Zipper with stamped metal zipper teeth

a zipper tooth and metal technology, applied in the direction of snap fasteners, slide fasteners, press-button fasteners, etc., can solve the problems of zipper teeth with zipper teeth with #2 zipper teeth not meeting the needs of the industry, structural strength, and zipper teeth that break and are easily forced away from zipper tape, etc., to achieve high structural strength, prevent zipper teeth from breaking, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

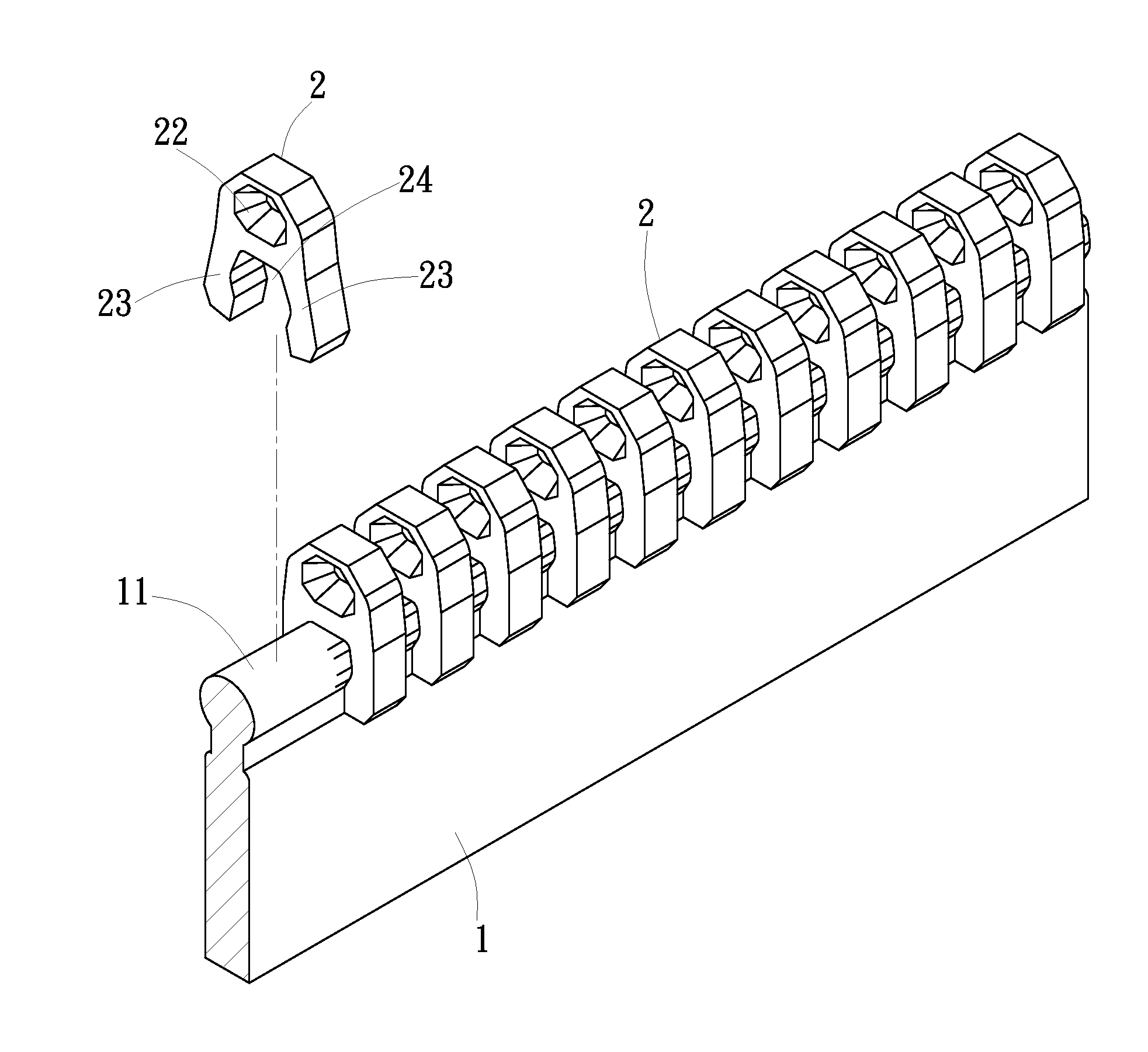

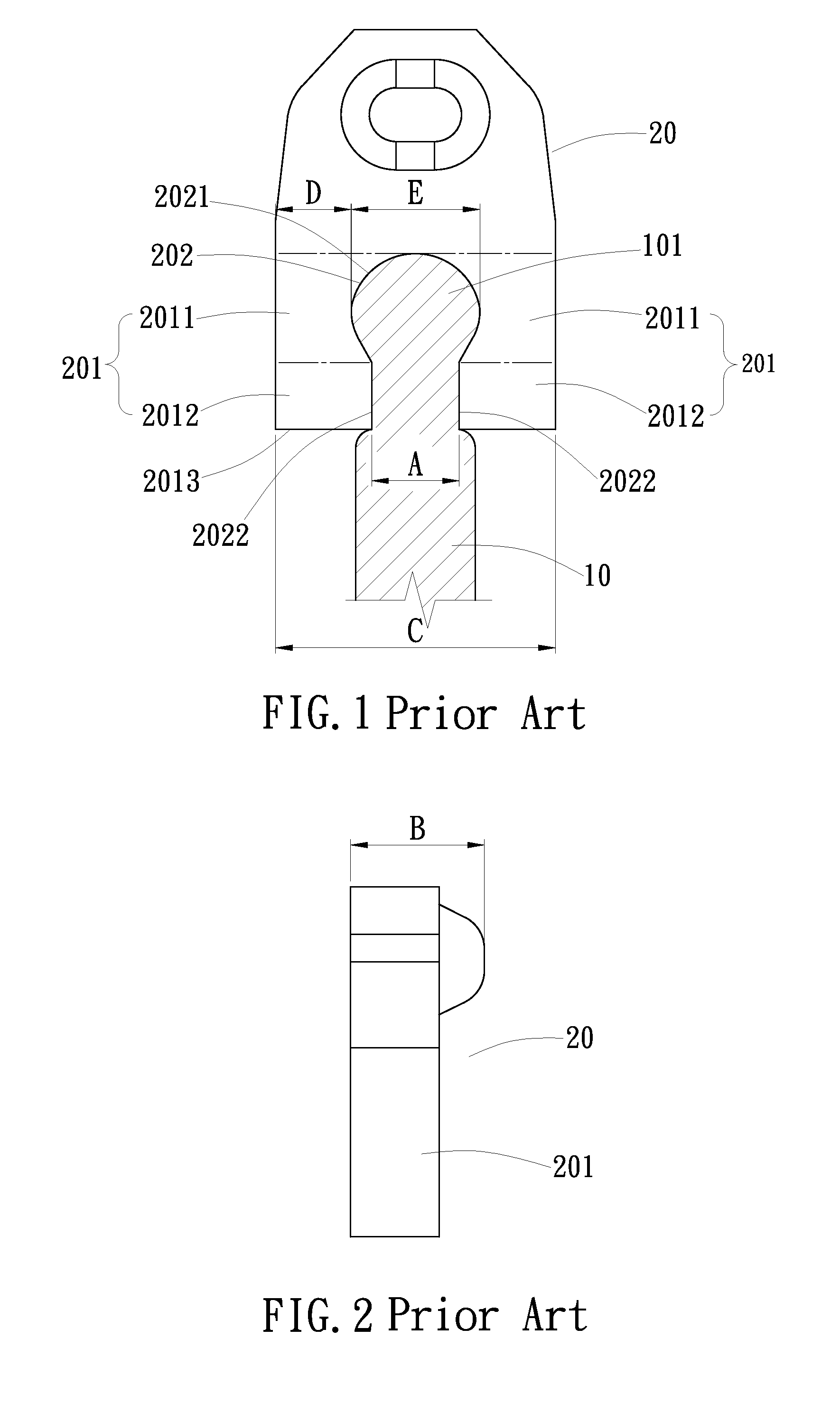

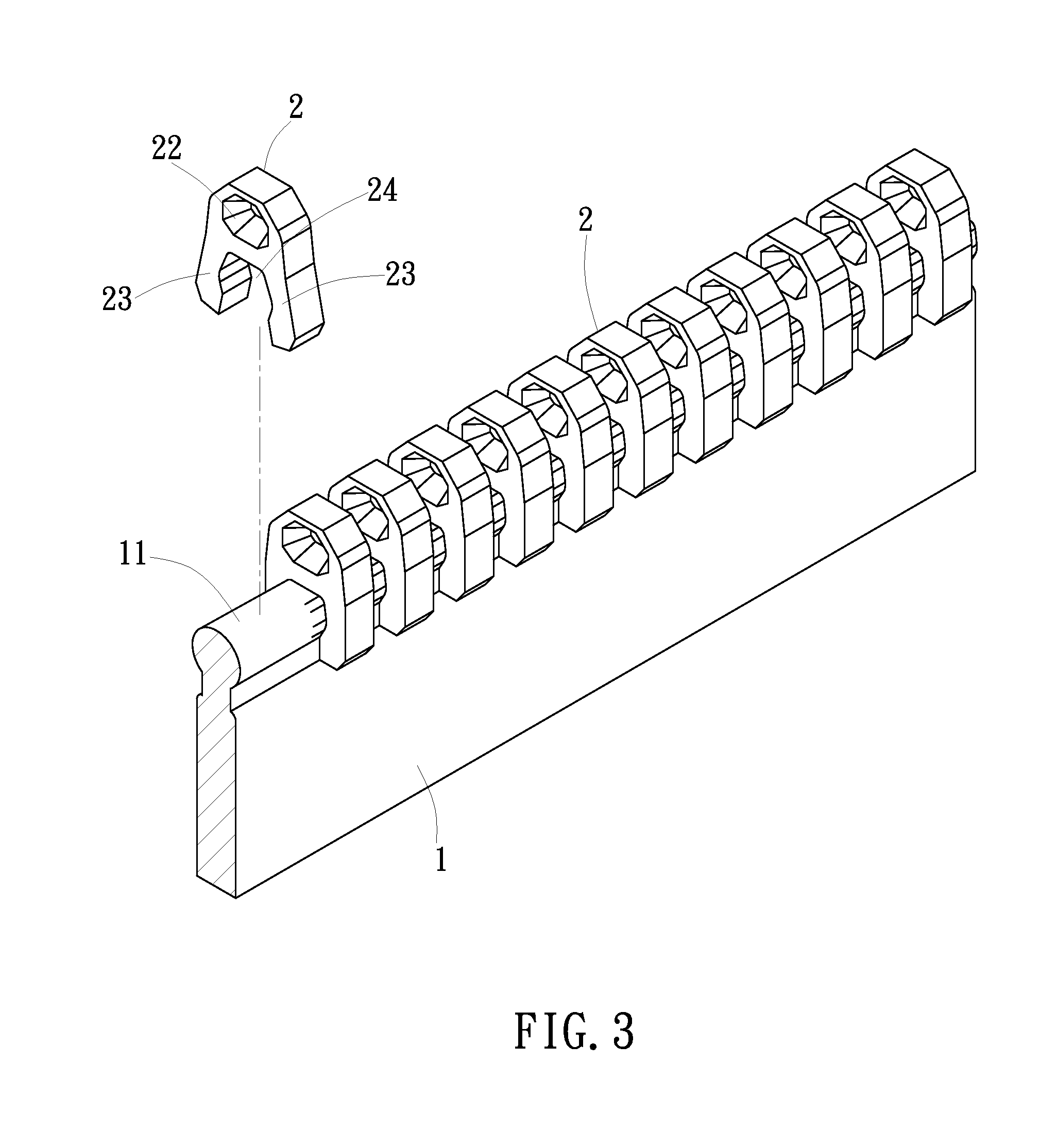

[0027]Referring to FIG. 3, a zipper with stamped metal zipper teeth in accordance with the present invention has stamped metal teeth mounted on each of two zipper tapes thereof. In a first embodiment of the present invention, the zipper comprises two zipper tapes 1, and a plurality of zipper teeth 2 mounted on one lateral side edge of each zipper tape 1 in a line. The zipper tapes 1 are fabric tapes, each having a rib 11 of circular cross section extending along one lateral side edge thereof for securing the zipper teeth 2. The zipper teeth 2 are engagement members made of metal by stamping for fastening to the ribs 11 of the zipper tapes 1, as shown in FIG. 3 and FIG. 4. Each zipper tooth 2 comprises a polygonal engagement protrusion 21 located on one side of a front end thereof (see FIG. 7), and a polygonal engagement recess 22 located on an opposite side of the front end. When the two zipper tapes 1 are driven by a sliding member (zipper slider) to move toward each other, the eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com