A safe anti-overflow electric kettle

An electric kettle and anti-overflow technology, applied in the direction of preventing overflow, boiling water, etc., can solve the problems of insufficient safety, high cost of heavy hammer, poor function, etc., to improve safety, facilitate temperature sensing, and use light Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

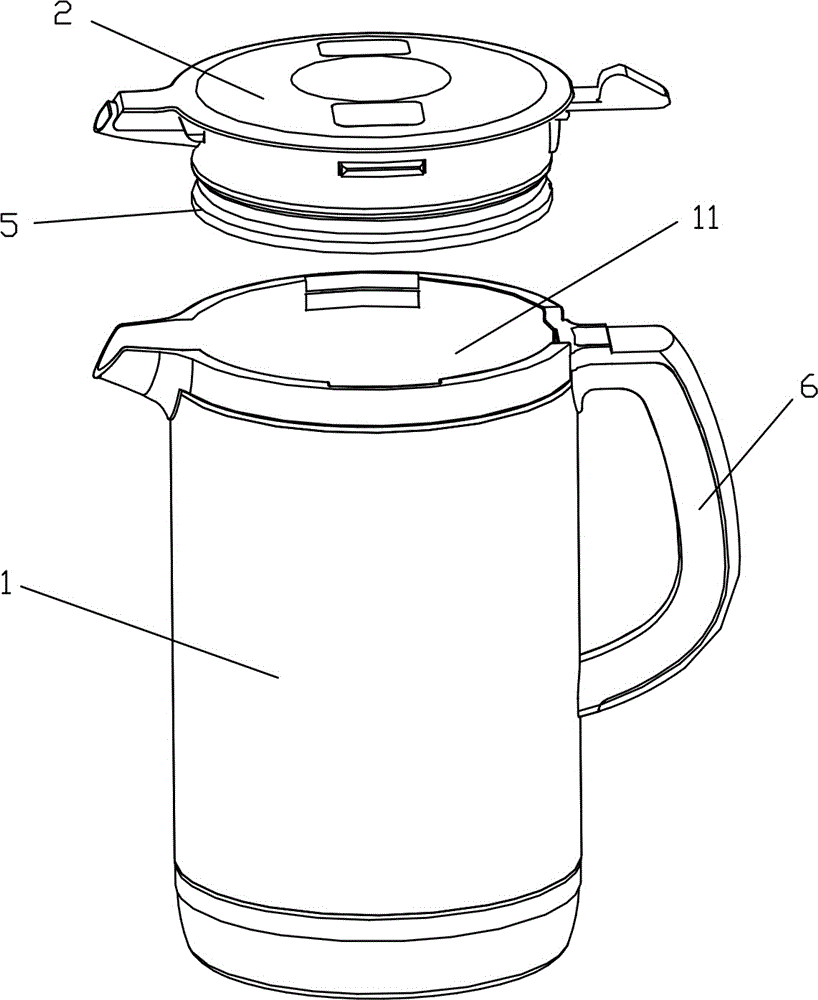

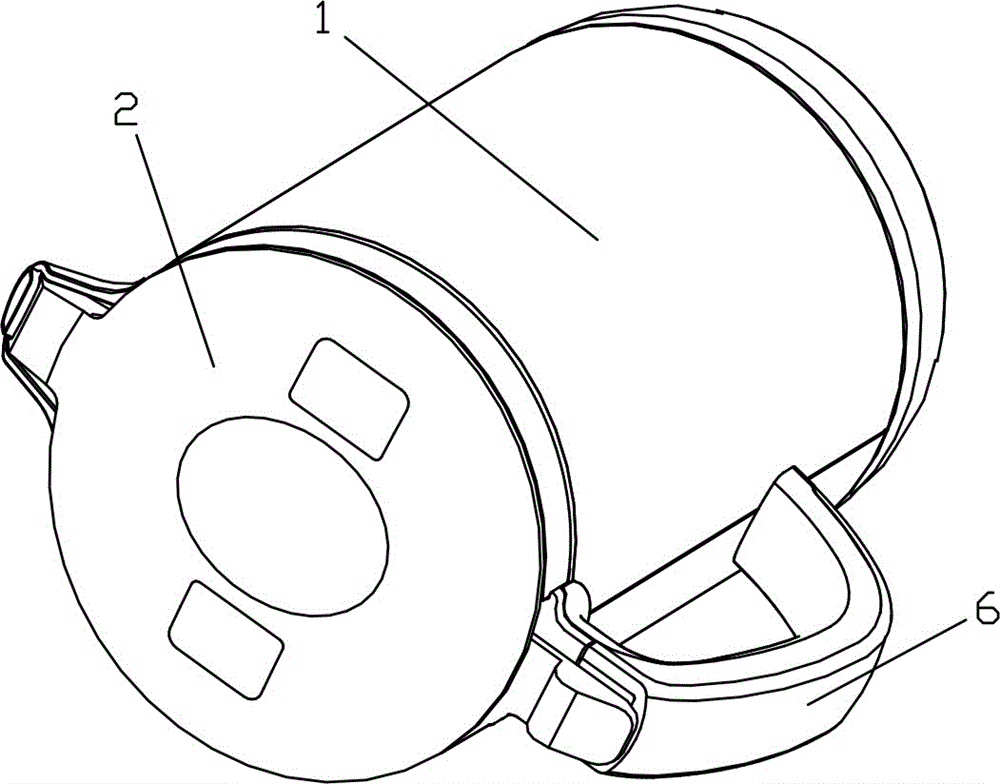

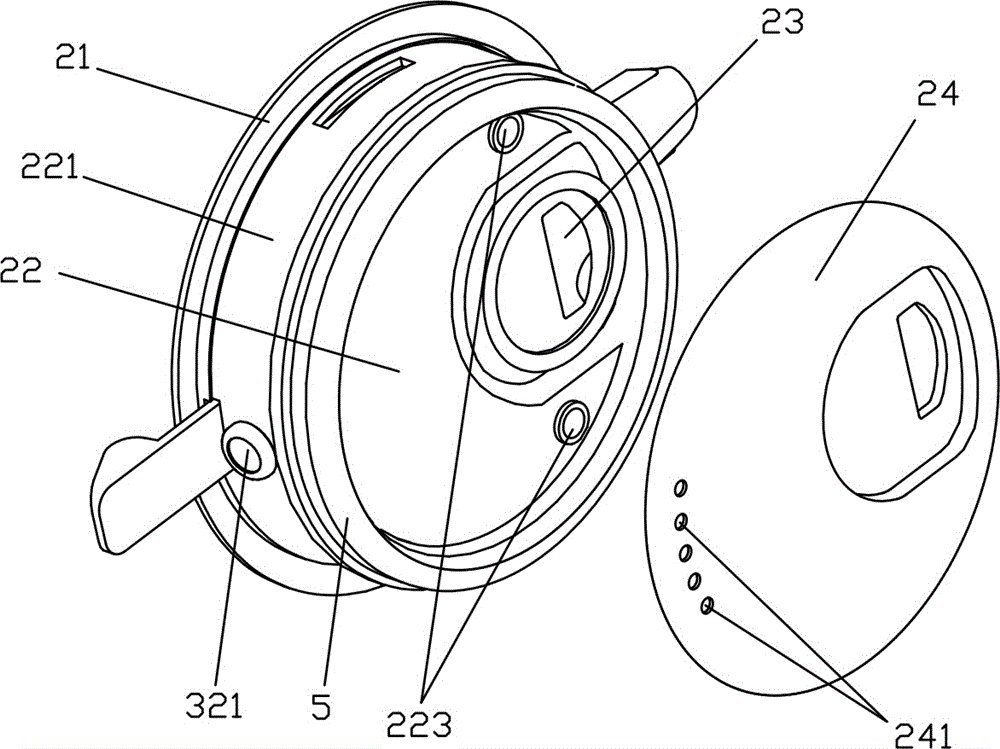

[0025] Such as Figure 1 to Figure 5 A safety spill-proof electric kettle shown includes a pot body 1 and a pot cover 2, the pot body 1 has a water-holding cavity 11, the pot cover 2 includes an upper cover 21 and a lower cover 22, the upper cover 21 and the lower cover A cover cavity 222 is formed between the covers 22, and a dumping and overflow prevention device 3 is provided in the cover cavity 222. The dumping and overflow prevention device 3 includes a plurality of exhaust and pressure relief pipes 31, and one end of each exhaust and pressure relief pipe 31 A plurality of exhaust holes 223 arranged on the lower cover 22 communicate with the water-containing inner cavity 11 respectively, and the other end of each exhaust pressure relief pipe 31 exhausts to the outside of the kettle cover 2, and the water-containing inner cavity 11 is filled with water to the highest level. After the water level line pot body is dumped, the highest pouring liquid level A is formed, at leas...

Embodiment 2

[0033] The difference between this embodiment and the first embodiment is that, if Figure 6 to Figure 8 , the lower cover 22 is provided with three exhaust holes 223, wherein two exhaust holes 223 are respectively located above the highest pouring liquid level A on both sides of the pouring bracket 6, and the other exhaust hole 223 is far away from the spout 23, and the three rows Air holes 223 can further ensure that at least one vent hole 223 is positioned above the pouring liquid level, and the more vent holes 223, the higher the probability that at least one vent hole 223 is positioned above the liquid level in the pot after pouring. The exhaust and pressure relief pipe 31 connected to the exhaust hole 223 on both sides of the tilting bracket 6 extends toward the side wall of the cover cavity opposite to the exhaust hole 223, and the exhaust and pressure relief pipe 31 away from the water outlet 23 circles around the side wall 221 Finally, the three are collected in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com