Material-feeding automatic detecting device and the chemical producing system

An automatic detection device, chemical production technology, applied in the direction of feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as reaction equipment failures, and achieve the effect of maintaining insulation and tight cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

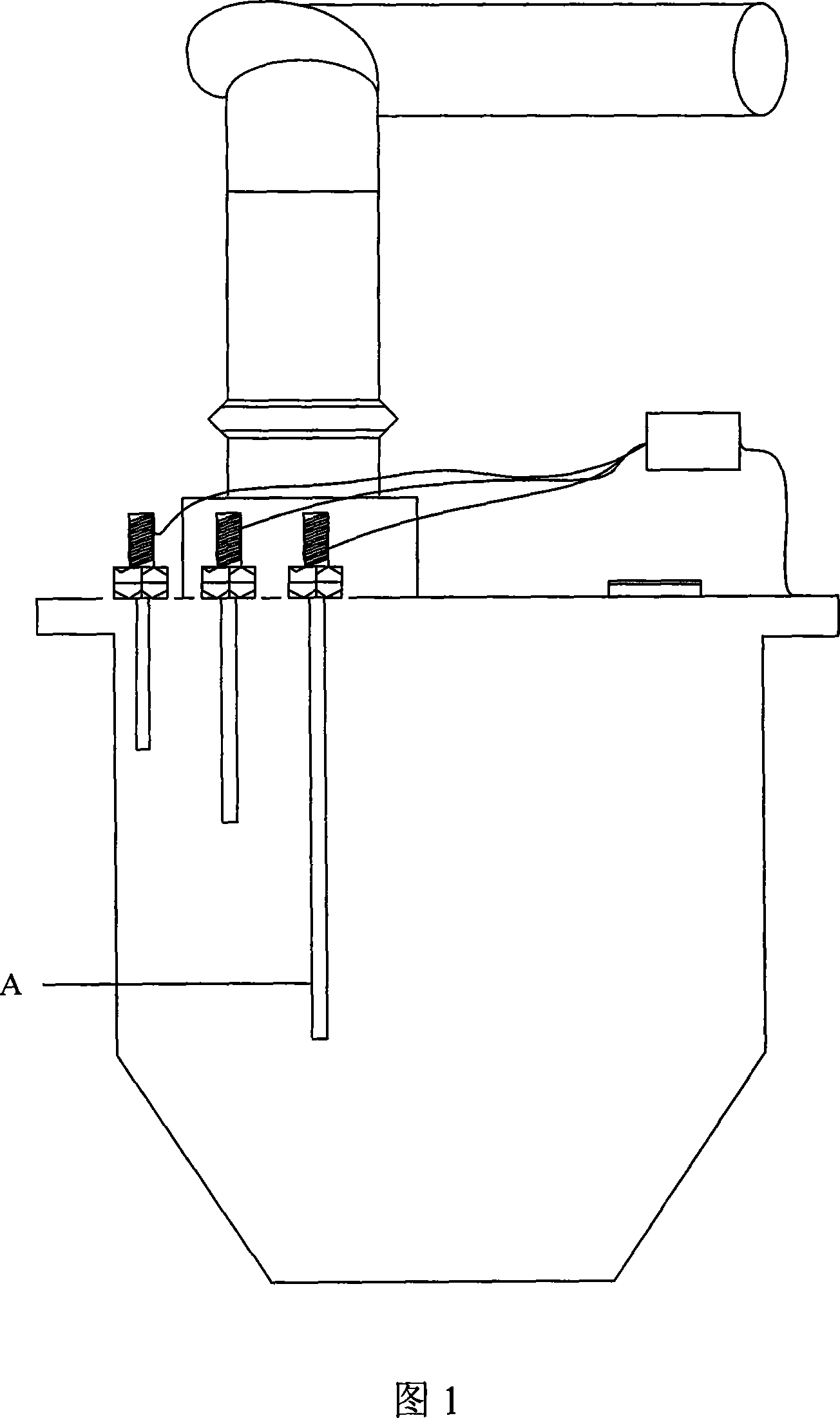

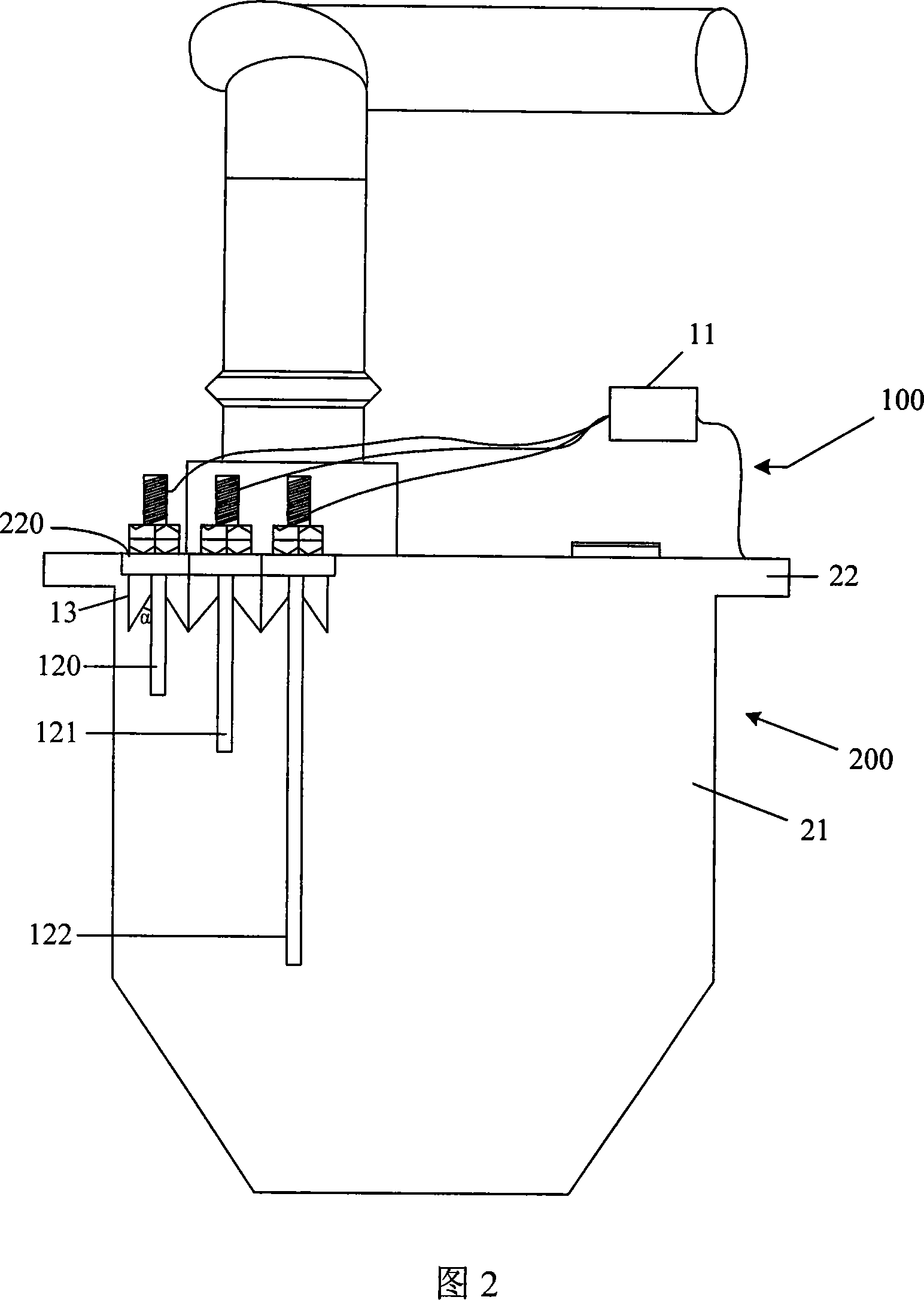

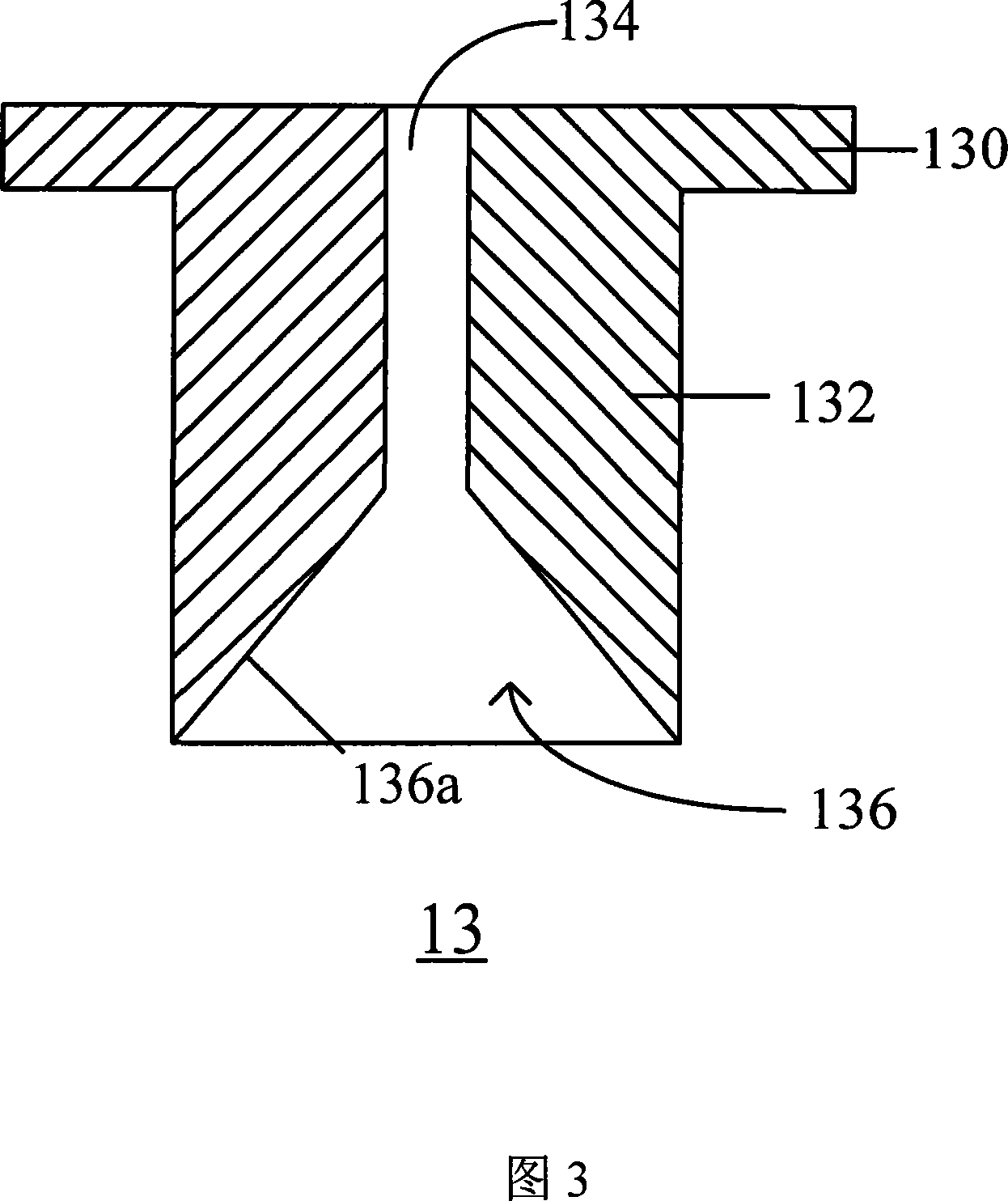

[0017] Fig. 2 is a schematic diagram of the installation of the automatic feeding detection device of the present invention. As shown in FIG. 2 , the automatic feeding detection device 100 is used to detect the stocking condition of the reactor 200 , and includes a controller 11 , three detection rods 120 , 121 and 122 of different lengths and an insulating block 13 .

[0018] Wherein, the reaction kettle 200 includes a conical kettle body 21 and a kettle cover 22 , the opening and closing of the kettle body 21 is realized through the kettle cover 22 , and three openings 220 are opened on the kettle cover 22 . The fixed ends of the detection rods 120, 121 and 122 are respectively installed on the kettle cover 22 by fasteners, while the detection ends extend vertically into the inside of the kettle body 21 from the opening 220, wherein the detection rod 120 has the shortest length , that is, the distance between the detection end and the kettle cover 22 is the shortest, and it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com