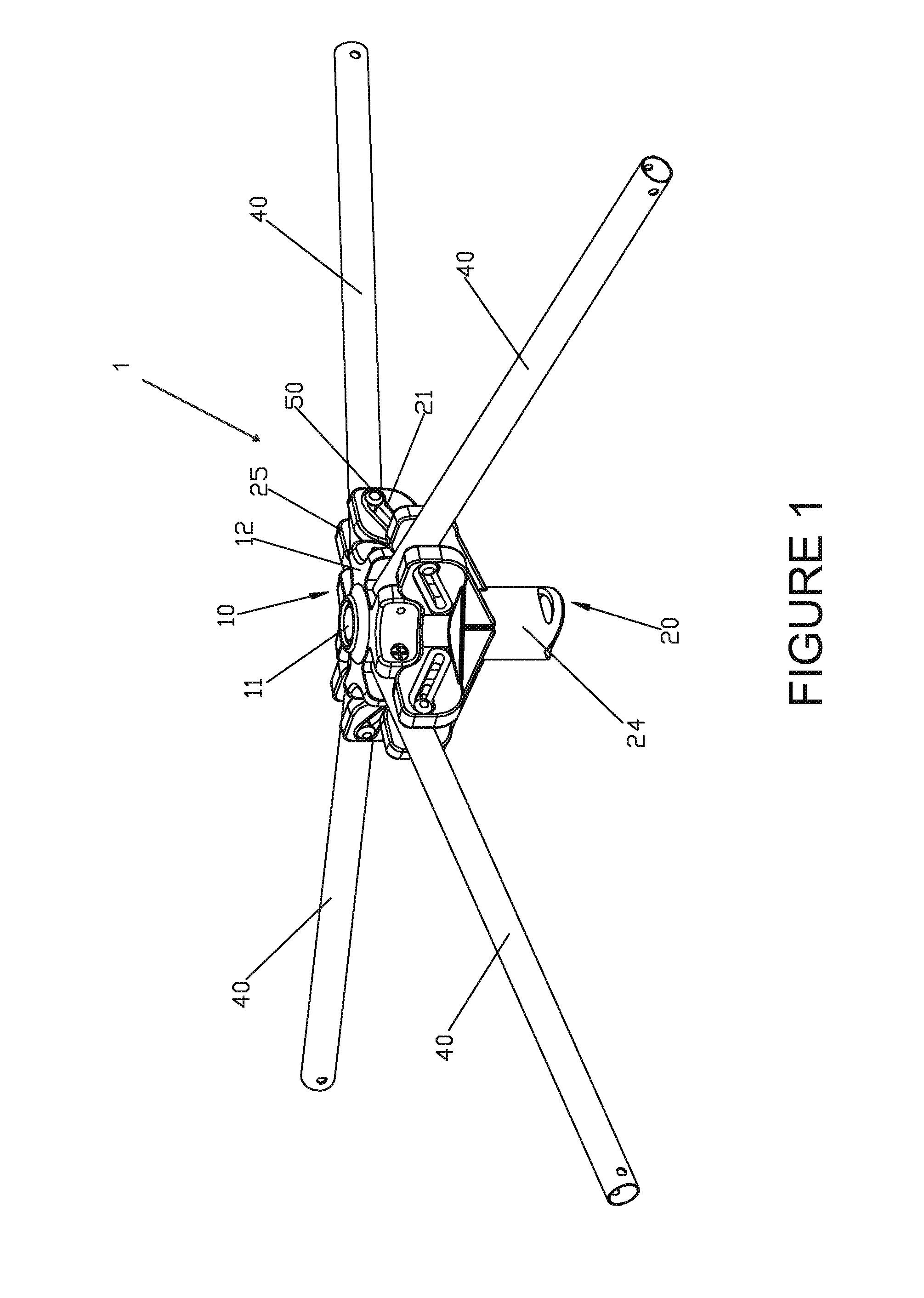

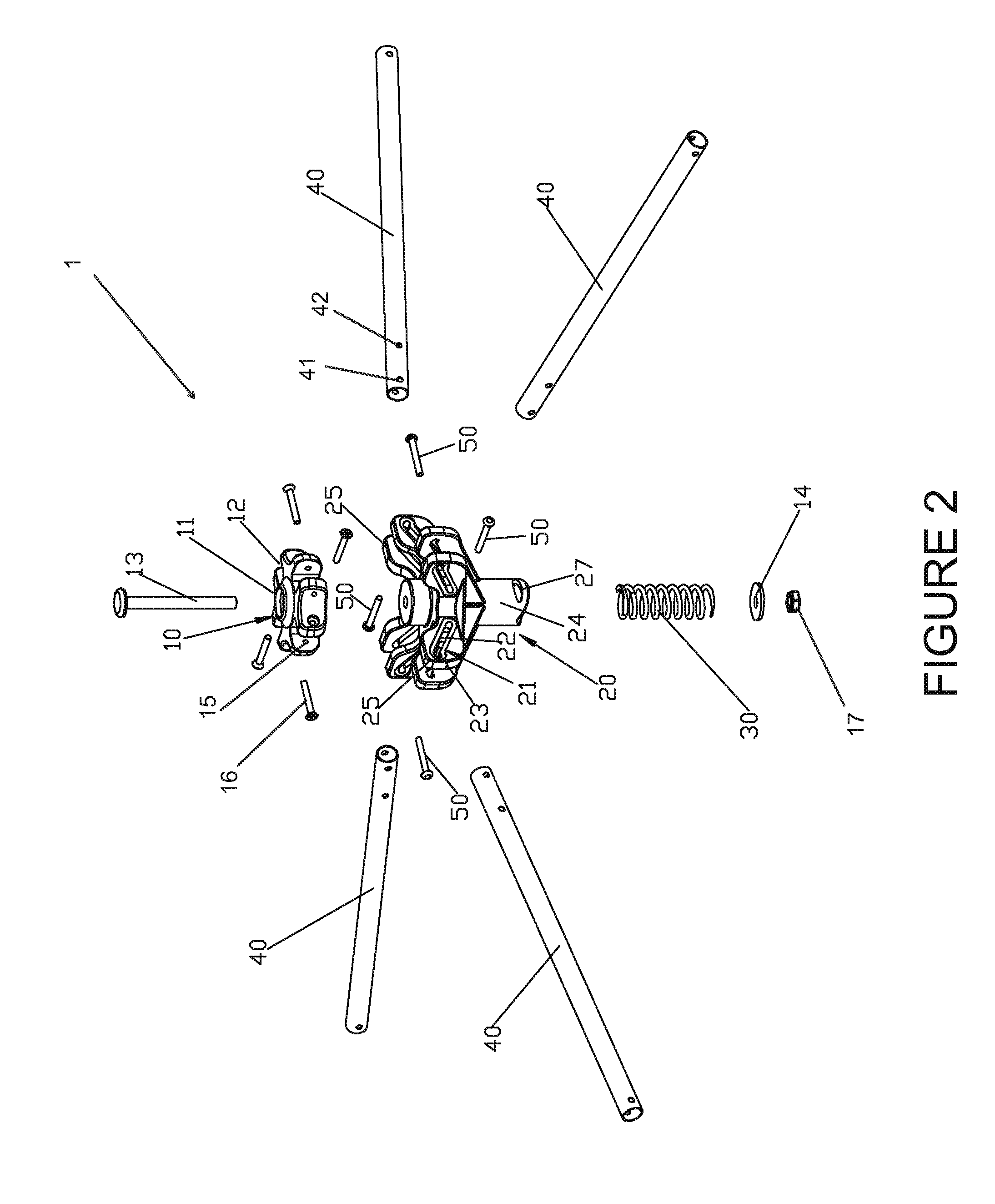

[0037]Referring to FIGS. 1-8, the hub assembly 1 is connected to the ends of a plurality of poles 40 of a tent, as shown in FIG. 8, which have the tent fabric attached to the poles 40. As shown in FIGS. 1-2, the hub assembly 1 has a body or hub 10 with a plurality of hub arms 12 radially extending from a central portion having a central aperture 11. Each hub arm 12 has a fastener aperture 15 which receives a fastener 16 that passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com