Contactless rotary pull switch

a rotary pull switch, contactless technology, applied in the direction of magnetic field change switch, pulse technique, transportation and packaging, etc., can solve the problems of increasing the cost and complexity of the switch, limiting the performance of the switch, and not being able to discern a distinct switching position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

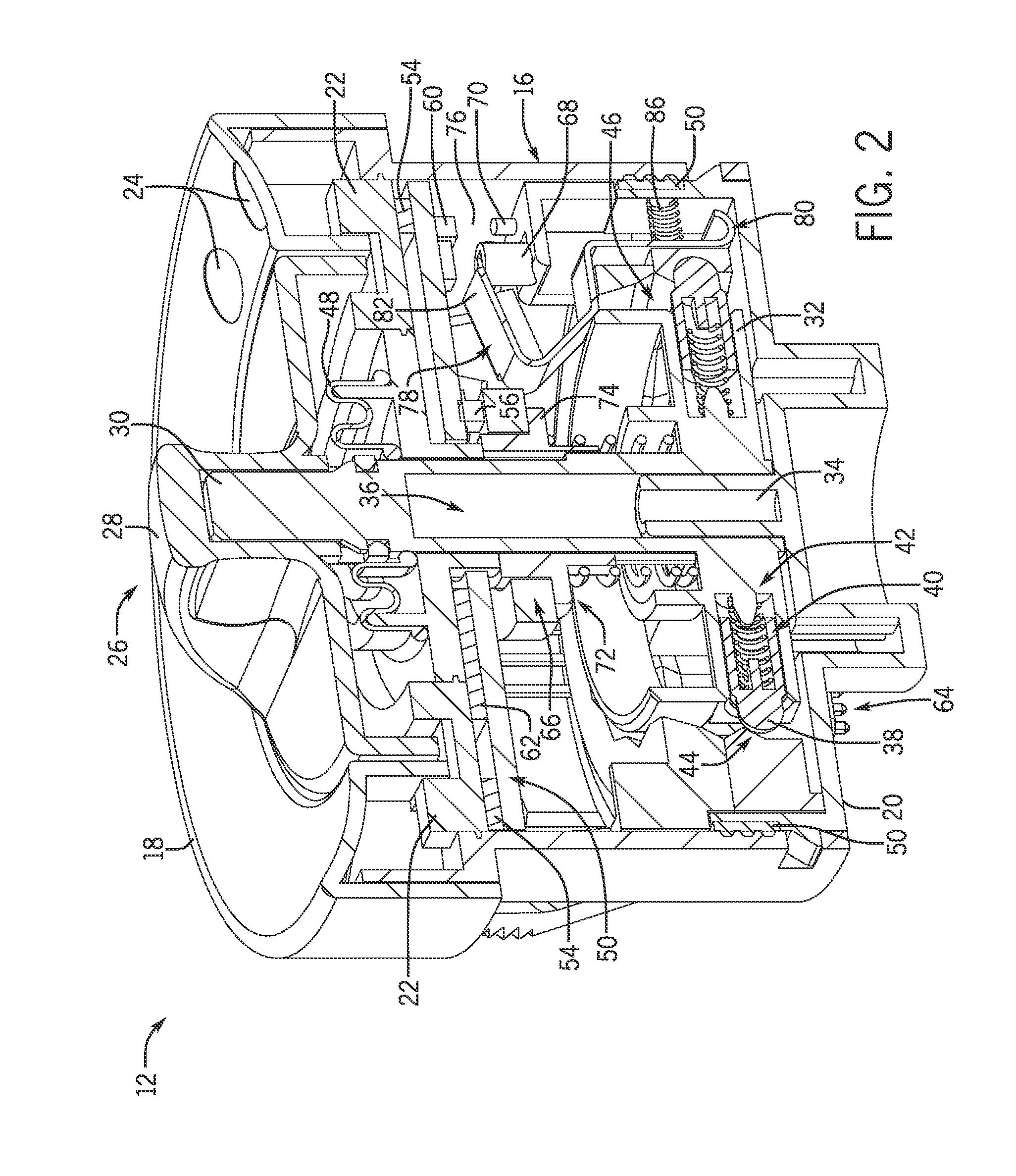

[0021]Embodiments of the invention are directed to a contactless rotary pull switch that utilizes magnetic sensing for both the rotary position and the pull position of the switch, so as to provide robust sensing of the rotary position and pull position. While a contactless rotary pull switch is described below with respect to its use as a vehicle lighting switch, it is recognized that the switch may be instead be used in other applications according to embodiments of the invention. Accordingly, it is to be understood that embodiments of the invention are not limited for use as vehicle lighting switches or for use in vehicles in general and that use of embodiments of the invention for other applications is understood to be within the scope of the invention.

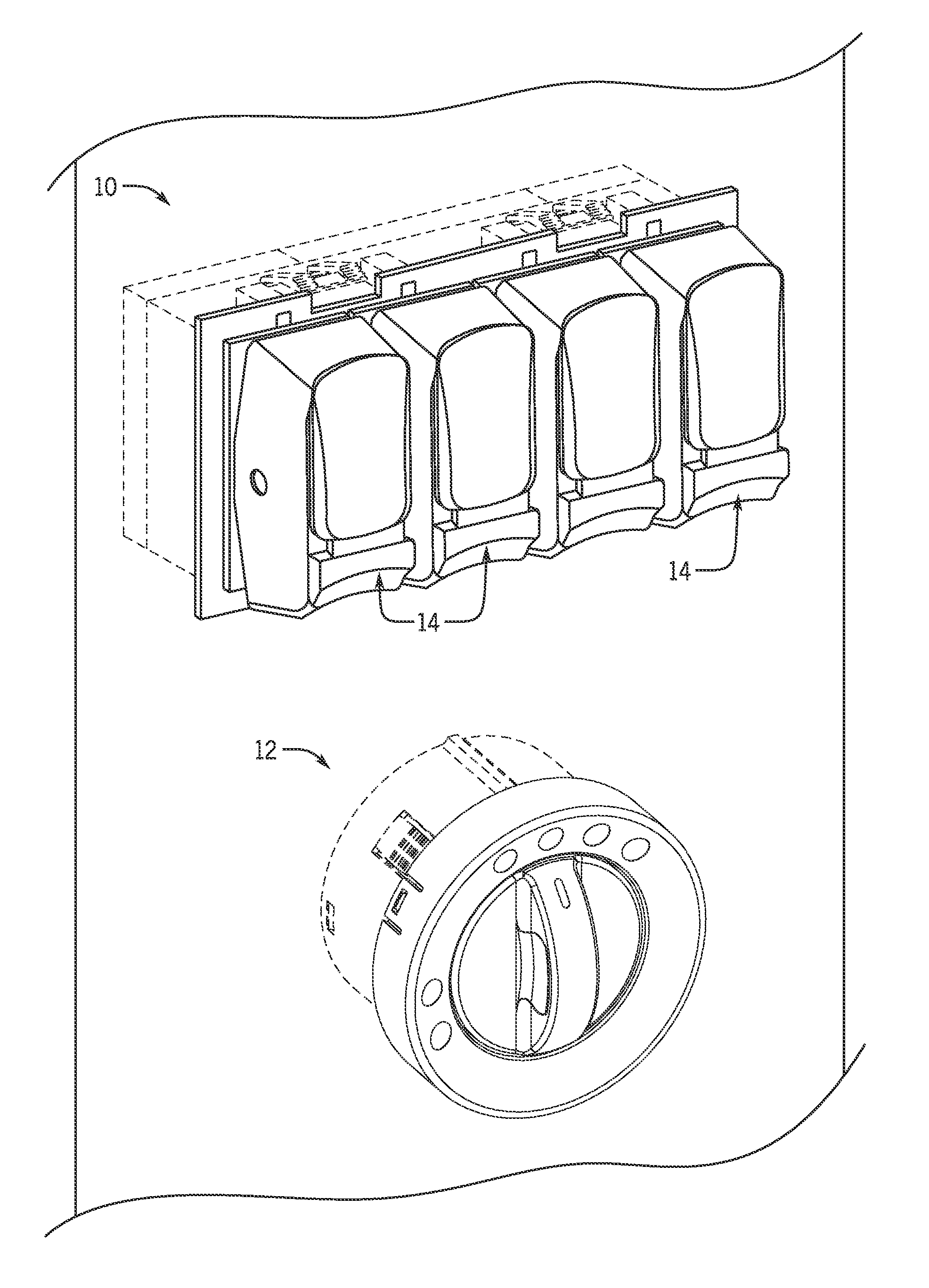

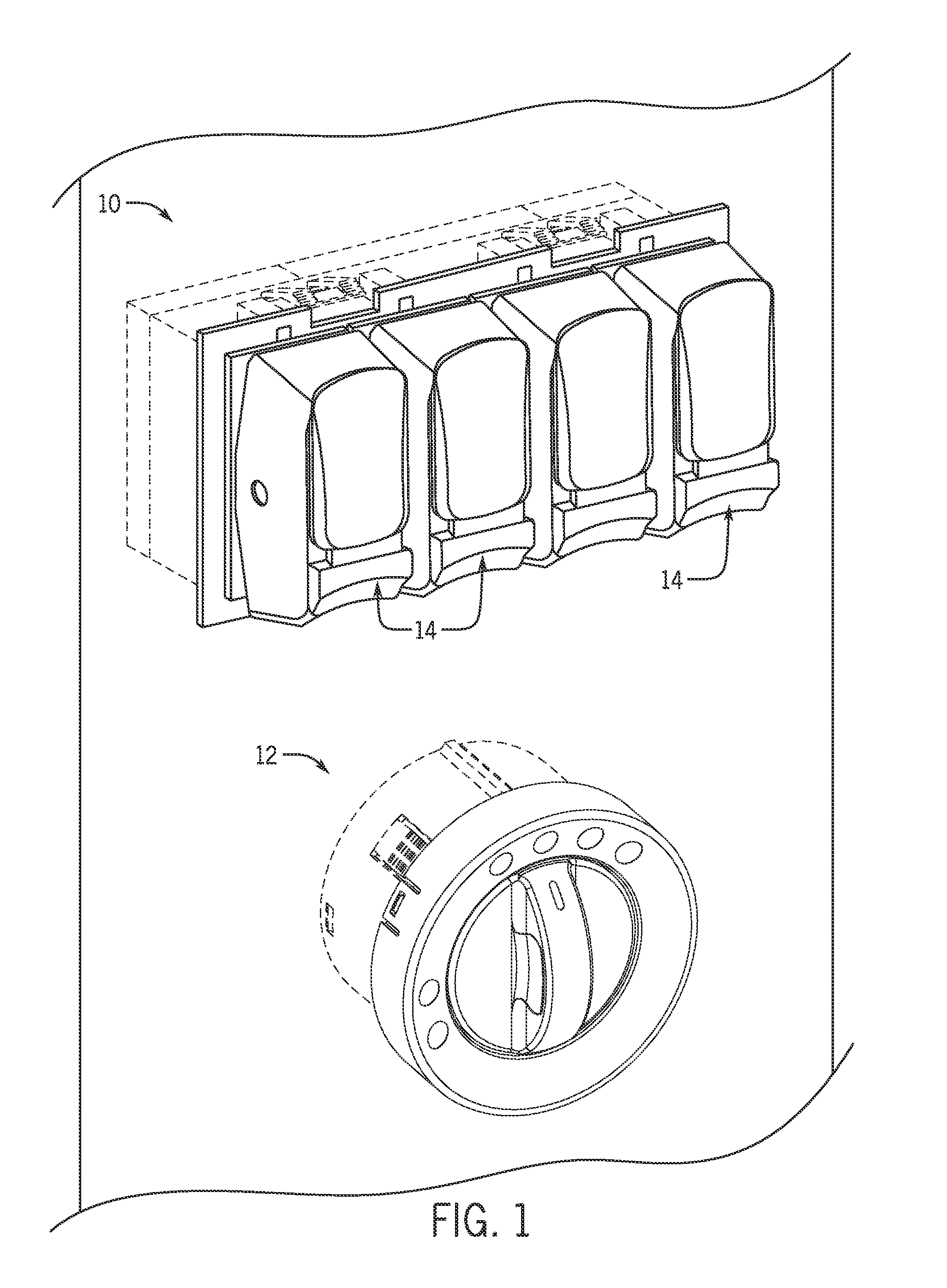

[0022]Referring to FIG. 1, the general layout of a portion of a vehicle dashboard 10 is shown such as might be useable with embodiments of the invention. The dashboard 10 includes a contactless rotary pull switch 12 and other vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com