Apparatus for Continuous Casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

[0062]To facilitate comprehension, the same reference numbers have been used, where possible, to identify identical common elements in the drawings. It is understood that elements and characteristics of one form of embodiment can conveniently be incorporated into other forms of embodiment without further clarifications.

DETAILED DESCRIPTION OF SOME FORMS OF EMBODIMENT

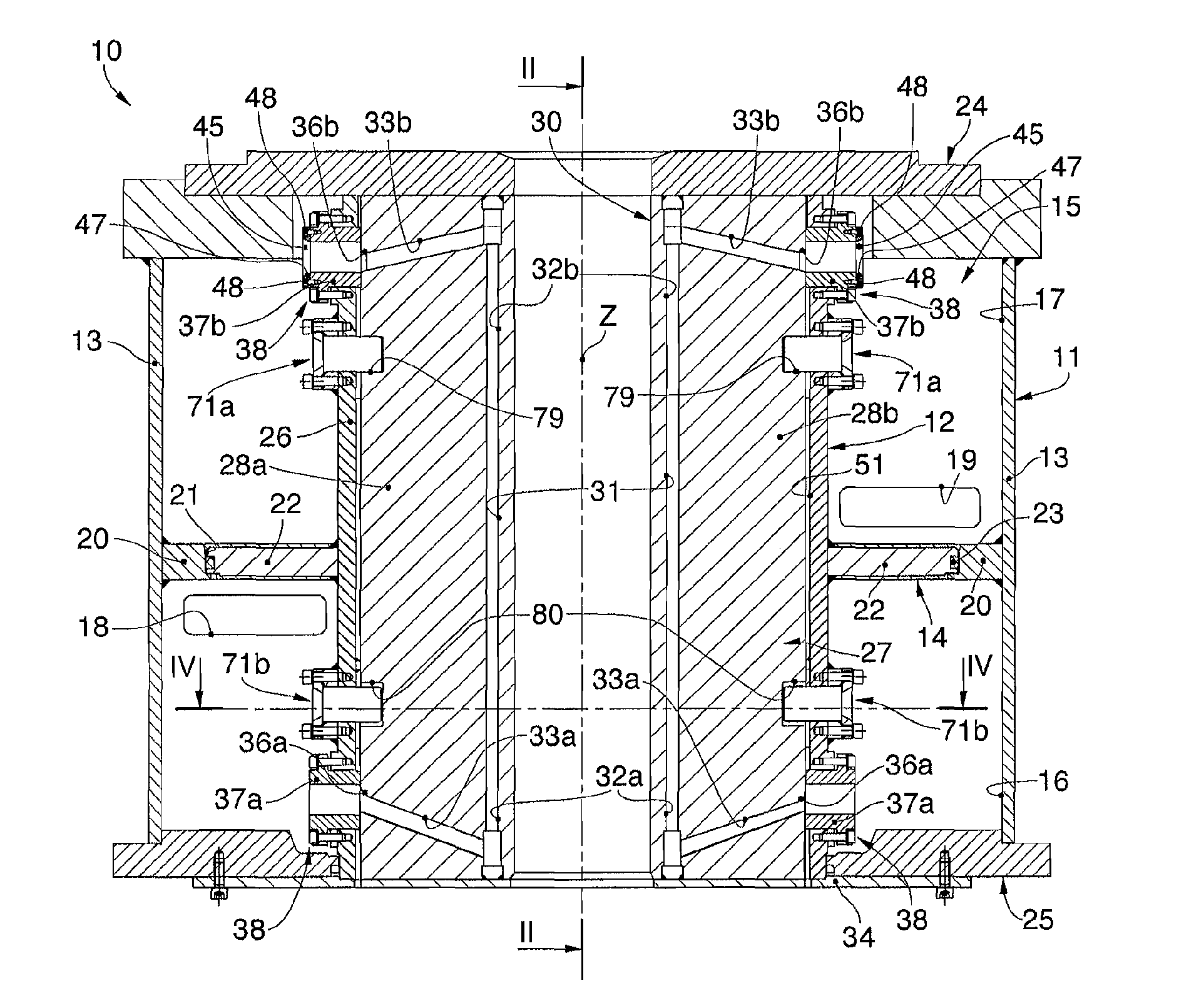

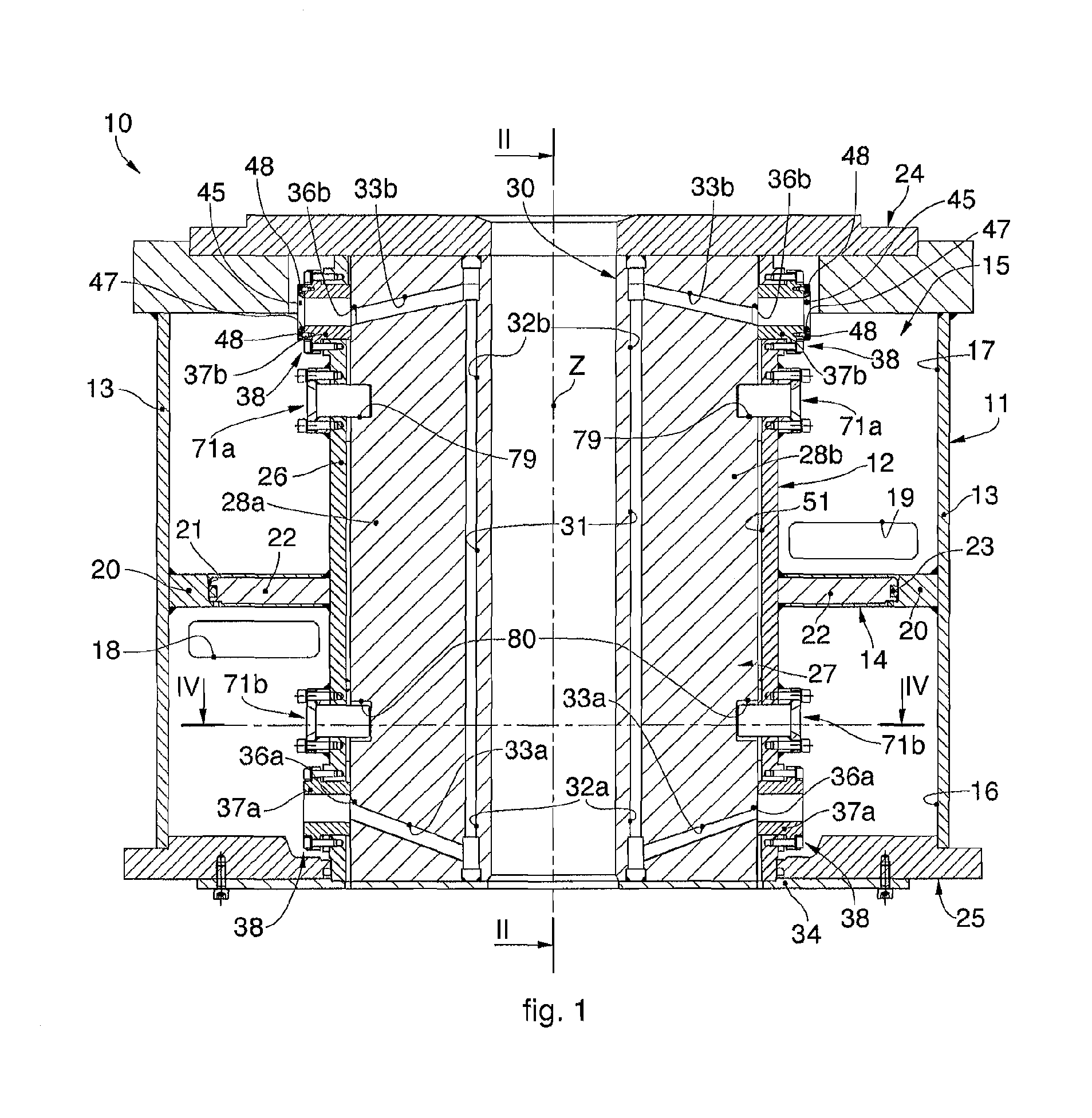

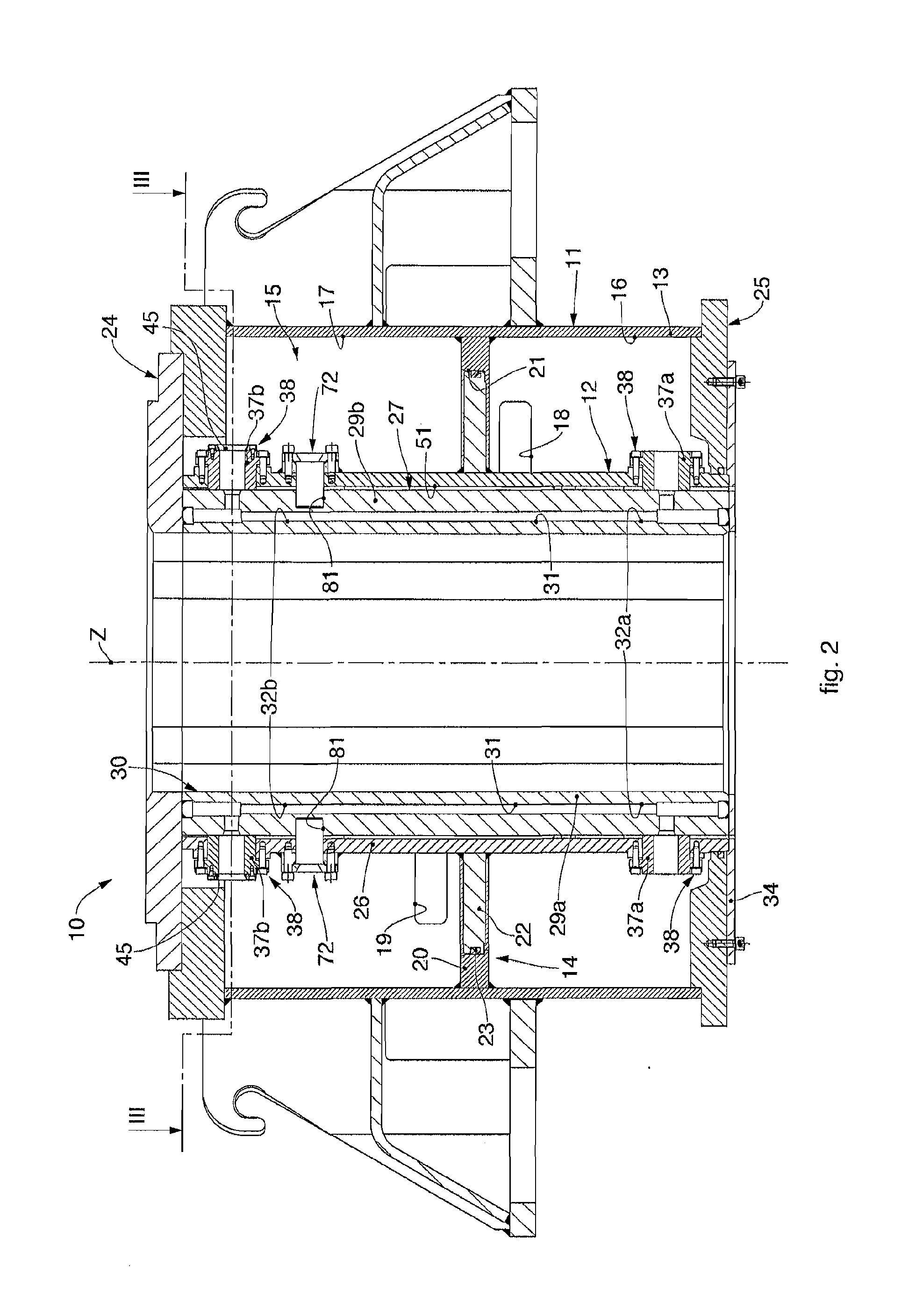

[0063]With reference to FIG. 1 an apparatus for continuous casting is indicated in its entirety by the reference number 10 and comprises a support structure or mold body 11, to which a mold 12 is associated, in this case, of the plate type. The mold body 11 also allows to install molds of the tubular type.

[0064]The mold body 11 is provided with a containing casing 13 in which, during use, the mold 12 is inserted. Between the containing casing 13 and the mold 12 a closed chamber 15 is defined, to contain the cooling water. The containing casing 13 is closed at the top by an upper flange 24 and below by a lower flange 25.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com