A kind of highly acidic low crystallinity aluminum oxide dry glue and preparation method thereof

A technology of alumina dry glue and low crystallinity, which is applied to chemical instruments and methods, alumina/aluminum hydroxide, catalyst carriers, etc., to achieve the effects of improving acidity, good adhesiveness, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

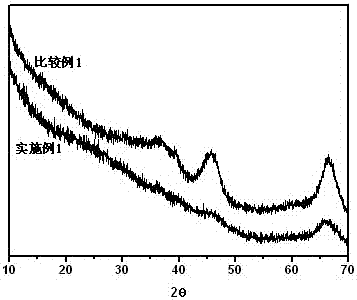

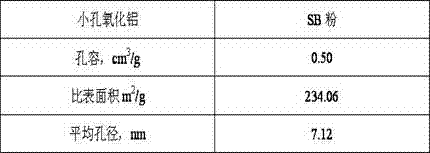

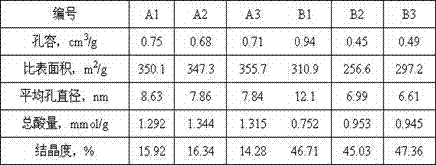

Image

Examples

Embodiment 1

[0023] Put 1 L of aluminum sulfate solution (concentration of 0.2 mol / L) in a raw material tank, and the raw material tank is placed at room temperature at 20°C; 1 L of sodium metaaluminate solution (concentration of 0.3 mol / L) in another raw material tank In the tank, the raw material tank is heated by hot water circulation to control the temperature at 80°C. Add 300 g of sodium dodecylbenzenesulfonate into the sodium metaaluminate solution while stirring, and wait for it to dissolve completely for later use.

[0024] 500mL of pure water was placed in the reaction tank as the bottom liquid, the temperature of the reaction tank was controlled to 50°C through hot water circulation, and a small amount of sodium hydroxide was added to make the pH of the solution 7.5. The sodium metaaluminate solution was injected into the reaction tank at a rate of 10 mL / min, while the aluminum sulfate solution was injected and the rate was adjusted to keep the pH value of the reaction tank solut...

Embodiment 2

[0029] Put 1 L of aluminum sulfate solution (concentration: 0.2 mol / L) in a raw material tank, and the raw material tank is kept at room temperature, with a temperature of 20°C. 1 L of sodium metaaluminate solution (concentration: 0.3 mol / L) was placed in another raw material tank, and the temperature of the raw material tank was controlled at 85 °C by hot water circulation heating. The anionic surfactant is replaced by sodium lauryl sulfate, and the addition amount is 400g, and it is set aside after being uniformly dissolved.

[0030] 600mL of pure water was placed in the reaction tank as the bottom liquid, the temperature of the reaction tank was controlled to 40°C through hot water circulation, and a small amount of sodium hydroxide was added to make the pH of the solution 8.0. The sodium metaaluminate solution was injected into the reaction tank at a rate of 15mL / min, while the aluminum sulfate solution was injected and the rate was adjusted so that the pH value of the rea...

Embodiment 3

[0033] Put 1 L of aluminum sulfate solution (concentration: 0.2 mol / L) in a raw material tank, and the raw material tank is kept at room temperature, with a temperature of 20°C. 1 L of sodium metaaluminate solution (concentration: 0.3 mol / L) was placed in another raw material tank, and the temperature of the raw material tank was controlled at 85 °C by hot water circulation heating. Replace the anionic surfactant with 90 g of potassium octadecanoate and 150 g of sodium lauryl sulfate, and wait until they are uniformly dissolved for later use.

[0034] 600mL of pure water was placed in the reaction tank as the bottom liquid, the temperature of the reaction tank was controlled to 40°C through hot water circulation, and a small amount of sodium hydroxide was added to make the pH of the solution 8.0. The sodium metaaluminate solution was injected into the reaction tank at a rate of 15 mL / min, while the aluminum sulfate solution was injected and the rate was adjusted to keep the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com