A device for adjusting a press nip

A technology of pressure device and regulating cylinder, which is applied in the direction of counter pressure device, press using rotating pressure member, press, etc., which can solve the problems such as inability to adjust, achieve the effect of improving pulp processing and avoiding stoppage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

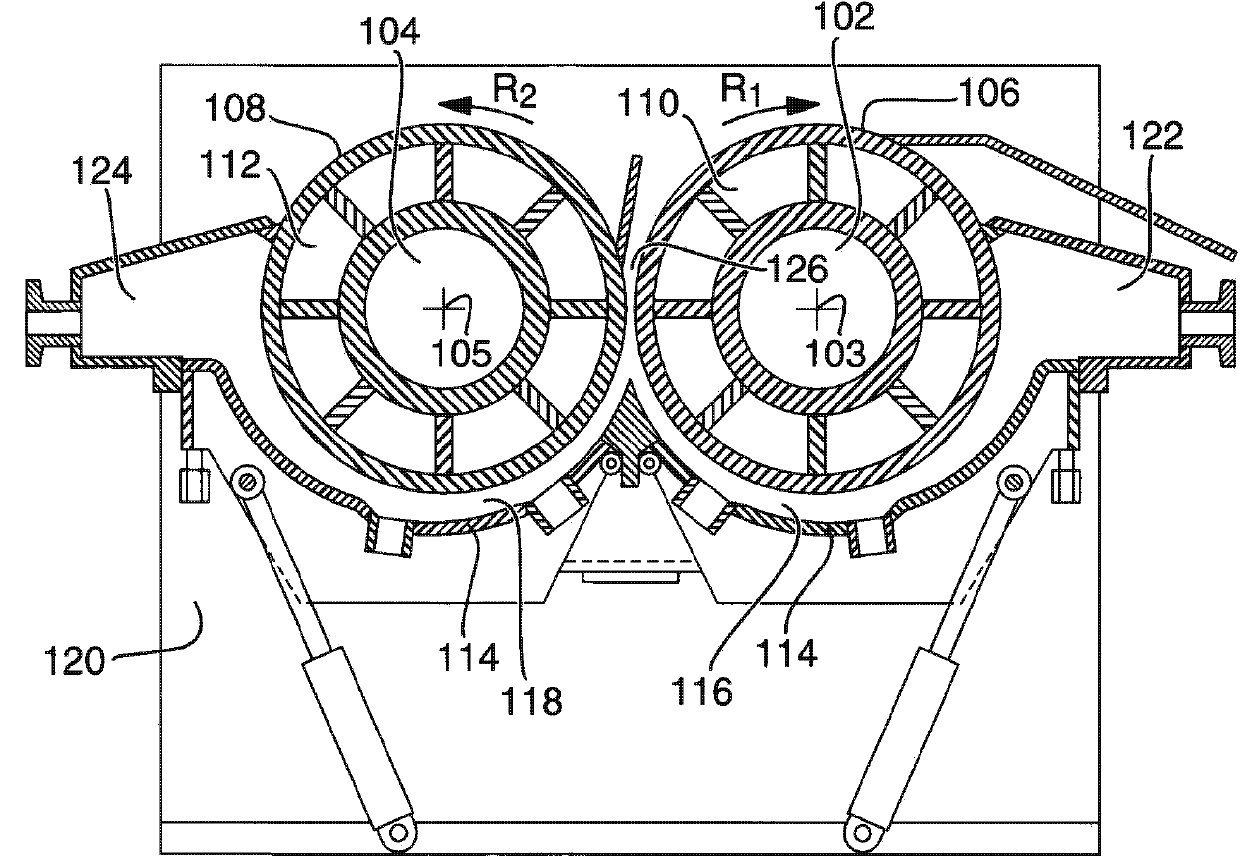

[0055] figure 1 An example of a plant for treating cellulose-containing pulp by washing, dewatering and pressing the pulp is schematically shown, in which plant a device according to the invention can be installed. The shown equipment may be referred to as a roll press. The apparatus comprises a first drum 102 in the form of a first press roll 102 and a second drum 104 in the form of a second press roll 104, each in a direction of rotation R 1 , R 2 is rotatable about an axis of rotation 103, 105 and has a permeable outer surface 106, 108 which may consist of at least one perforated plate (i.e. provided with holes), whereby the outer surface 106, 108 is sensitive to the filtrate from the pulp press is permeable. Each press roll 102, 104 may be provided with a plurality of filtrate channels 110, 112 extending along the axial extension of each press roll 102, 104 and disposed inwardly from the outer surface 106, 108 to Draw off the discharged filtrate. Each filtrate channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com