Method of forming sole and sole structure with shoe nail coupled thereto and sole structure with shoe nail

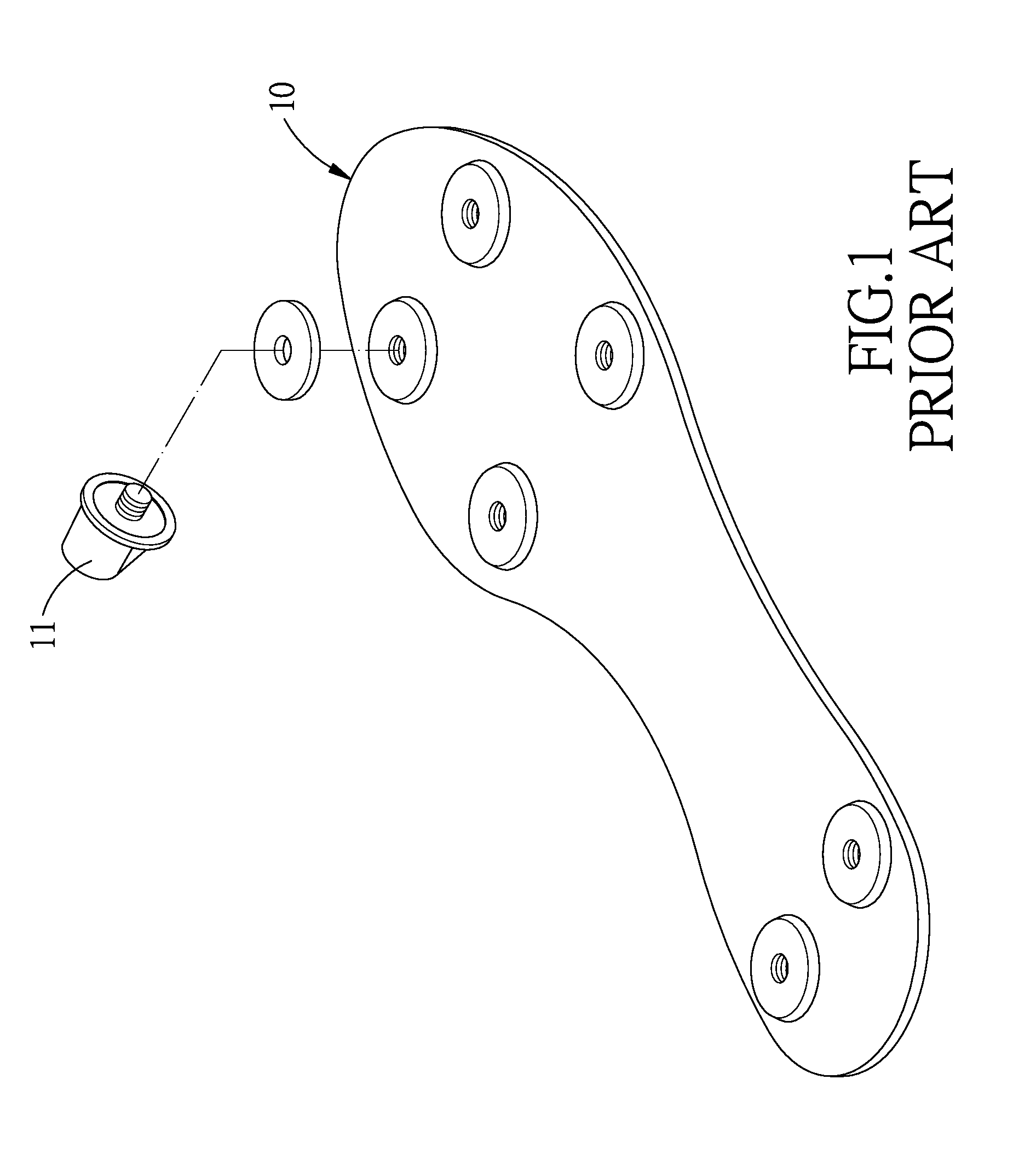

a technology of sole structure and shoe nail, which is applied in the field of manufacturing parts and components of shoes, can solve the problems of unfit mass production, unsuitable for mass production and achieve the effects of low coupling stability, insufficient grip, and complex manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

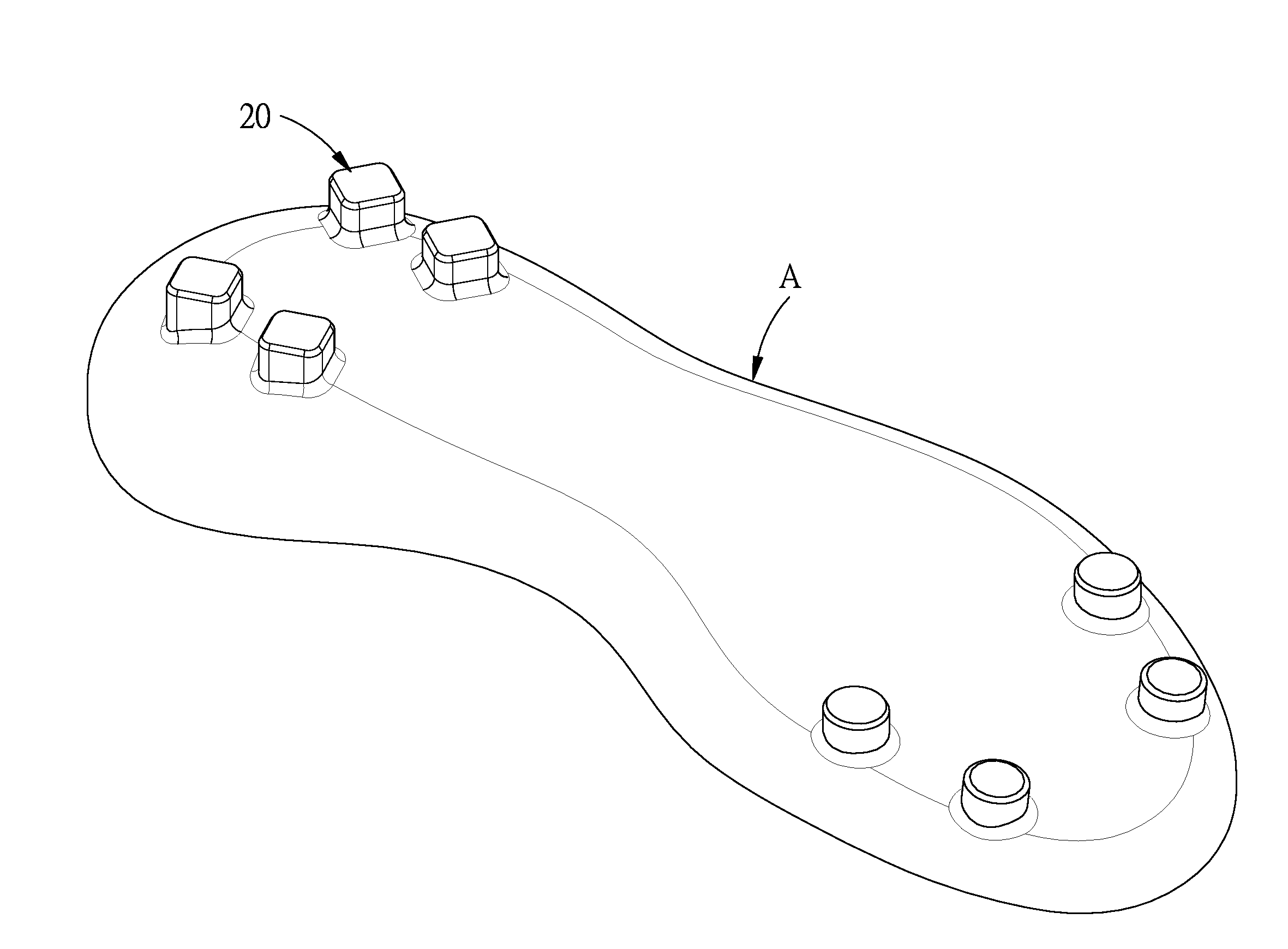

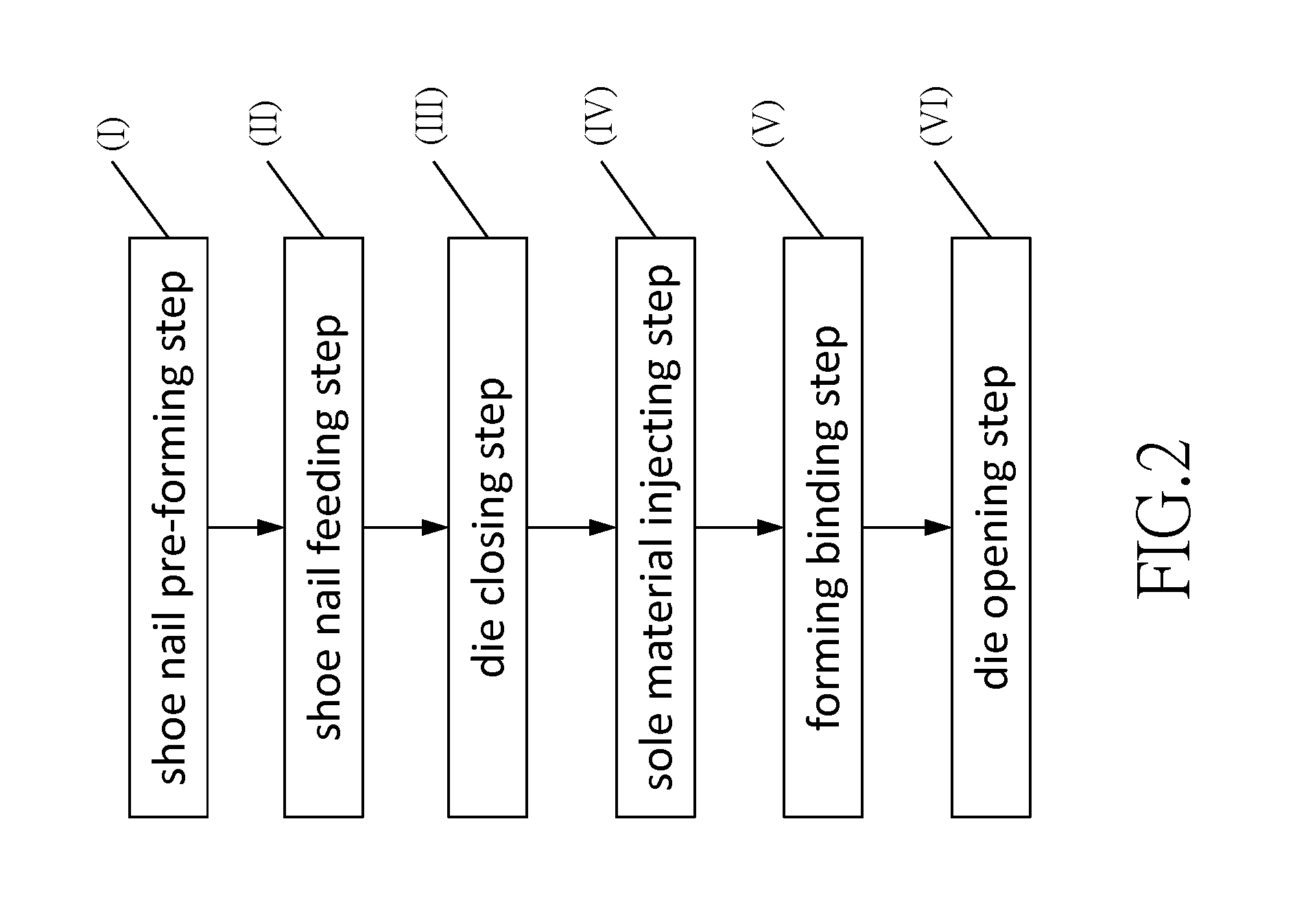

[0025]The present invention provides a method of forming a sole and a sole structure with shoe nails coupled thereto, as shown in FIGS. 2-6. The method comprises the steps below.

[0026]Shoe nail pre-forming step (I): forming a shoe nail 20. In this embodiment, the shoe nail 20 is made of rubber. The shoe nail 20 has a head 21 and a coupling segment 22. The coupling segment 22 extends in an axial direction X. A radial direction Y is perpendicular to the axial direction X. The outer diameter of the coupling segment 22 is less than the outer diameter of the head 21, such that a filling ring portion 23 is formed between the head 21 and the coupling segment 22. One end of the coupling segment 22 is connected to the head 21. A slot 221 is disposed at the other end of the coupling segment 22, wherein the slot-disposed end of the coupling segment 22 is different from the head-connected end of the coupling segment 22. The slot 221 has a slot bottom 222 and a slot inner diameter D1. The slot 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| outer diameter | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

| coupling stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com